Toy track capable of being freely spliced

A track and toy technology, which is applied in the track for toys, toys, entertainment, etc., can solve the problems of unfavorable player's manipulative ability and intelligence growth, increase the materials used in toy tracks, and the inability to assemble three-dimensional tracks, etc., to achieve a high degree of assembly freedom, Improve the scope of application and facilitate storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

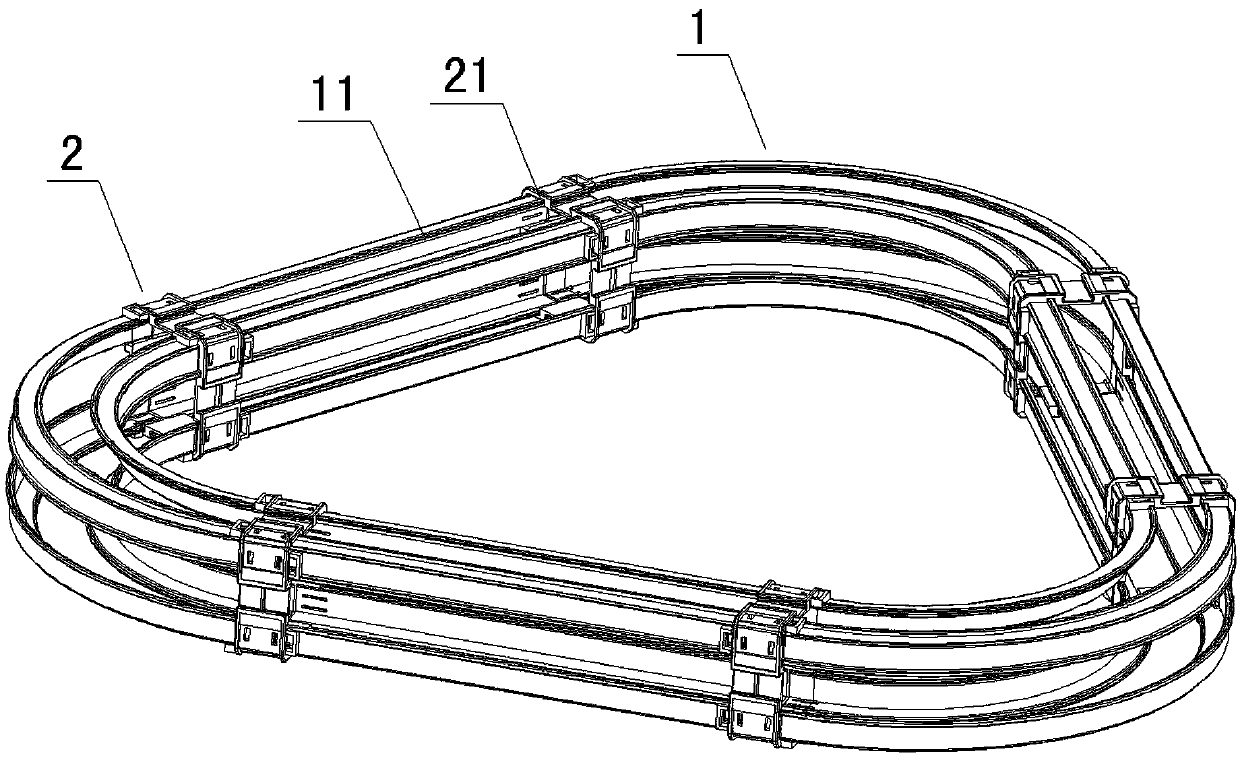

