Winding apparatus

一种卷取装置、卷芯的技术,应用在卷绕条材、运输和包装、薄料处理等方向,能够解决难卷纸更换作业、未考虑正卷绕、反卷绕等问题,达到容易卷纸更换作业的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

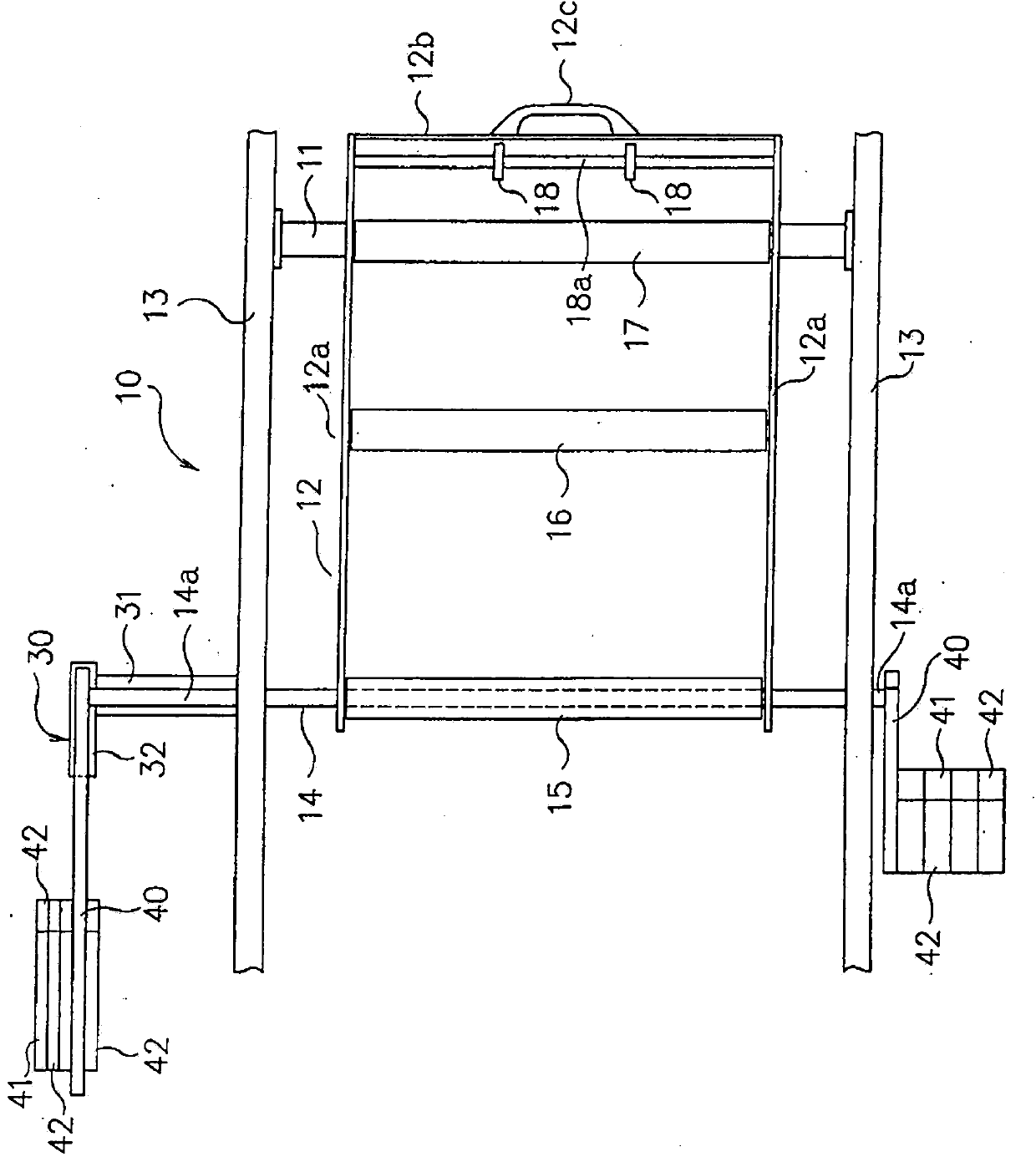

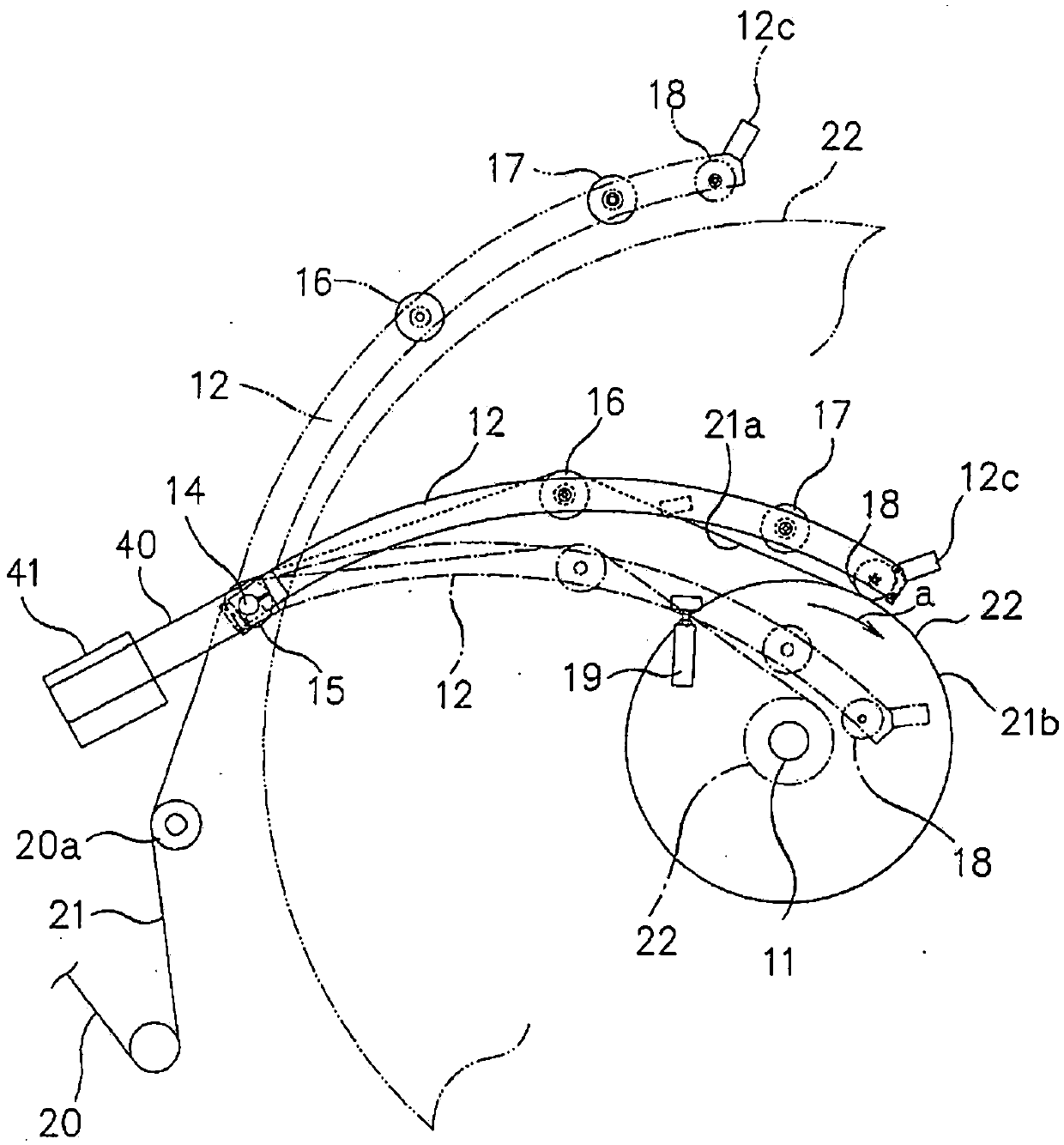

[0041] figure 2 It is a plan view of the winding device, and the winding device 10 includes a winding core 11 for winding paper, and an arm 12 rotatable toward the winding core 11 .

[0042] The winding core 11 is rotatably and detachably mounted between a pair of frames 13 that face each other in the paper width direction. Further, the winding core 11 is driven in forward rotation and reverse rotation by a drive source such as an electric motor not shown.

[0043] The base end of the arm 12 is rotatably supported between a pair of frames 13 in the direction that the front end approaches and separates from the winding core 11 by a rotation support such as a support shaft 14 , and the front end of the arm 12 approaches and separates from the winding core 11 .

[0044] In the arm 12, front ends of a pair of arm pieces 12a spaced apart in the paper width direction are connected by a connecting material 12b, and a handle 12c is provided on the connecting material 12b.

[0045] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com