Sanitary napkin cutting machine

A technology of slitting machine and toilet paper, which is applied in the direction of metal processing, etc., which can solve the problems that the roll paper to be slit is prone to offset, affects the quality of the incision, and the volume of the slitting machine is large, so as to improve the slitting efficiency and the quality of the incision , stable and reliable rotation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

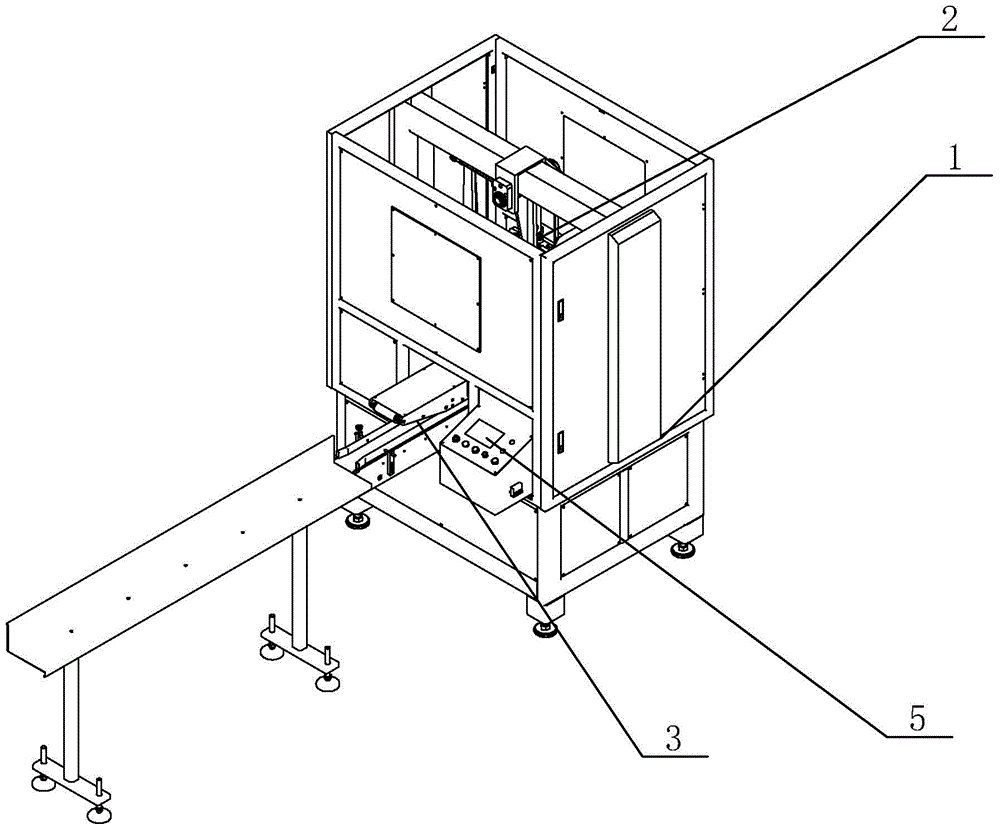

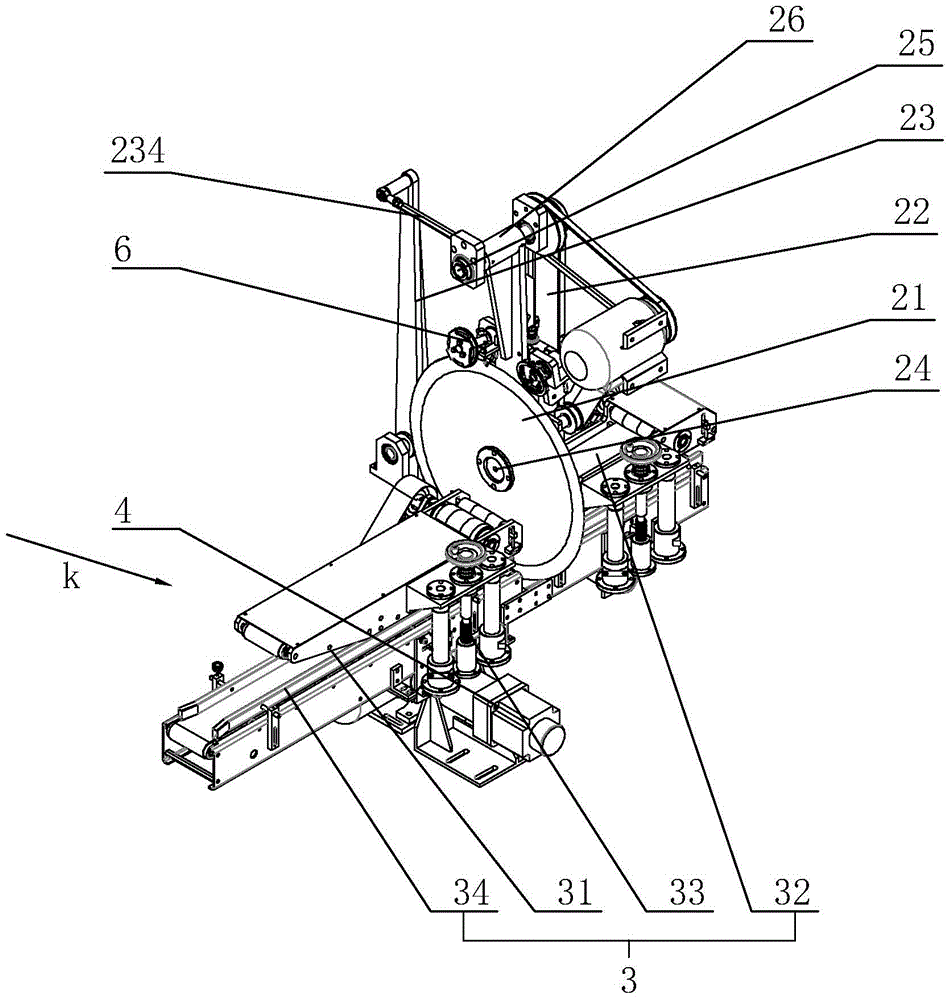

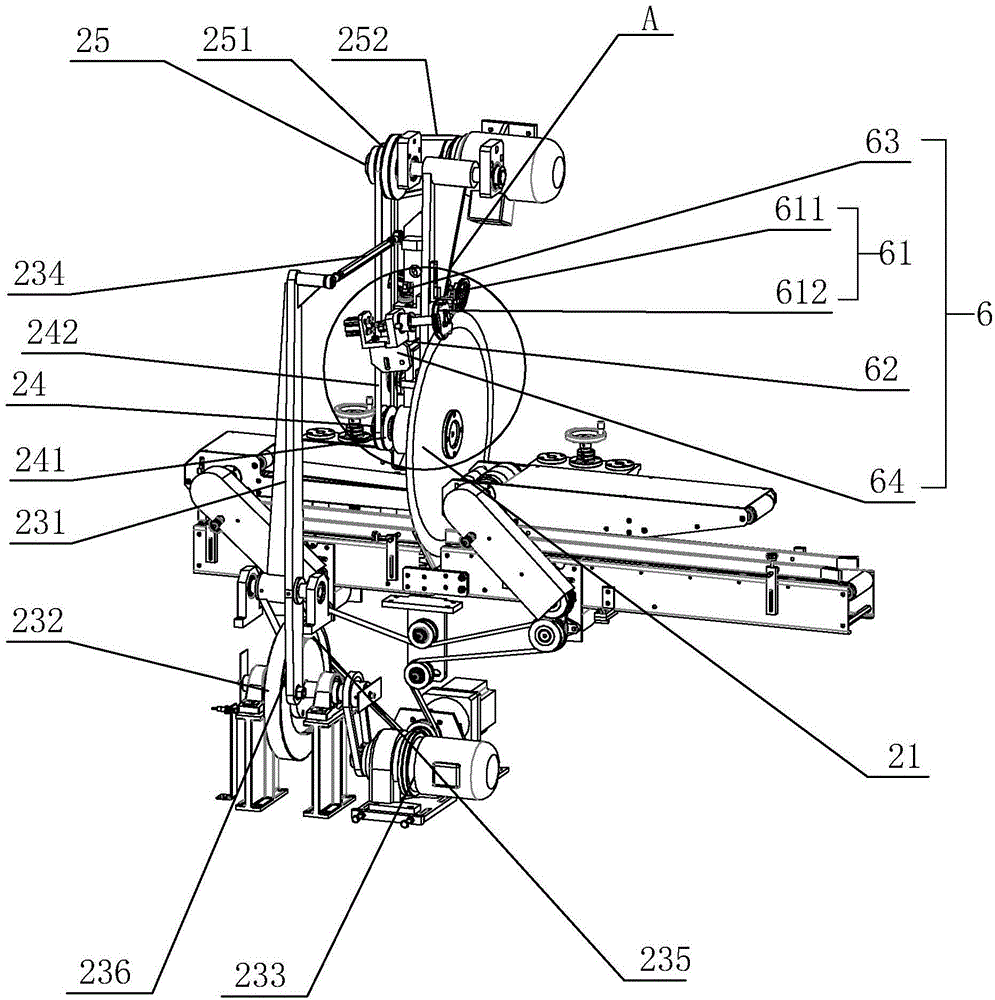

[0033] refer to Figure 1 to Figure 6 The embodiment of a sanitary napkin slitting machine of the present invention will be further described.

[0034] A sanitary paper towel cutting machine, comprising a frame 1, a paper cutting mechanism 2, a conveying mechanism 3 for conveying sanitary paper towels, a driving mechanism 4 for driving the conveying mechanism to convey sanitary paper towels, a paper cutting mechanism 2 for controlling, and a conveying mechanism 3 , the control device 5 for the operation of the driving mechanism 4, the paper cutting mechanism 2 includes a rotary cutter 21 for cutting sanitary paper towels, a first motor 22 for driving the rotary cutter to rotate, and a swing device for driving the rotary cutter 21 to swing back and forth 23; the conveying mechanism 3 includes an input assembly 31 and an output assembly 32; the rotary cutter 21 is placed between the input assembly 31 and the output assembly 32, in order to facilitate the sanitary tissue on the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com