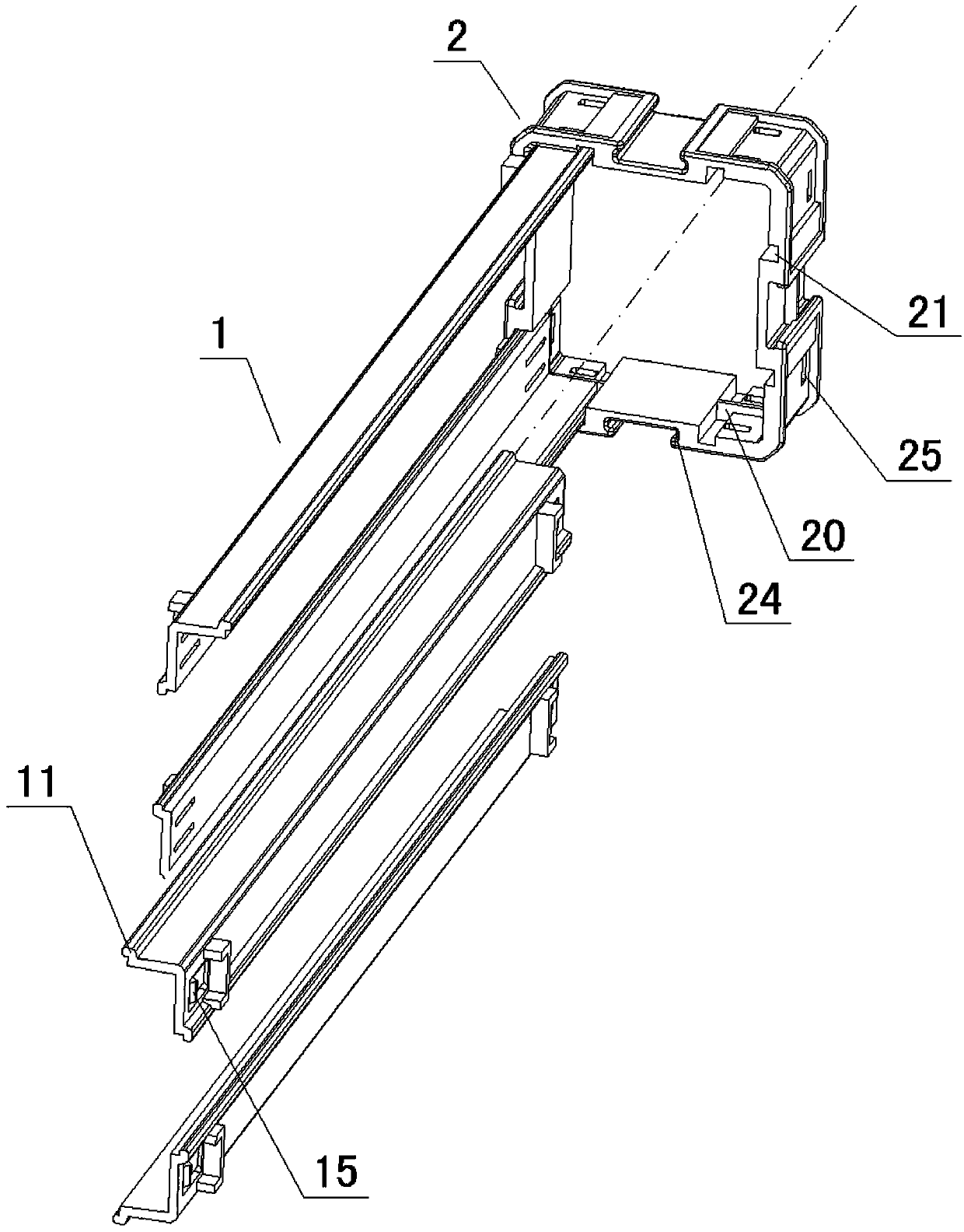

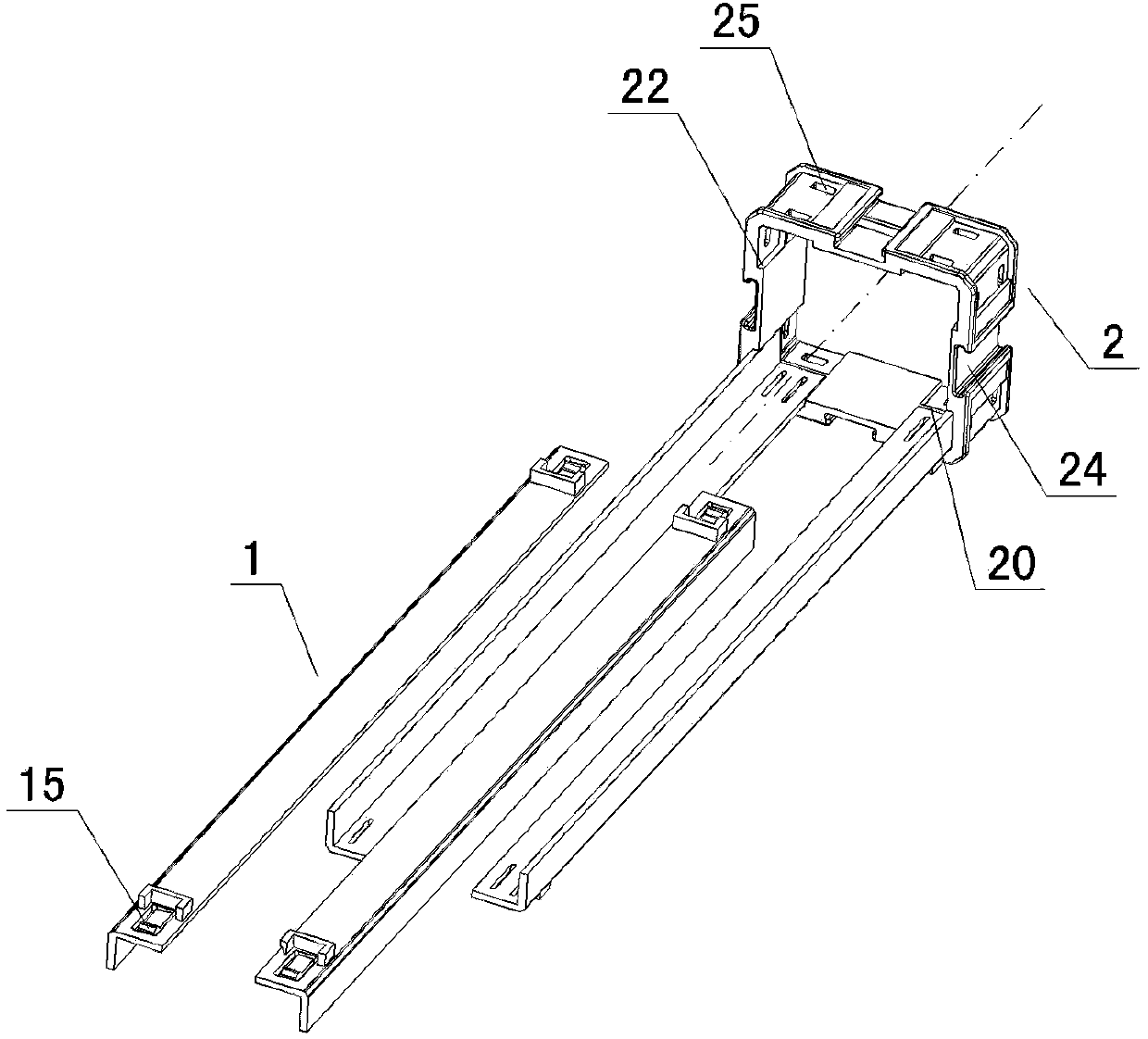

[0023] like Figure 1 to Figure 2 As shown, a freely assembled toy track described in this invention includes several guide rails and connectors, wherein each guide rail is two independent rails 1 on the left and right, and the connectors are frame-shaped parts 2. The frame-shaped part 2 is provided with connectors for connecting the ends of the rails 1 at the relative position of the inner frame edge, and the two ends of the left and right rails 1 are respectively connected to the connectors of the two frame-shaped parts 2 to form a The track body in the middle part of the track surface is exposed, and the left and right wheels of the toy car are just positioned on the left and right rails 1 so that the toy car can walk along the track, and the frame part 2 and the strip corresponding to the width can be selected according to the width of the toy car. Rail 1 connection, in order to widen the width of the rail, effectively improve the scope of application of the toy rail, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com