Welding gun head for regulating position of welding gun

A welding torch and head technology, applied in the field of welding torch head, can solve problems such as the complex structure of the welding torch head, achieve fully automatic and efficient welding, reduce welding blind spots, and ensure the effect of forming and welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

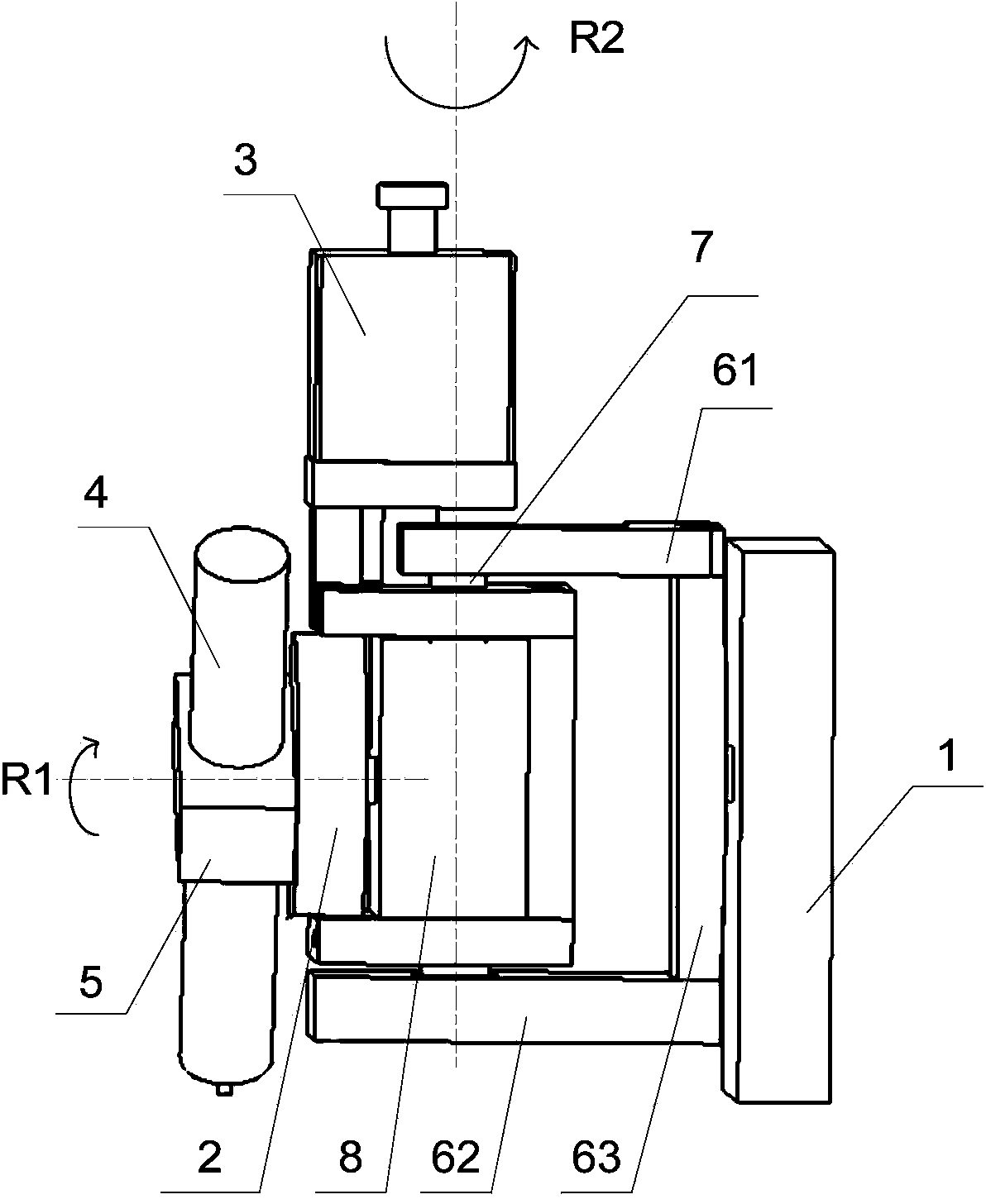

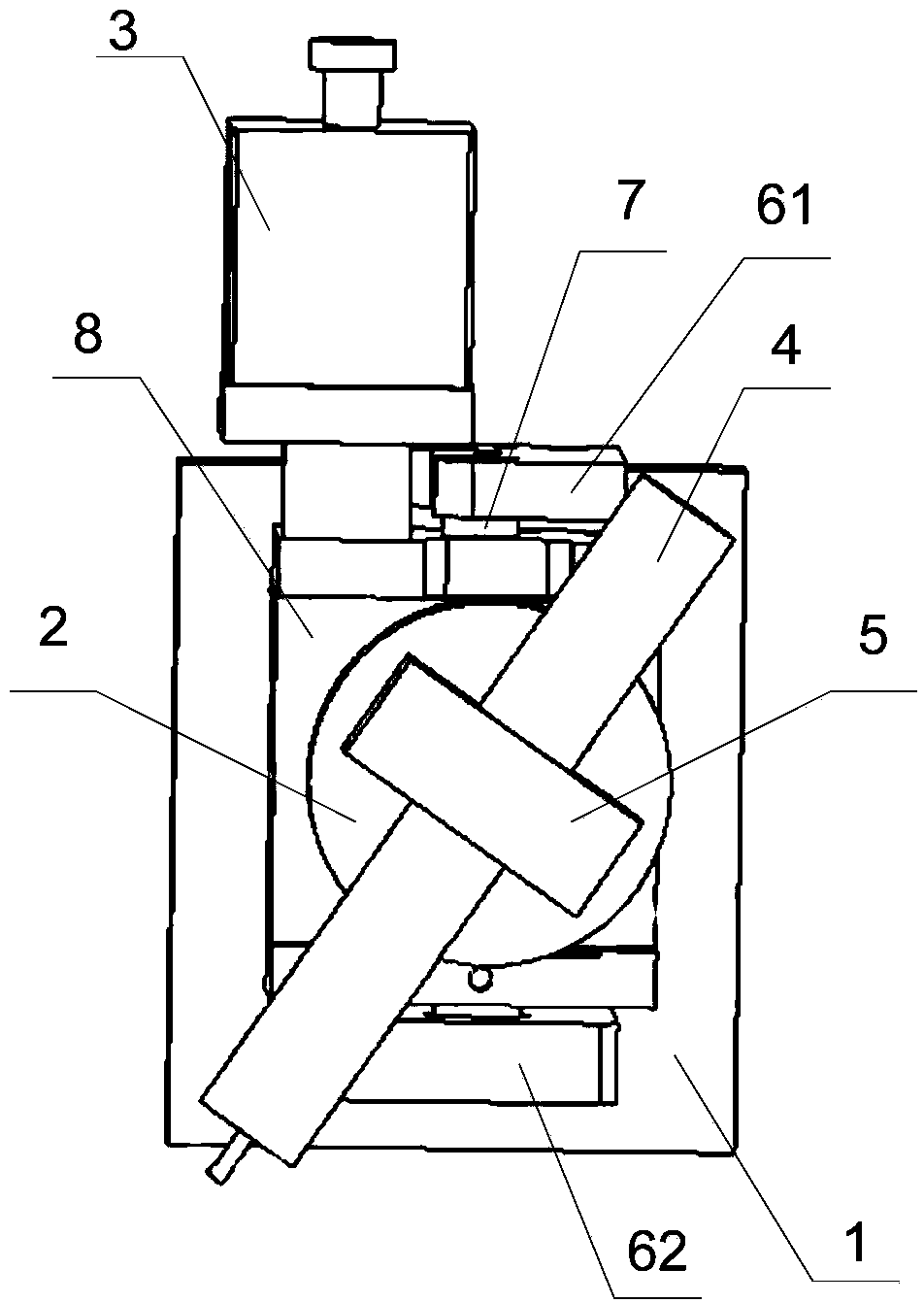

