Wrap angle laying method applied to ceramic chip group packaging and wrap angle laying device

A technology of wrapping corners and tiles, which is applied in the field of corner wrapping methods and corner wrapping devices for tile group packaging, and can solve the problems of inability to insert wrap corners with protective sheets to wrap tile groups, discontinuous movement process, price and Low profit and other problems, to achieve the effect of improving the efficiency of wrapping angle, filling the gap in the industry, and high placement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

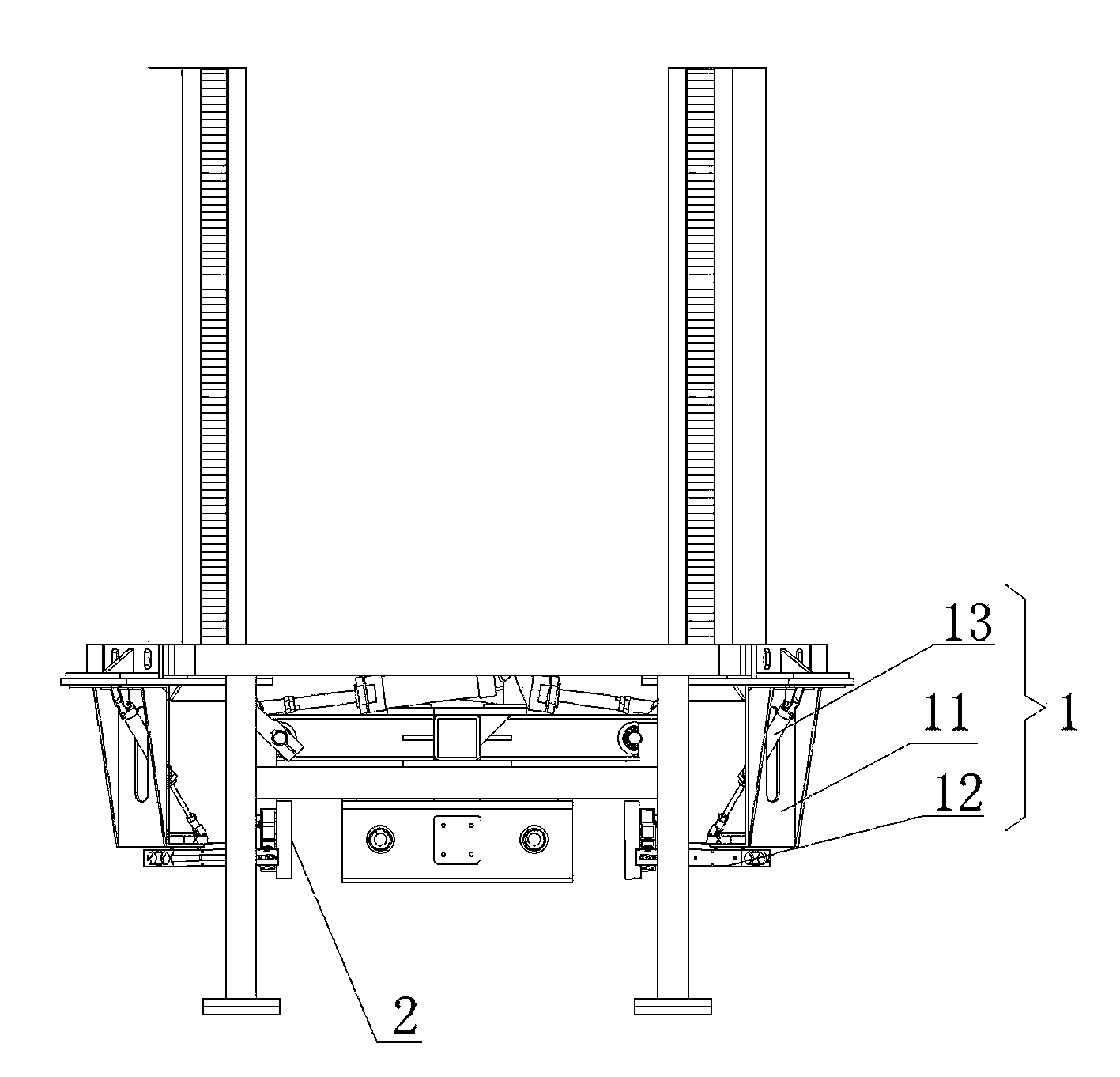

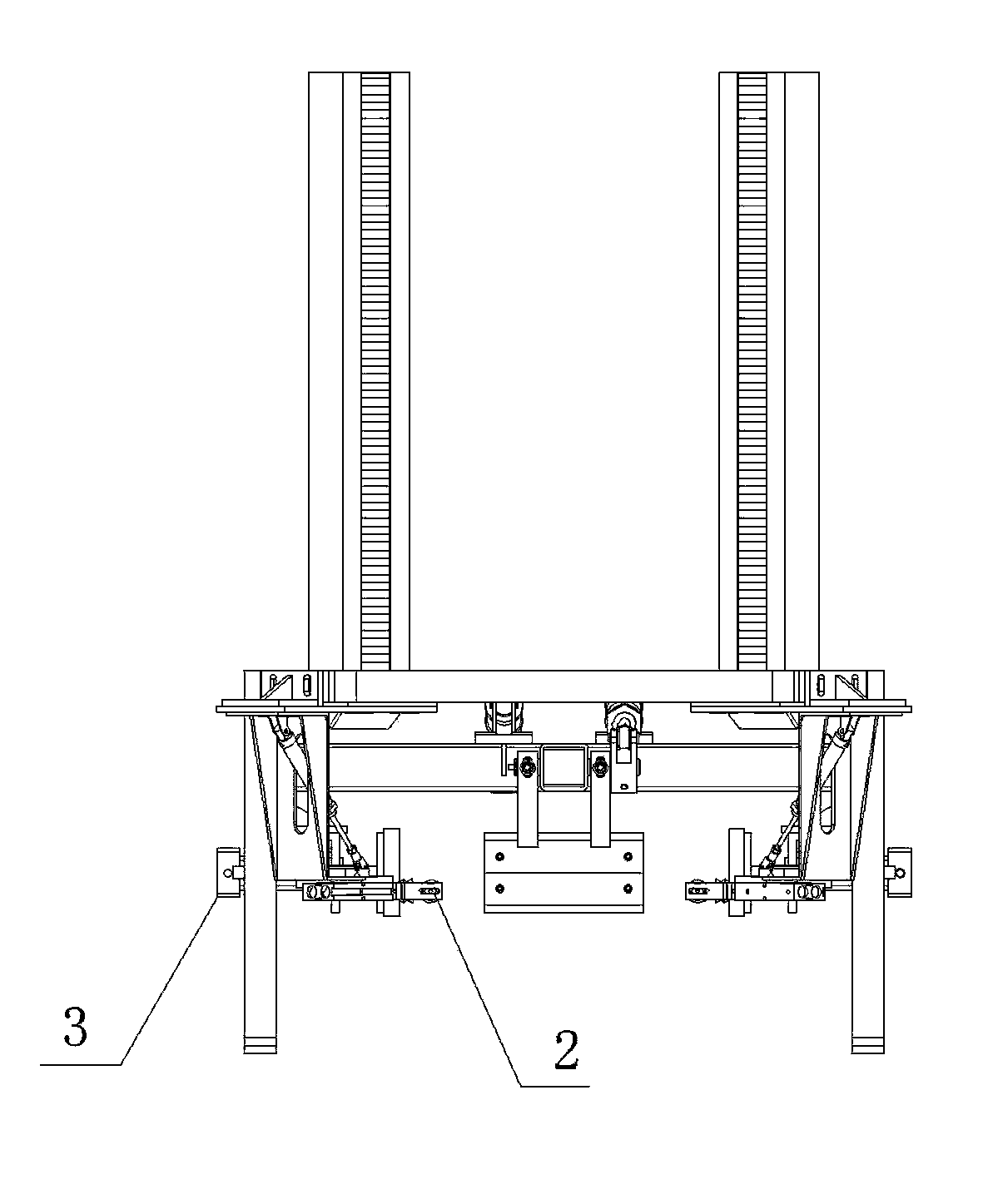

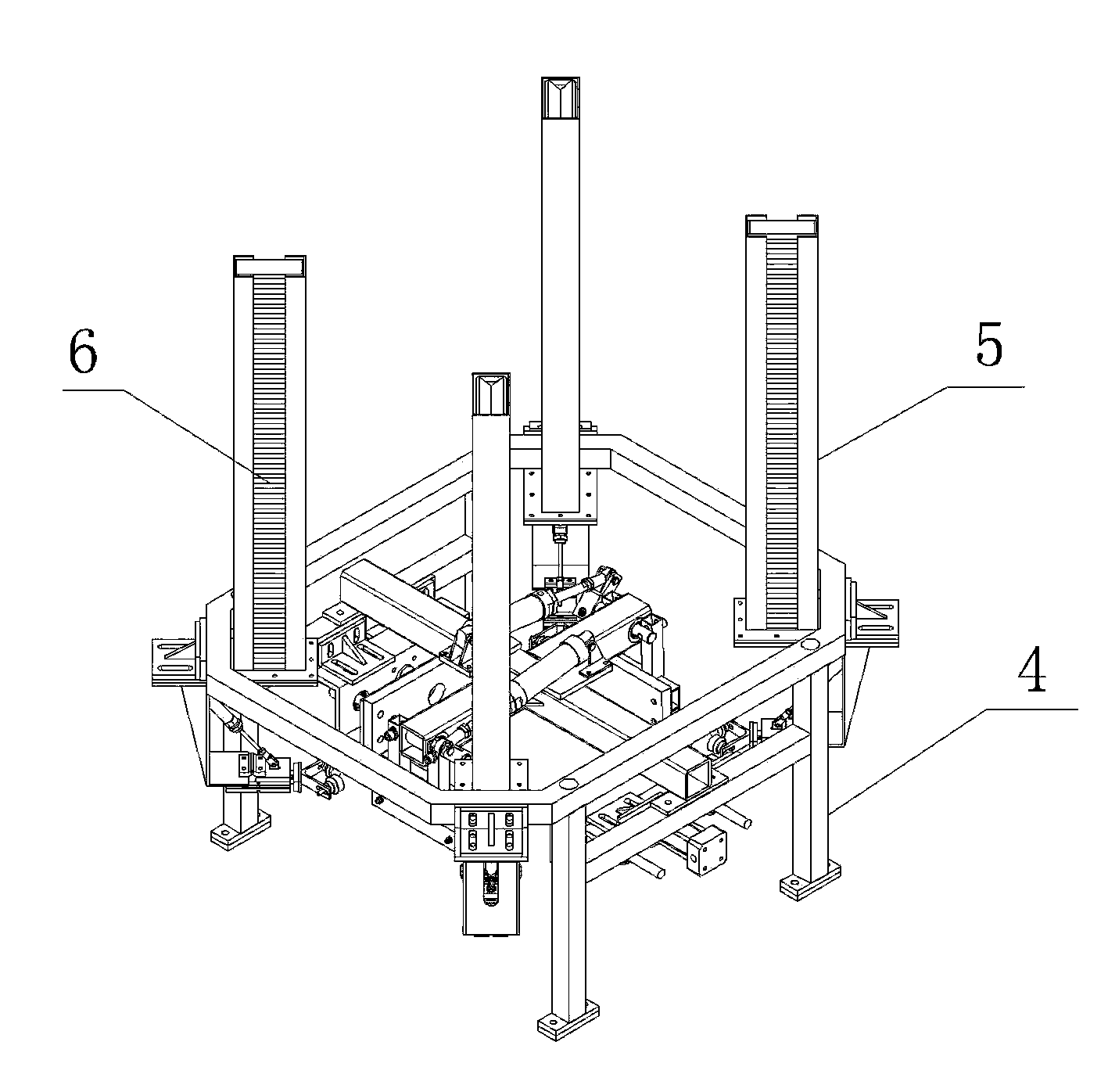

[0039] In order to further illustrate the essence of the present invention, the specific embodiments of the present invention are described as follows in conjunction with the accompanying drawings.

[0040] method embodiment

[0041] A method of wrapping corners applied to the packaging of tile groups, which is to automatically place the corners on the corners of the tile group through a corner feeding device, and the corners are corners with protective sheets, that is, in The upper and / or lower sides of the tile group also have corner-wrapped end faces to form double guards or single guards with corners. For the convenience of placing the wrapping corner on the corner of the tile group, the wrapping end face is obliquely arranged on the upper and / or lower ends of the wrapping corner, so that the opening of the wrapping corner is opened outward; A flexible buffer protecting the tile stack. In this embodiment, it is preferable that both upper and lower ends of the wrapping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com