A silicon solar cell with a thin film covering the front electrode and its manufacturing process

一种太阳能电池、制造工艺的技术,应用在太阳能电池领域,能够解决影响电池转换效率、易被腐蚀和氧化、接触面积减少等问题,达到提高电池转换效率、提高抗腐蚀性和抗氧化能力、降低串联电阻的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

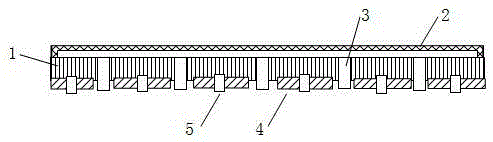

[0044] Embodiment 1: This embodiment provides a manufacturing process of thin-film covered MWT solar cells, which is completed through the following process steps:

[0045] 1) Punching: Use a laser to open a through hole 1 with a diameter of 200-300 microns at a predetermined position on the selected P-type silicon wafer. The so-called predetermined position is the position of the front electrode 3 of the solar cell, and the number of through holes is also the same as that of the front electrode 3. The number is the same.

[0046] 2) Texturing: Use HF and HNO3 to corrode the silicon wafer, forming a 1-3 micron egg structure on the surface of the silicon wafer.

[0047] 3) Diffusion: Phosphorus oxychloride and oxygen are used to diffuse phosphorus on the silicon wafer at high temperature. The diffusion resistance is 85 ohms to form a PN junction.

[0048] 4) Through hole back junction protection: A paraffin mask is printed on the back of the solar cell through hole to protect the throu...

Embodiment 2

[0056] Embodiment 2: This embodiment proposes a thin film covering MWT structure SE solar cell manufacturing process, including the following steps:

[0057] 1) Punching: Use a laser to open a through hole 1 with a diameter of 200-300 microns at a predetermined position on the selected P-type silicon wafer. The so-called predetermined position is the position of the front electrode 3 of the solar cell, and the number of through holes is also the same as that of the front electrode 3. The number is the same.

[0058] 2) Texturing: Use HF and HNO3 to corrode the silicon wafer, forming a 1-3 micron egg structure on the surface of the silicon wafer.

[0059] 3) Diffusion: Phosphorus oxychloride and oxygen are used to diffuse phosphorus on the silicon wafer at high temperature. The diffusion resistance is 85 ohms to form a PN junction.

[0060] 4) Through hole back junction protection: A paraffin mask is printed on the back of the solar cell through hole to protect the through hole and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com