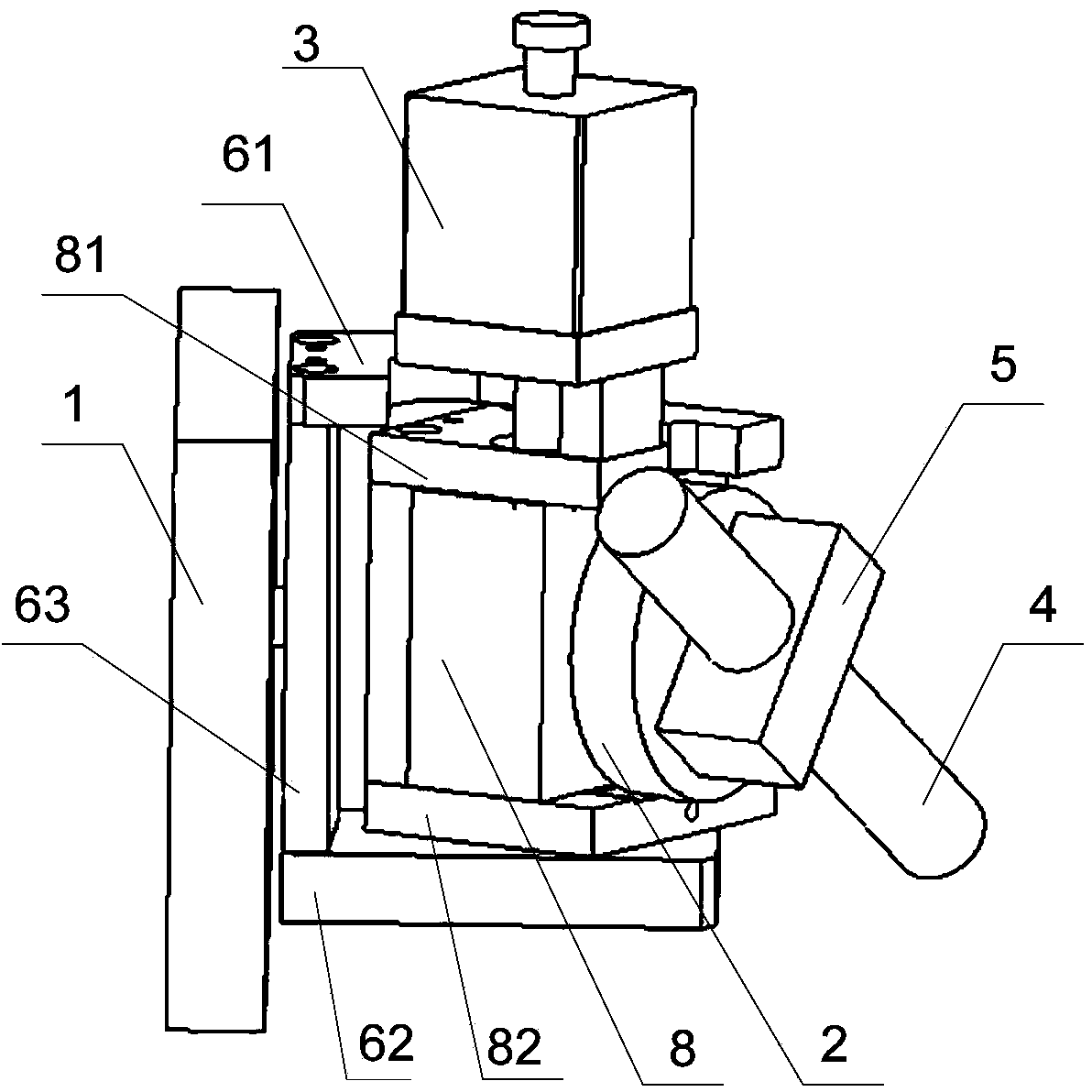

[0034] figure 1 It is a three-dimensional schematic view viewed from the side of a welding torch head according to an embodiment of the present invention, Figure 2 to Figure 4 for figure 1 Perspective views from different angles of the welding head shown. like Figure 1-4 As shown, the welding torch head for adjusting the position of the welding torch in the embodiment of the present invention includes a connecting plate 1, an angle pendulum 2, an angle pendulum motor 3 and a welding torch holder 5 for installing a welding torch 4, and the welding torch holder 5 is connected to Angle pendulum 2 also comprises the semi-I-shaped frame that is connected on the connecting plate 1, and frame comprises upper plate 61, lower plate 62 and the base plate 63 that is connected between upper p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com