A method and tooling for batch processing arc-shaped grooves by using a lathe

A lathe, arc-shaped technology, applied to milling devices, metal processing equipment, metal processing mechanical parts that can be installed on the machine tool, etc. The effect of repeated clamping of products, simple and convenient operation, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

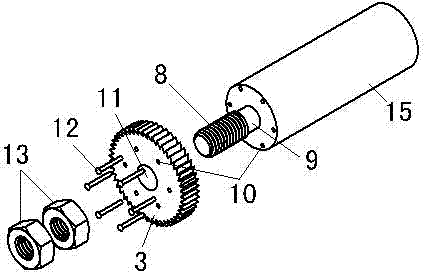

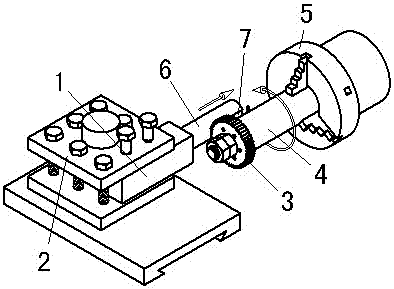

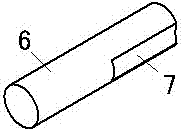

[0019] The method of the present invention for batch processing of arc-shaped straight grooves using a lathe is as follows: figure 1 As shown in the figure (the straight arrow in the figure is the moving direction of the workpiece 6 to be processed, and the circular arrow is the rotation direction of the milling cutter 3), the method is to clamp the workpiece fixture 1 on the lathe tool holder 2; then install the milling cutter 3 The milling cutter clamping assembly 4 is clamped on the three-jaw chuck 5 of the lathe; during processing, the workpiece 6 to be processed is inserted into the workpiece positioning hole 14 of the workpiece fixture 1, and the lathe is started. The lathe spindle drives the milling cutter 3 to rotate counterclockwise and pass The lathe tool holder 2 drives the workpiece 6 to be processed to move radially and axially, and the radial movement can adjust the amount of cutter 3 to change the depth of the arc-shaped straight groove 7; the axial movement can co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com