Thick film heater

A thick-film heater and heating chip technology, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of occupying a large space, slow heating speed, and large size of the heater.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Further description will be given below in conjunction with the accompanying drawings and preferred embodiments of the present invention.

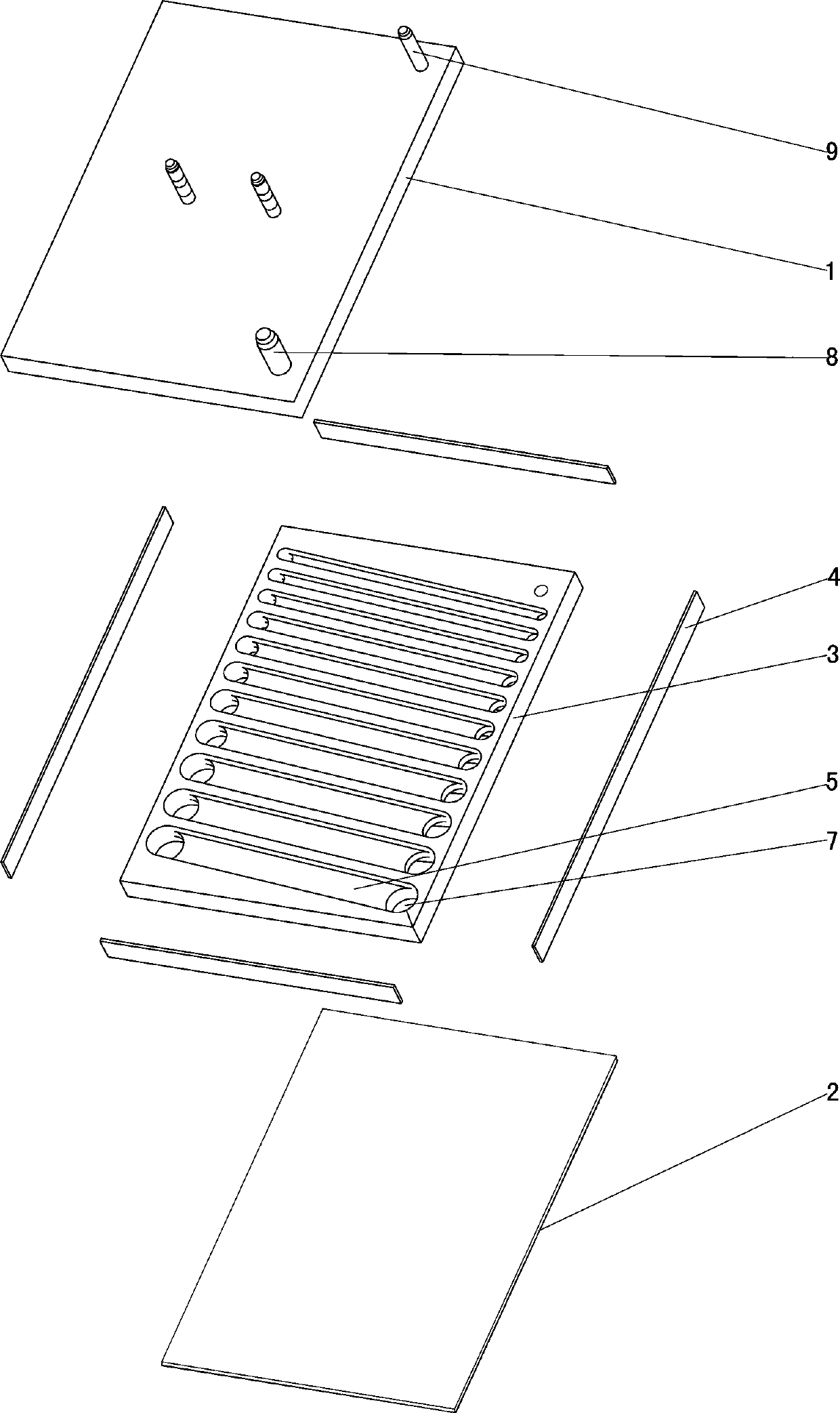

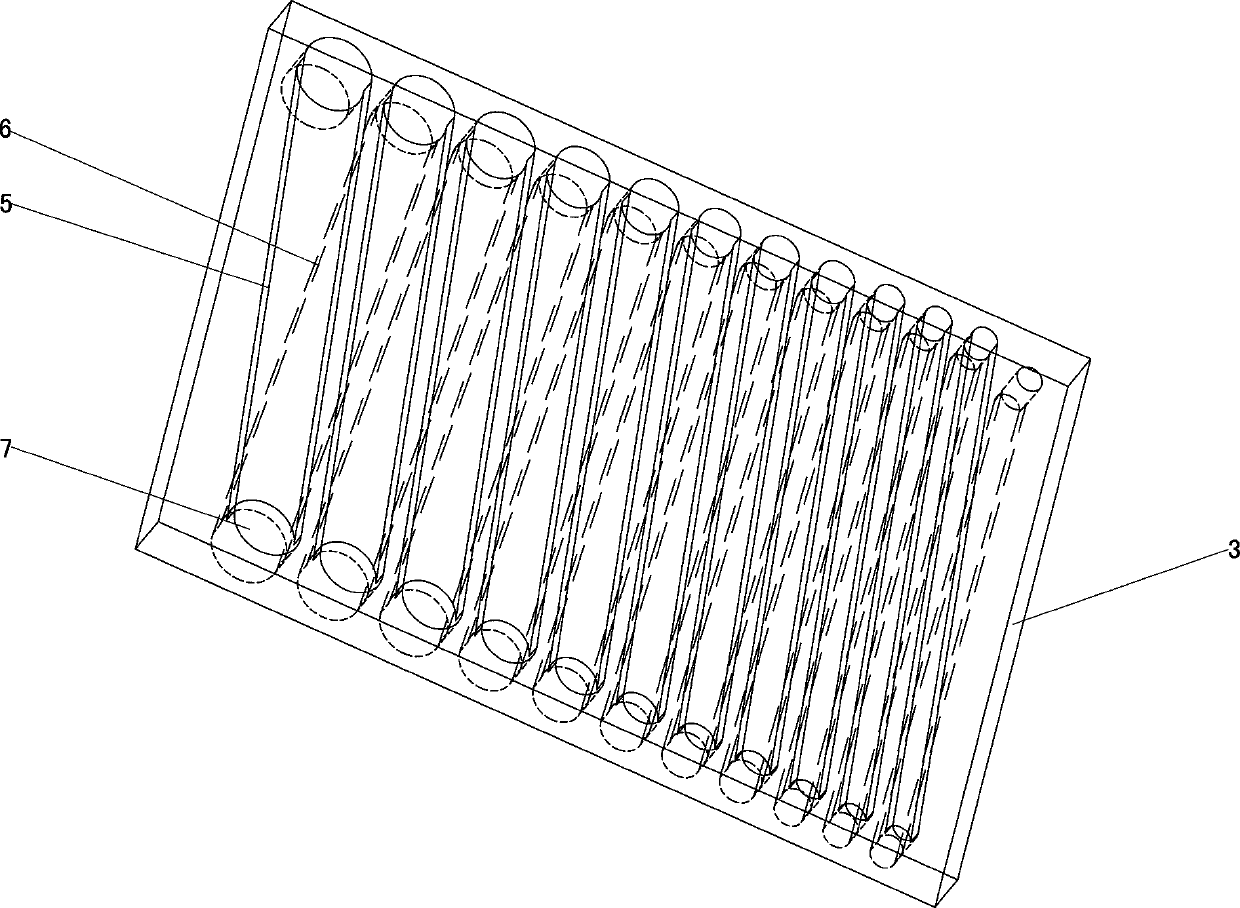

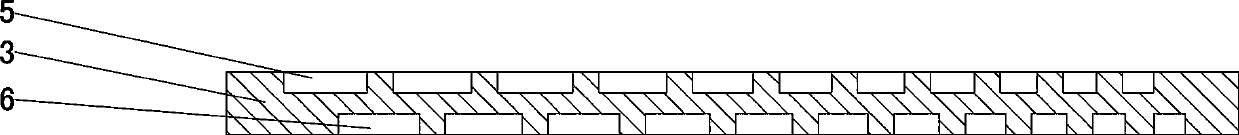

[0019] Such as Figure 1-Figure 4 As shown, this thick film heater includes a first heating sheet 1, a second heating sheet 2, an edible silica gel sheet 3 and four stainless steel sealing sheets 4, a second heating sheet 2, an edible silica gel sheet 3, and a first heating sheet 1 stacked together in turn, the first heating sheet 1 and the second heating sheet 2 clamp the edible silica gel sheet 3 in the middle, and four stainless steel sealing sheets 4 are respectively arranged on the four sides of the edible silica gel sheet 3; the first heating Both sheet 1 and the second heating sheet 2 include a stainless steel substrate 101, an insulating medium layer 102, a heating resistance layer 103, and a protective medium layer 104, and the insulating medium layer 102, the heating resistance layer 103, and the protective medium layer 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com