Detection device for detecting chamfers and end faces of rollers simultaneously

A detection device and roller technology, which is applied in the direction of measuring device, optical device, scattering characteristic measurement, etc., can solve the problem of chamfer detection defects on the roller, and can not detect the end face and chamfer of the roller well. Achieve the effect of no detection error and high detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below with reference to the accompanying drawings.

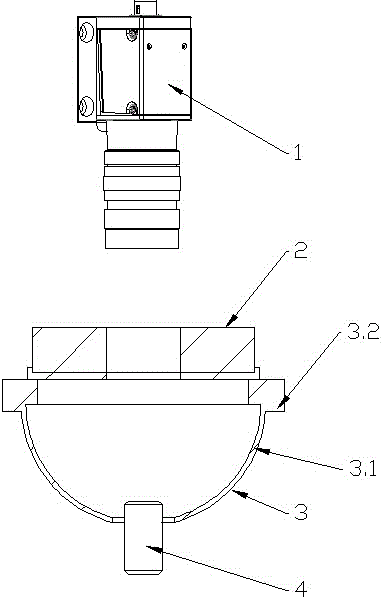

[0010] Such as figure 1 As shown, this embodiment provides a detection device for simultaneous detection of roller chamfering and end face, which includes a high-speed camera 1 and a ring light source 2, the ring light source 2 is located directly below the high-speed camera 1, and the ring light source 2 is directly below A spherical integrating light source 3 is provided. The spherical integrating light source 3 is composed of a hemisphere 3.1 and a large ring light source 3.2. The hemisphere 3.1 has a gap for the insertion of the roller 4, and the rollers 4 are arranged sequentially from bottom to top. , hemisphere 3.1, large ring light source 3.2, ring light source 2 and high-speed camera 1 coaxial line.

[0011] Detection of chamfering: the light source on the large ring light source 3.2 of the spherical integrating light source 3 is irradiated on the hemisphere 3....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com