Lithium ion battery jelly roll production system and method

A technology for lithium-ion batteries and electric vehicles, which is applied in the manufacture of non-aqueous electrolyte batteries, electrolyte batteries, batteries, etc. It can solve the problems of high electromotive force of lithium-ion batteries, and achieve short-circuit and capacitance and leakage current deceleration effects. Long life and high efficiency The effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

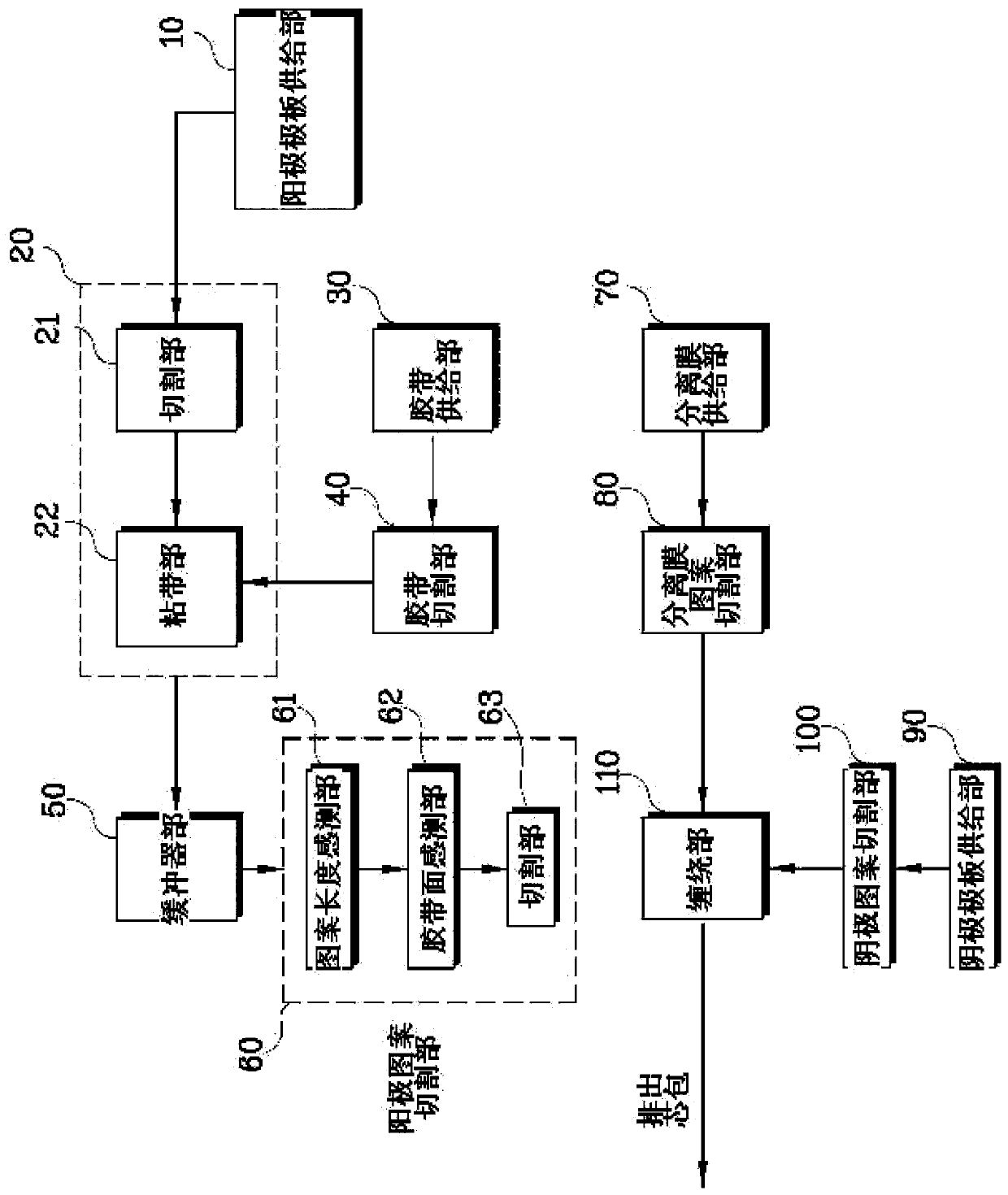

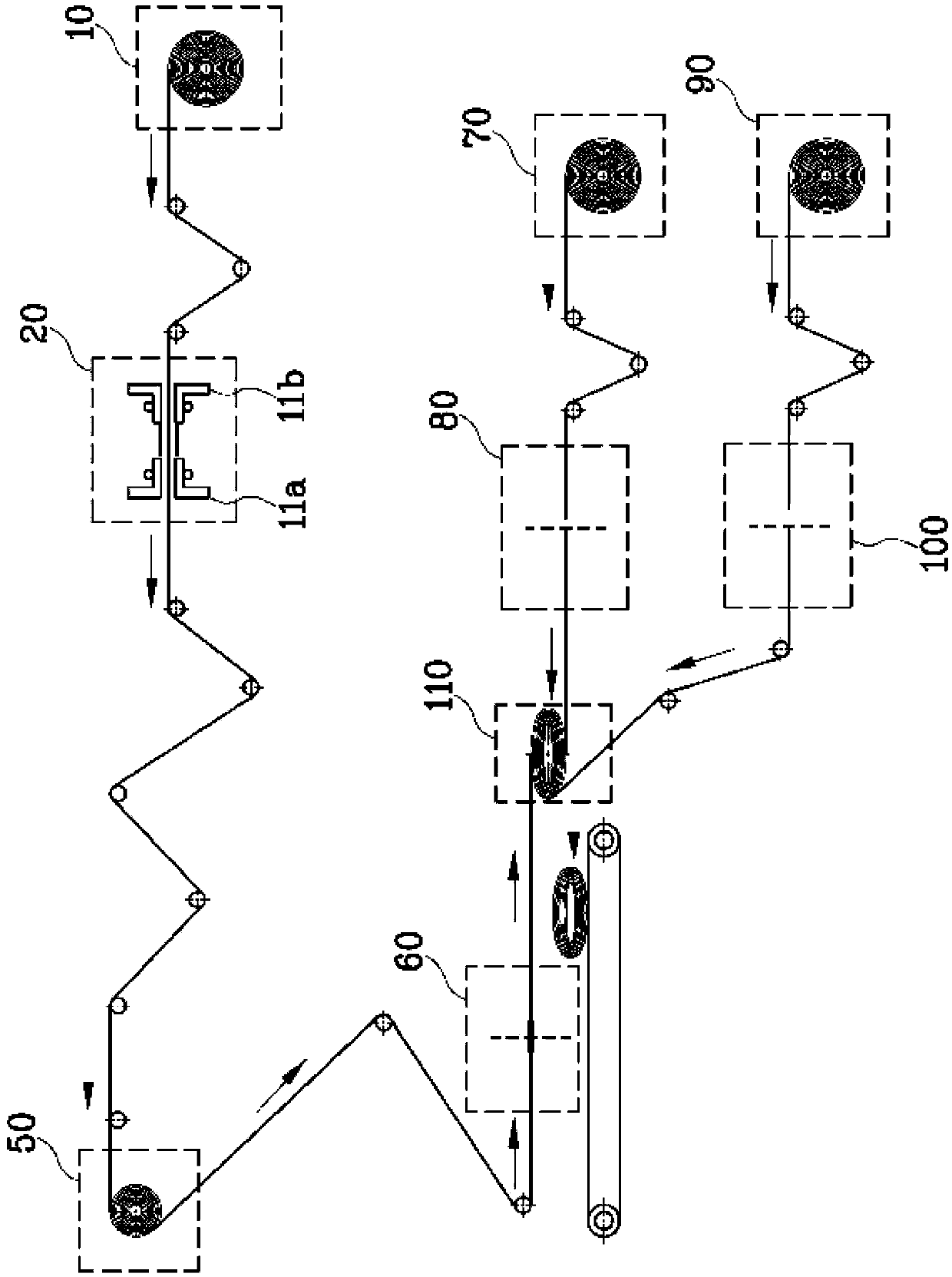

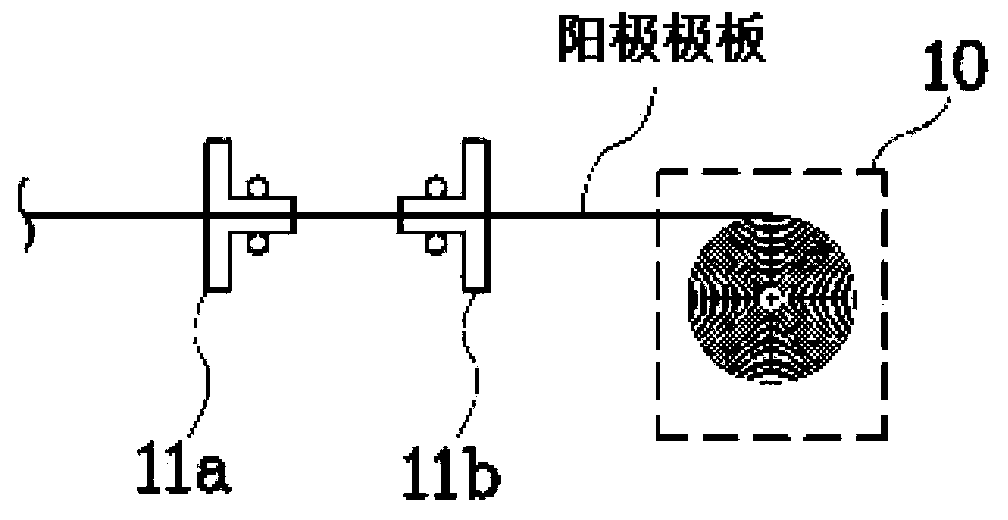

[0020] with reference to the attached Figure 1 to Figure 6 The illustrated embodiment describes the lithium-ion battery core pack production system for electric vehicles of the present invention as follows.

[0021] The composition of the present invention includes: an anode plate supply part 10, the anode plate supply part 10 accommodates and supplies the anode plate made; The anode plate supplied by the unit 10 is cut into the length of the pattern unit, and tape is carried out at the cutting position, thereby forming a cut surface of a pattern of the core package; the tape supply part 30, the tape supply part 30 is used to stick the pattern cut surface Adhesive tape is used for storage and storage, and the tape is supplied to the tape cutting part 40; the tape cutting part 40, the tape cutting part 40 receives the tape provided from the tape supply part 30, and the tape is cut into the bonding size of the pattern cutting surface, and the tape is supplied To the pattern cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com