Permanent-magnet claw-pole-type stepping motor rotor combined machine

A stepper motor and combined machine technology, which is applied in the manufacture of stator/rotor bodies, etc., can solve the problems of low efficiency, high labor intensity, and inability to effectively control the product yield rate, and achieve the effect of reducing production costs and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

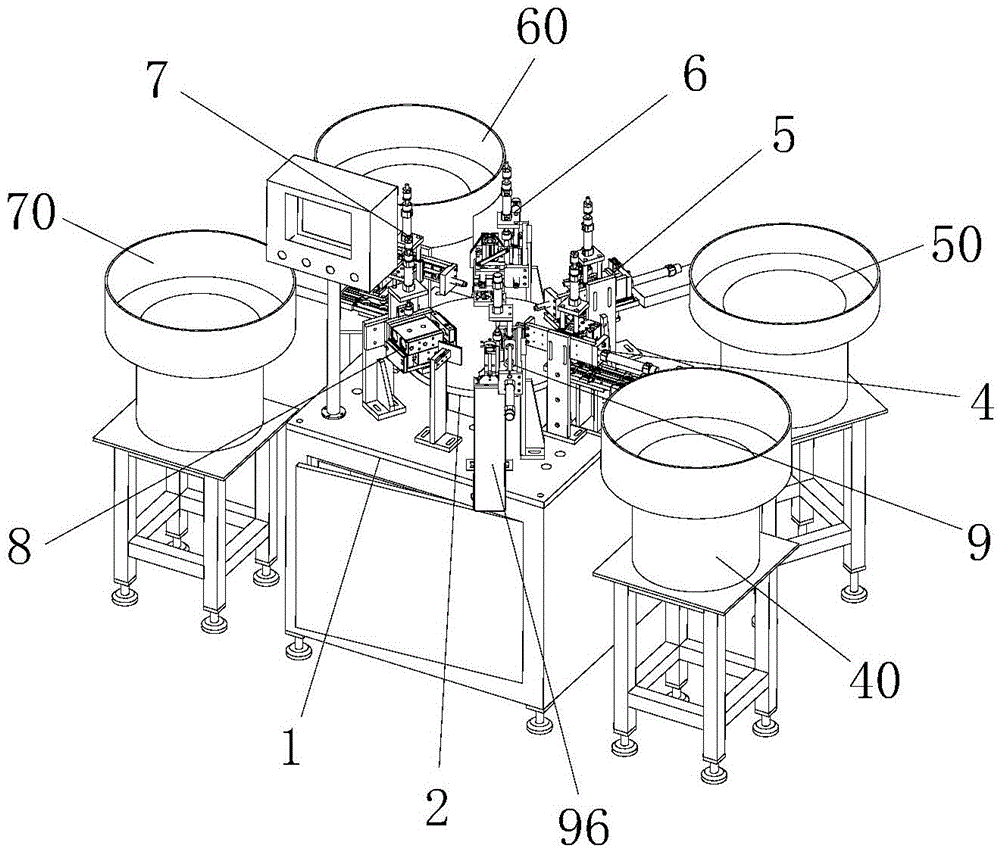

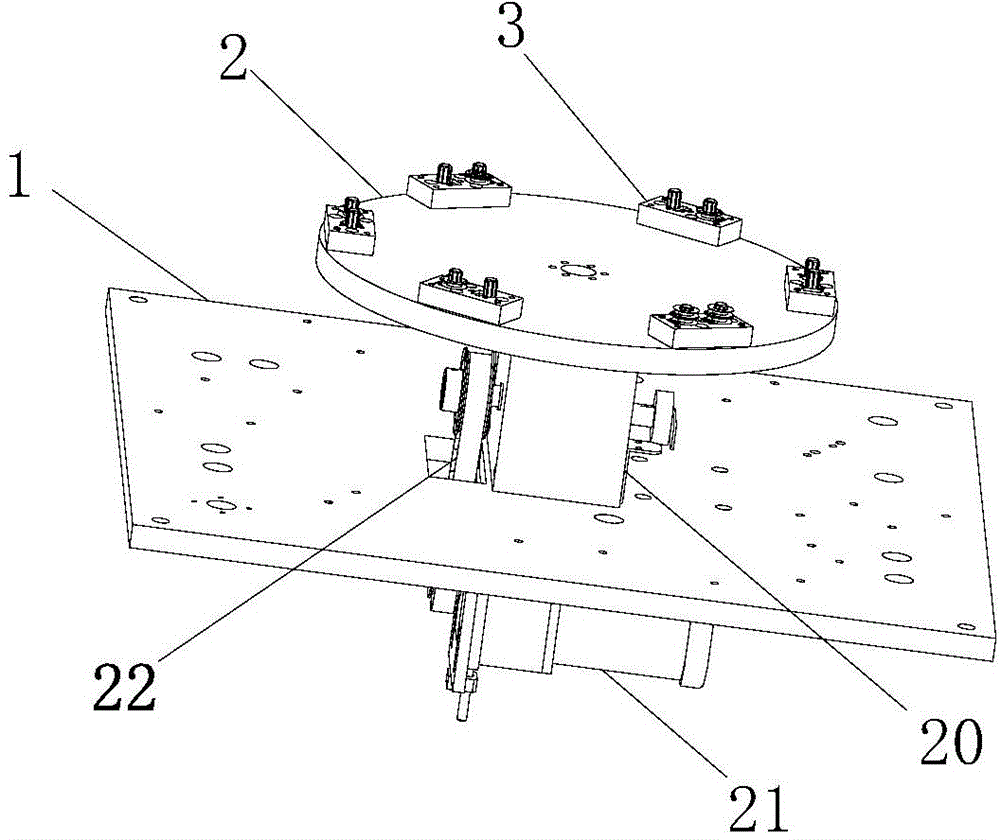

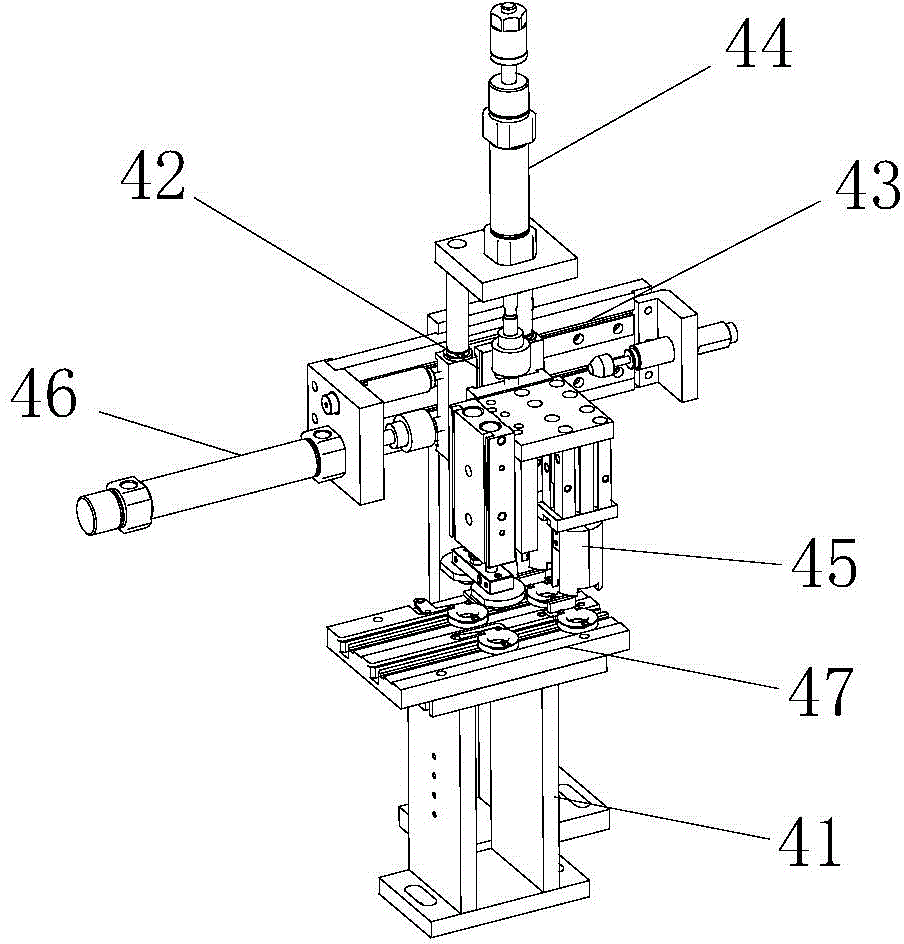

[0022] refer to Figure 1 to Figure 8 , a permanent magnet claw pole type stepping motor stator combination machine, comprising a machine base 1, a rotating disc 2 is installed on the machine base 1, a number of tooling positions 3 are installed on the rotating disc 2, the The rotating disc 2 is connected with a turntable power mechanism to drive it to rotate. The machine table 1 is equipped with a lower skeleton feeding mechanism 4 and a lower skeleton feeding mechanism 4 in sequence around the rotating disc 2 along the direction of rotation of the rotating disc 2. Magnetic plate feeding mechanism 5, upper magnetic plate feeding mechanism 6, upper skeleton feeding mechanism 7, combined skeleton mechanism 8 and automatic unloading mechanism 9, the lower skeleton feeding mechanism 4, lower magnetic plate feeding mechanism 5, upper magnetic plate feeding mechanism 6 and the upper frame feeding mechanism 7 are respectively connected with a lower frame vibrating plate 40, a lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com