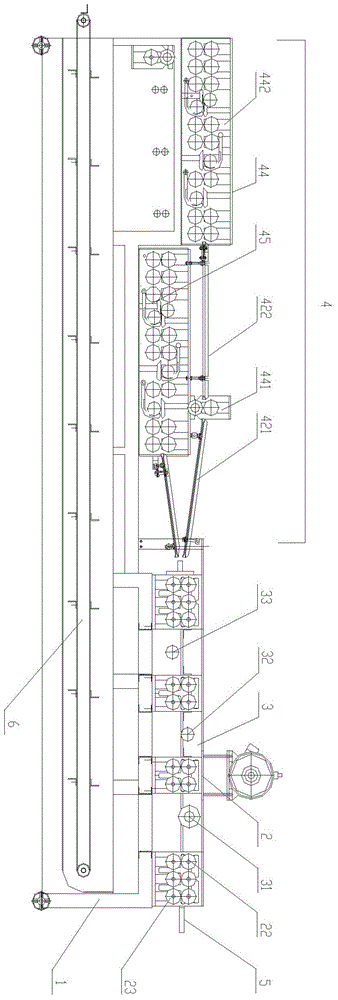

Combined type bamboo strip wire drawing machine

A wire drawing machine and combined technology, which is applied in the field of combined bamboo chip wire drawing machines, can solve the problems of low utilization rate of equipment human resources and high production costs, and achieve the effects of reducing the number of manual operations, improving production efficiency and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

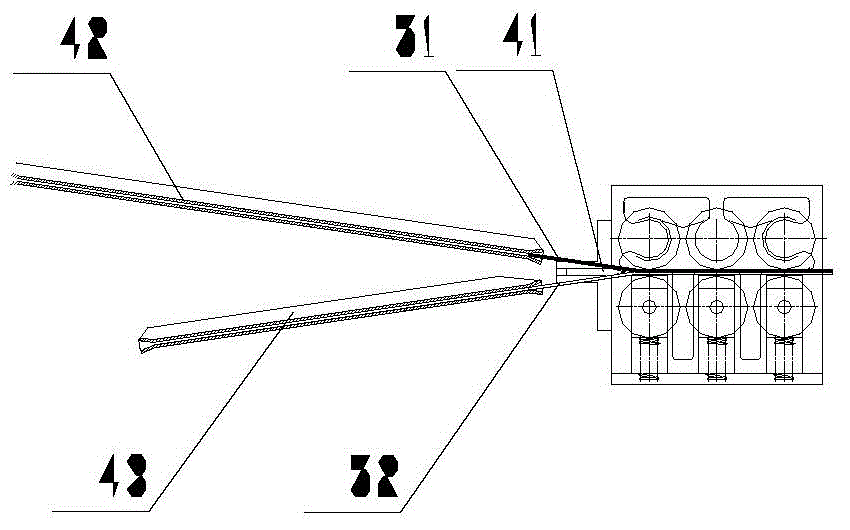

[0023] In order to facilitate the extraction of the blue noodle 51 and yellow noodle 52 after wire drawing, the blue noodle drawing device 44 and the yellow noodle drawing device 45 are arranged adjacently up and down, combining the molding characteristics of the green noodle 51, the green noodle Sheet wire drawing device 44 comprises two groups of green noodle sheet lead troughs 42, being respectively the first blue noodle sheet lead trough 421 and the second blue noodle sheet lead chute 422, the feed end of the first blue noodle sheet lead trough 421 is corresponding to the dividing The green dough sheet 51 outlet end of sheet knife 41, be provided with green dough sheet transition feeding device 441 between the first green dough sheet guide chute 421 and the second blue dough sheet guide chute 422, the outlet of the second blue dough sheet guide chute 422 The material end is connected with the green noodle drawing machine 442.

Embodiment 2

[0025] In order to ensure a good environment during production, the technical solution of this embodiment is to install a waste conveyor belt 6 on the bottom of the support frame 1 along the axial direction, and transport the waste and bamboo chips generated during the processing to the designated location for storage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com