Monofilm die cutting method and die cutting machine

A single-layer film and die-cutting machine technology, which is applied in metal processing and other directions, can solve the problems of increasing the length of the production line, not sealing the cut marks, and increasing equipment costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029]The present invention will be described in further detail below in conjunction with the accompanying drawings.

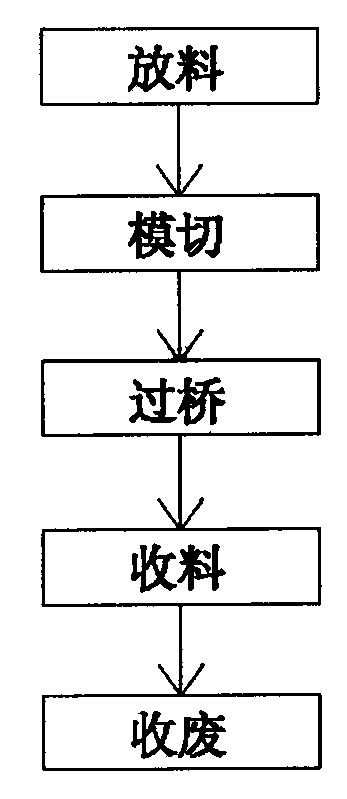

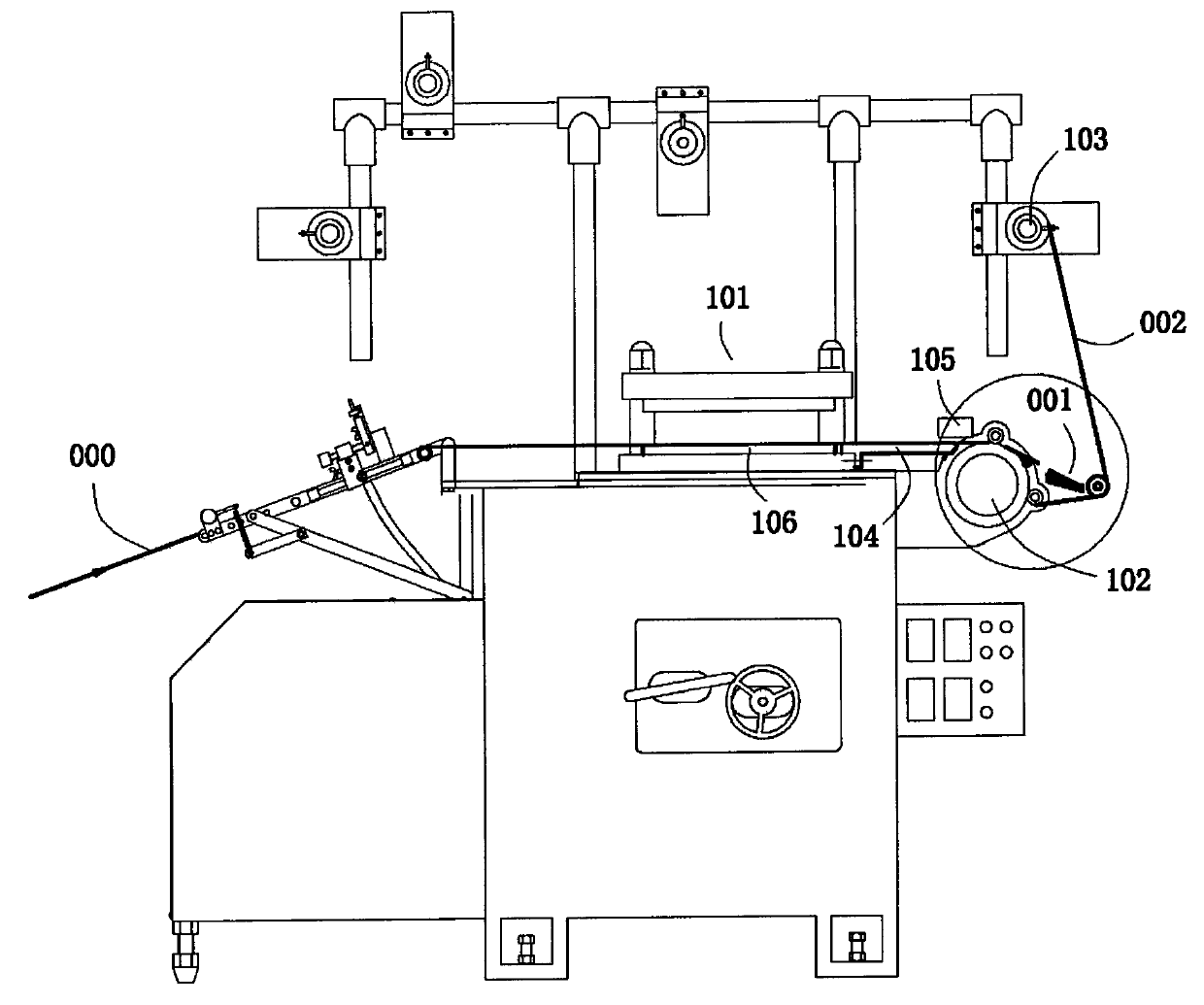

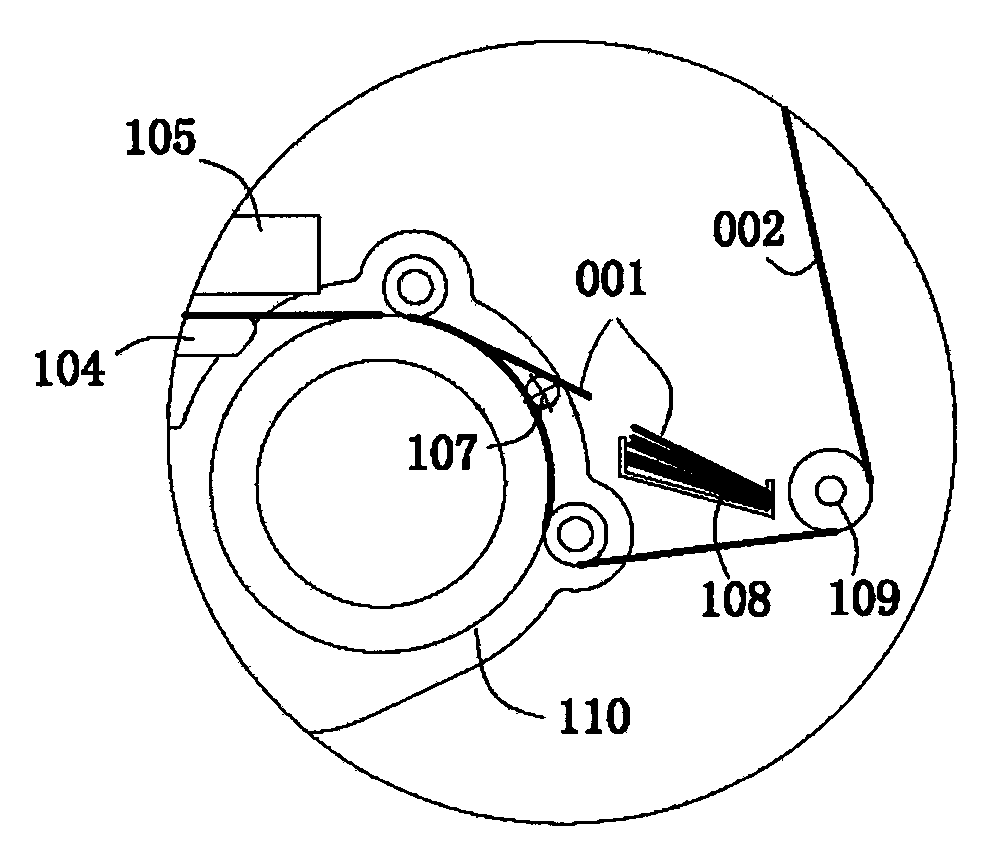

[0030] refer to figure 1 , the first embodiment of the present invention is a single-layer film die-cutting method, which is used in a flat die-cutting machine. The following steps: S10), feeding; S20), die cutting; S30), crossing the bridge; S40), receiving; S50), collecting waste; wherein, the die cutting described in the step S20) refers to cutting through; S30 The bridge described in the step) means that between the die-cutting device and the traction device, the finished product and the waste frame die-cut in the step S20) are guided to the traction device together by using a bridge board and an electrostatic plate, and the finished product after die-cutting It is separated from the frame, and the finished product and the frame are moved to the traction device synchronously by using a bridge plate and an electrostatic plate; S40) The receiving of the ste...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap