Wiping mechanism

A pressing mechanism and wet wiping technology, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using tools, etc., can solve the problems of incomplete wiping, unsafe manual wiping, high labor intensity, etc. The effect of saving manufacturing costs and labor costs, convenient, fast and time-saving fixing, and easy to replace the clean cloth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

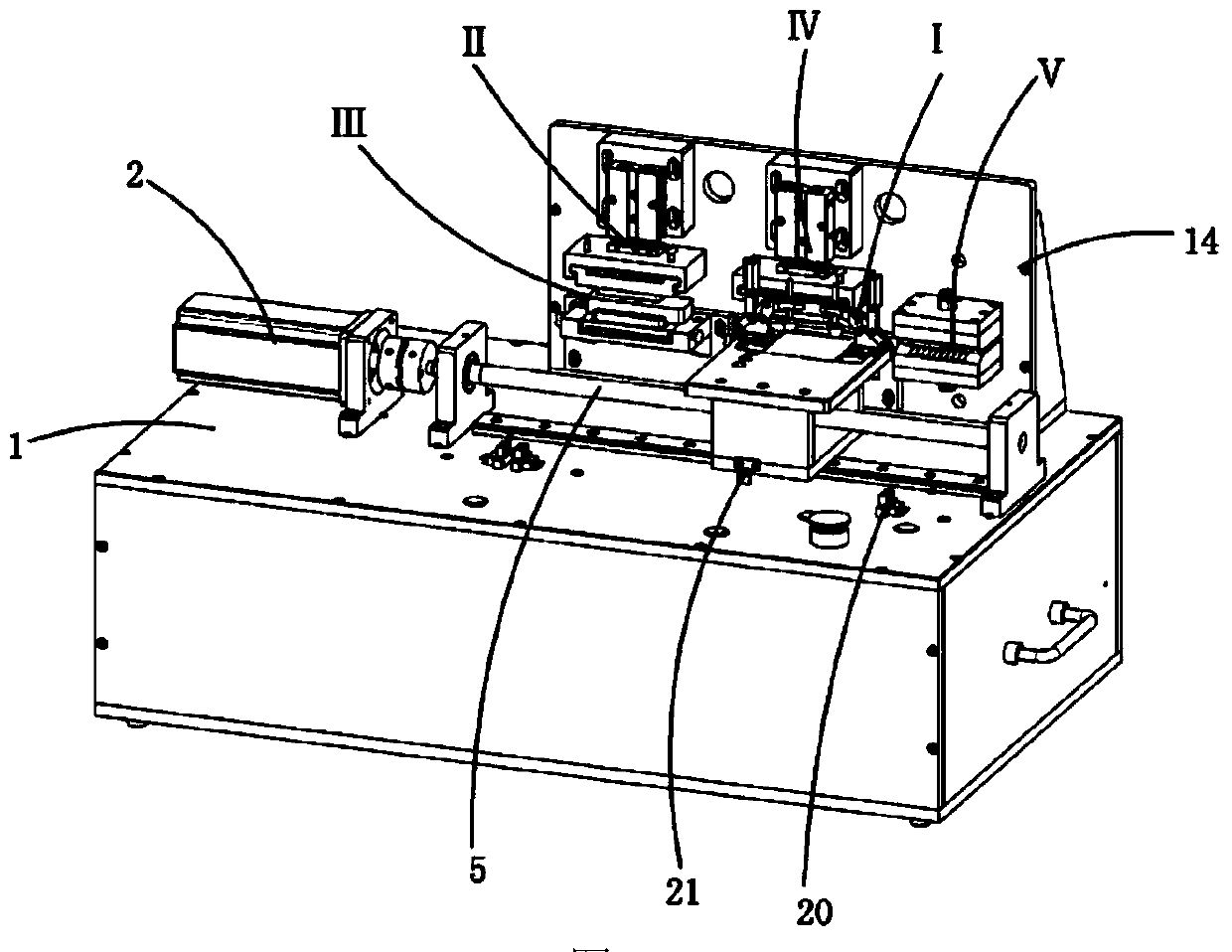

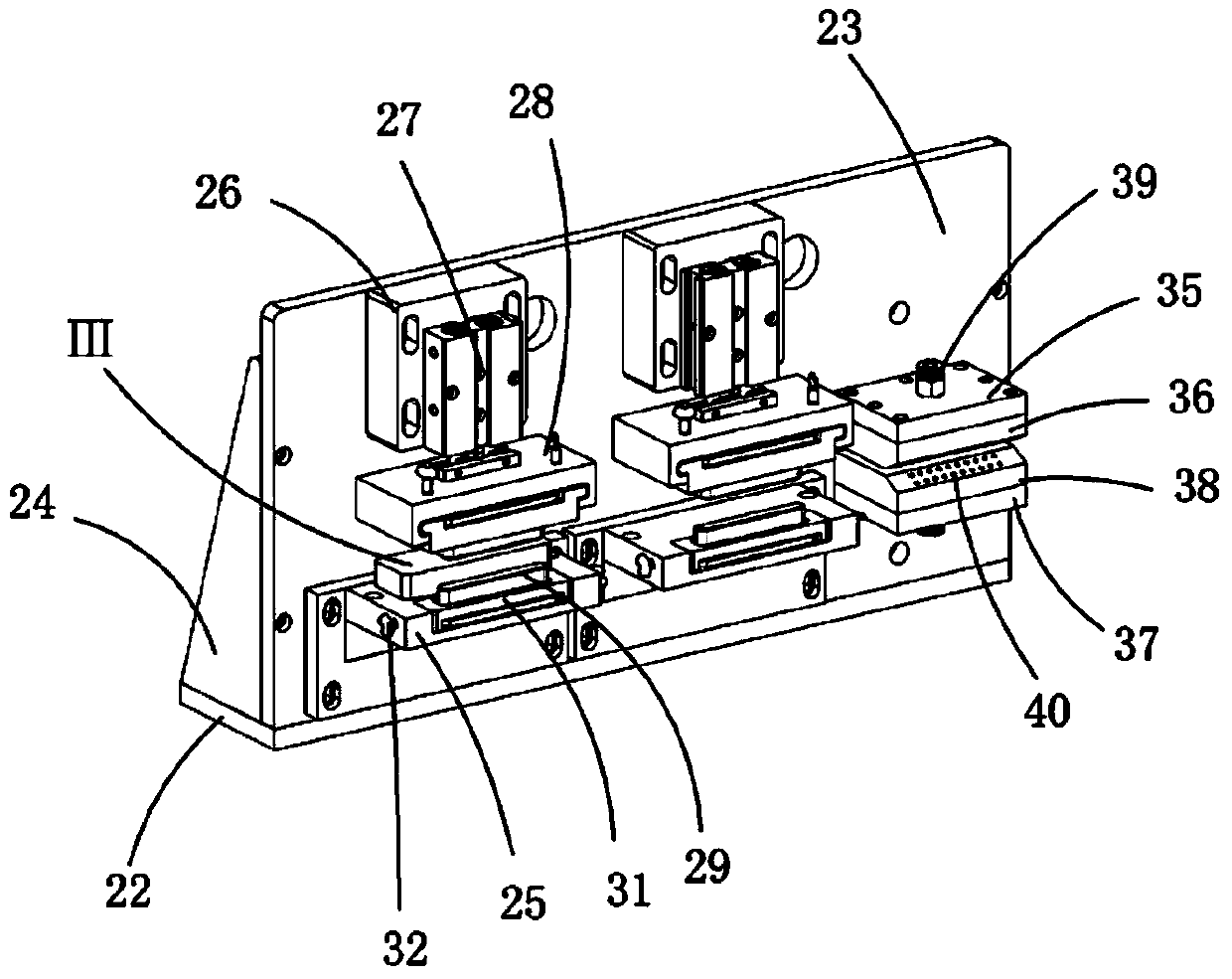

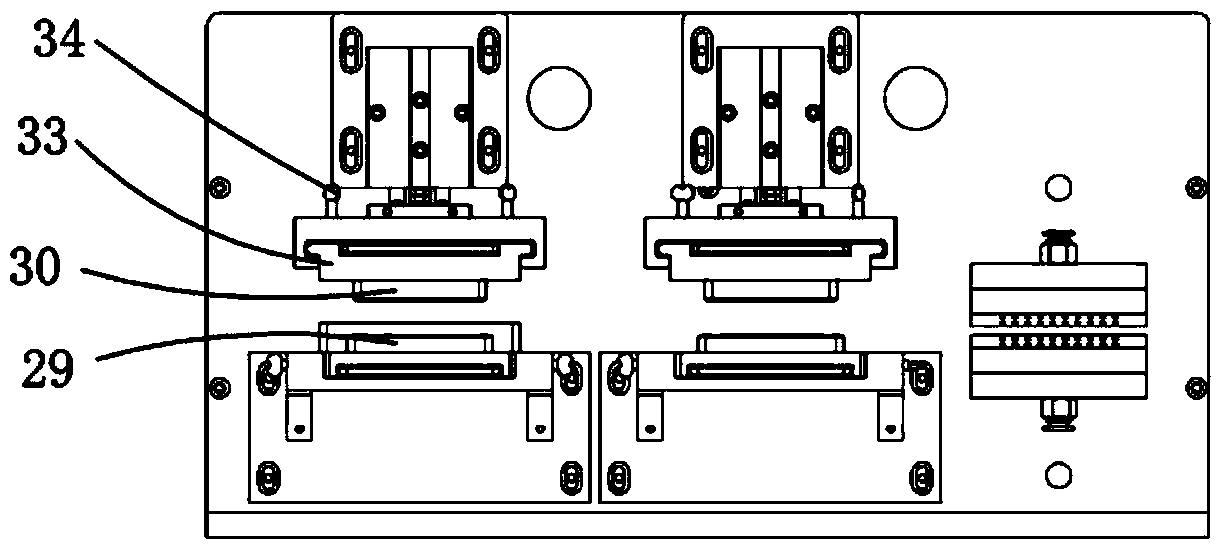

[0027] Examples, see attached Figure 1-7 , a wiping mechanism, which includes a workbench 1, a servo motor 2, a servo motor fixing seat 3, a coupling 4, a ball screw 5, a screw fixing seat 6, a connecting plate 7, a slide rail 8, a slider 9, Mobile plate 10, vertical plate 11, product carrier 12, electronic product 13, pressing mechanism I, support seat 14, wet wiping pressing mechanism II, alcohol dipping mechanism III, dry wiping pressing mechanism IV and blowing mechanism V, The servo motor is installed on the workbench through the servo motor fixing seat, the main shaft of the servo motor is connected to the ball screw through the coupling; the ball screw is connected with a connecting plate, and the two ends of the ball screw are fixed by the screw Seat support; slide rails are installed on the workbench, and sliders are installed on the slide rails, and the moving plate is installed on the sliders; the lower end of the connecting plate is connected to the moving plate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com