Anti-fouling type muffler strengthening device

A technology for strengthening devices and mufflers, applied in mufflers, exhaust devices, machines/engines, etc., can solve problems such as poor noise reduction effect, ensure the sealing, dustproof and waterproof effect, improve the muffler effect, and prolong the service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below with reference to the embodiments and accompanying drawings, but the embodiments of the present invention are not limited thereto.

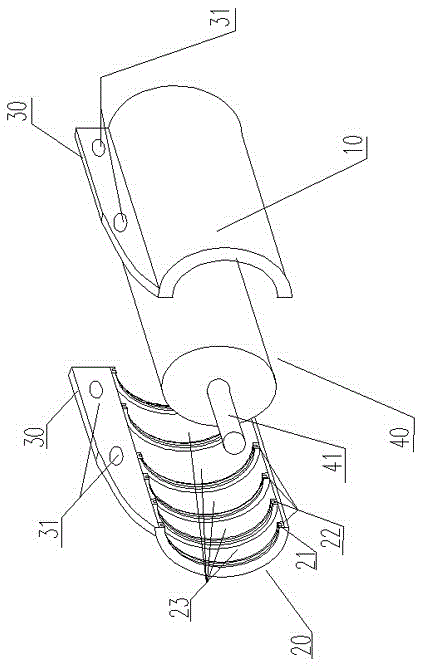

[0017] Embodiment 1 of the present invention is, as figure 1 As shown, the first shell 10 and the second shell 20 are included, the first shell 10 and the second shell 20 are both semi-circular cylinders, and the inner walls of the first shell 10 and the second shell 20 extend inwardly along the circle There are at least two partition plates 30 arranged in the axial direction of the barrel. The partition plates 30 are annular plates. The inner wall of the partition plate 30 is closely matched with the outer wall of the muffler 50. 30 divides the space between the first housing 10, the second housing 20 and the muffler into at least one muffler cavity 40, the muffler cavity 40 is provided with a muffler material, and the partition plate 30 is also provided with a ring-shaped S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com