A device and method for making needle point defects for cable testing

A needle point defect and cable test technology, applied in the direction of measuring devices, measuring electricity, measuring electrical variables, etc., can solve the problems of difficult control of needle point penetration depth, inaccurate test results, inconvenient production, etc., and achieve easy control of penetration depth, The effect of convenient and quick operation and high pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

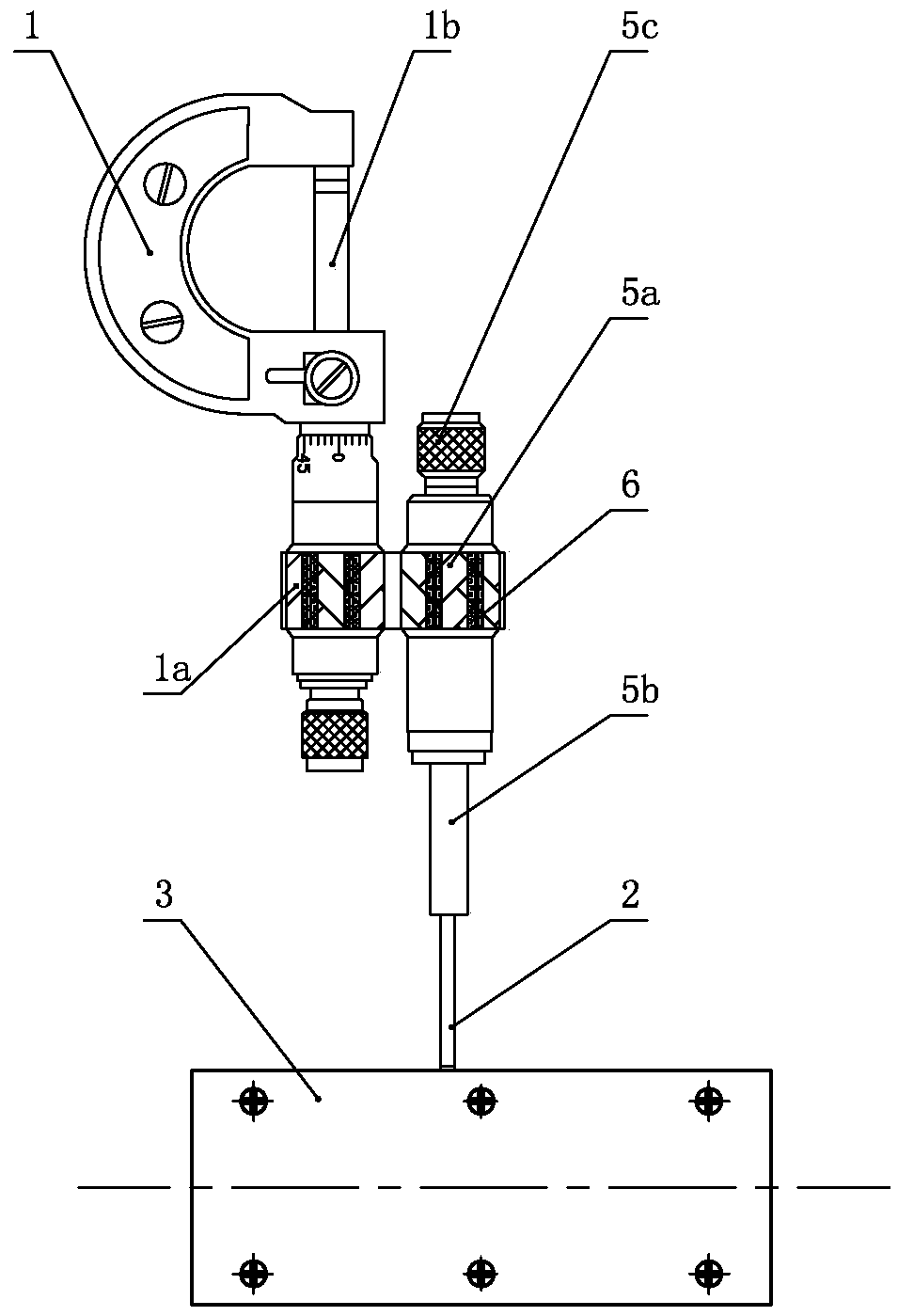

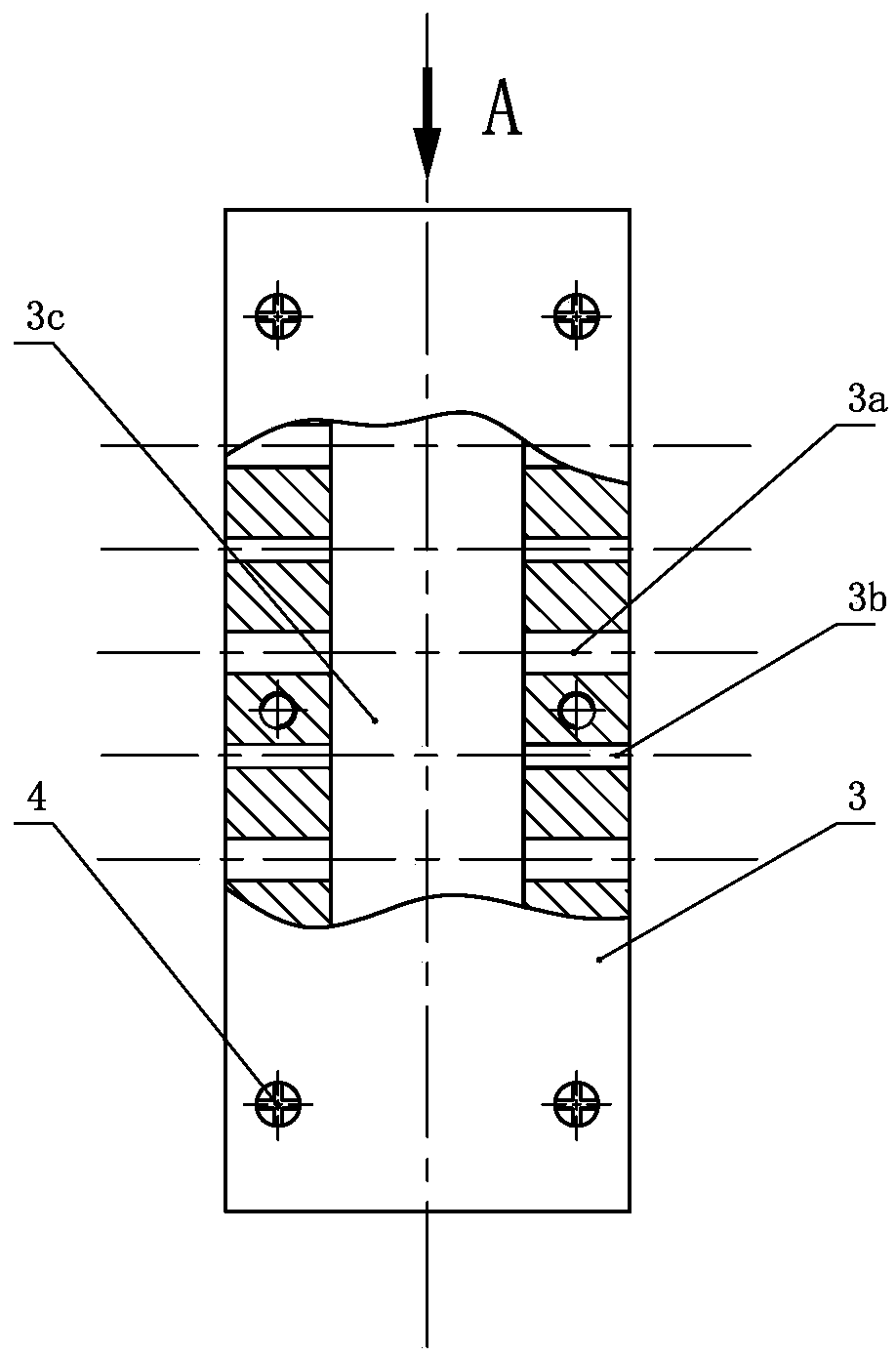

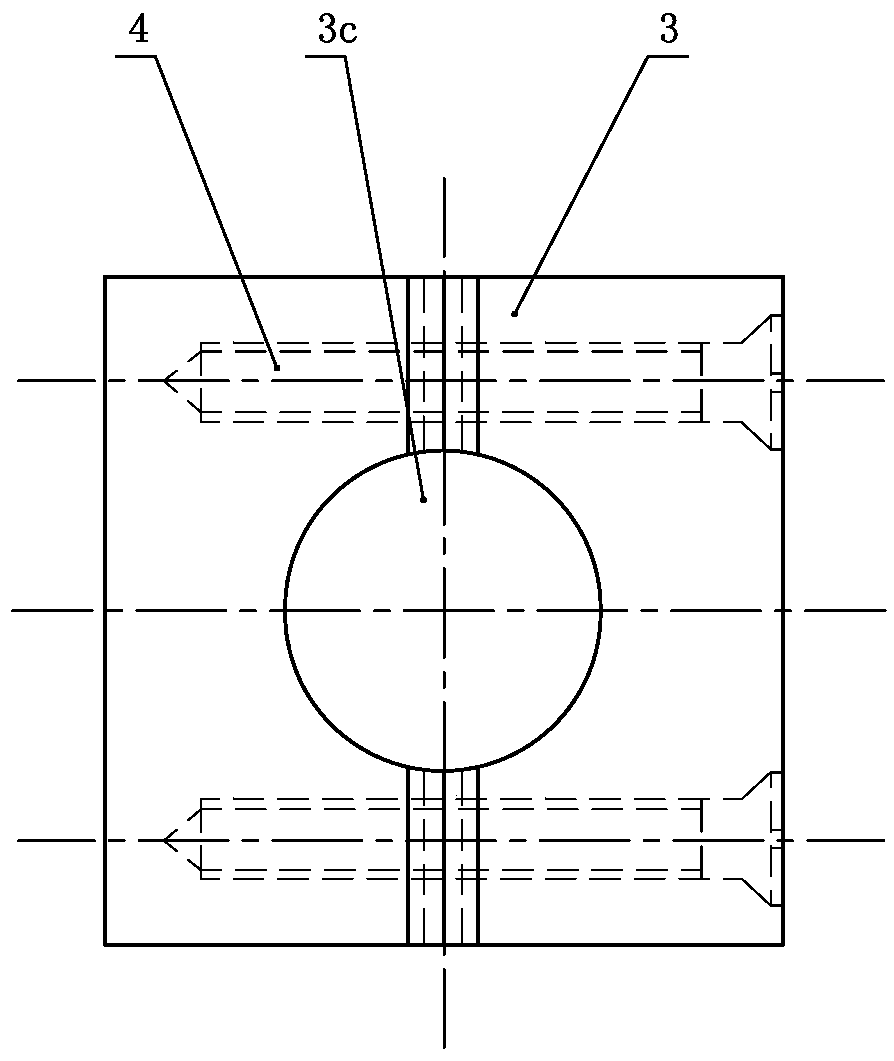

[0031] Such as Figure 1 to Figure 3 As shown in the device for making needle point defects for cable testing, the cable clamp 3 is in the shape of a square column, and the cable groove 3c for accommodating cables is axially opened along the centerline of the cable clamp 3 . The front and rear walls of the cable clamp 3 are provided with through holes, which are distributed linearly from left to right along the line of symmetry of the cable groove 3c, and the axes of the through holes are perpendicular to the axis of the cable groove 3c. The cable clamp 3 is divided into two modules along the distribution line of the through hole, that is, the symmetrical line of the cable groove 3c. The two mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com