Gas valve with proportional electromagnetic valve regulation and combustor air pressure feedback regulation functions

A technology of proportional solenoid valve and feedback adjustment, applied in valve details, valve operation/release devices, safety valves, etc., can solve problems such as large water temperature fluctuations, poor gas valve structure, and large hysteresis, and achieve stable water temperature and output Effect of stabilization, gas flow and pressure coordination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

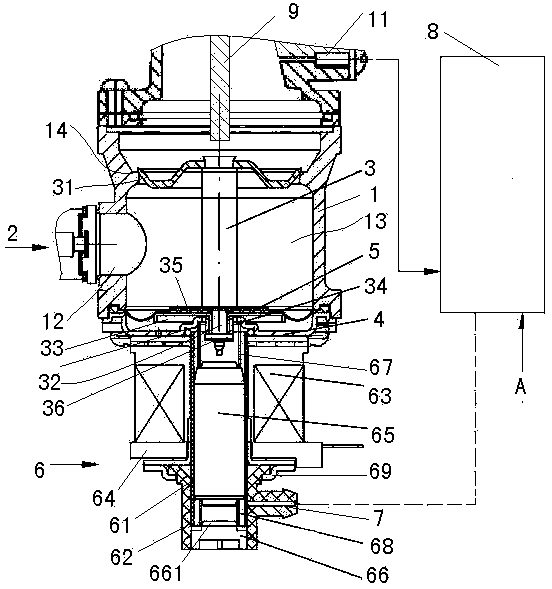

[0023] Embodiment 1: as figure 1As shown, a gas valve with proportional electromagnetic valve adjustment and combustion chamber air pressure feedback adjustment includes a proportional valve. The upper end of the valve body 1 of the proportional valve is provided with an output port 11, and the side of the valve body 1 is provided with an input port 12. The input port is connected to the The output port is connected through the buffer air cavity 13 in the middle of the valve body, and the input port 12 is connected with the electromagnetically controlled self-priming valve 2; there is an aluminum valve core 3 in the center of the buffer air cavity 13, and the upper end of the aluminum valve core 3 is connected to the valve disc 31, and the valve disc 31 Corresponding to the valve seat 14 on the upper side of the buffer air chamber 13, the valve seat 14 is directly processed on the valve body 1, and the valve flap 31 is made of a material that is soft and resistant to gas corros...

Embodiment 2

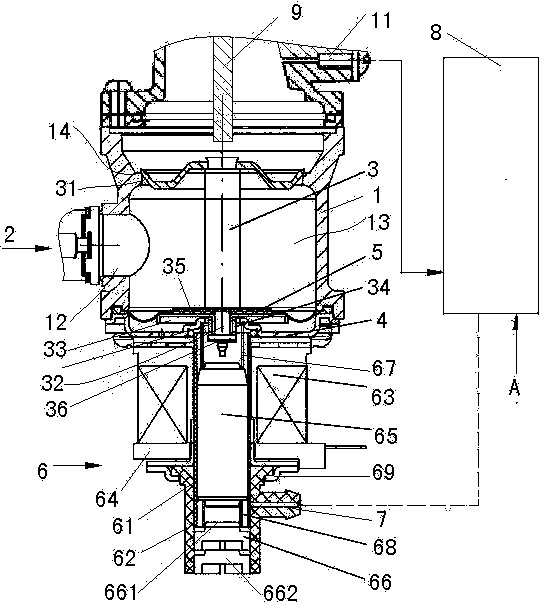

[0028] Embodiment 2: as figure 2 As shown, the lower end surface of the adjusting screw as the lower end cover 66 bears against the locking screw 662, and the rest of the structure is the same as that of embodiment 1, and the locking screw 662 is used to lock the adjusting screw, which is set by professionals during the factory debugging stage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com