Regenerated rubber powder production device

A production device, a technology for reclaimed rubber, applied in the direction of filter screen, grille, solid separation, etc., can solve the problems of short service life of elastic support, affecting the quality of recycled rubber, and difficult to completely remove iron powder, etc., to achieve extended service life, The effect of high screening efficiency and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

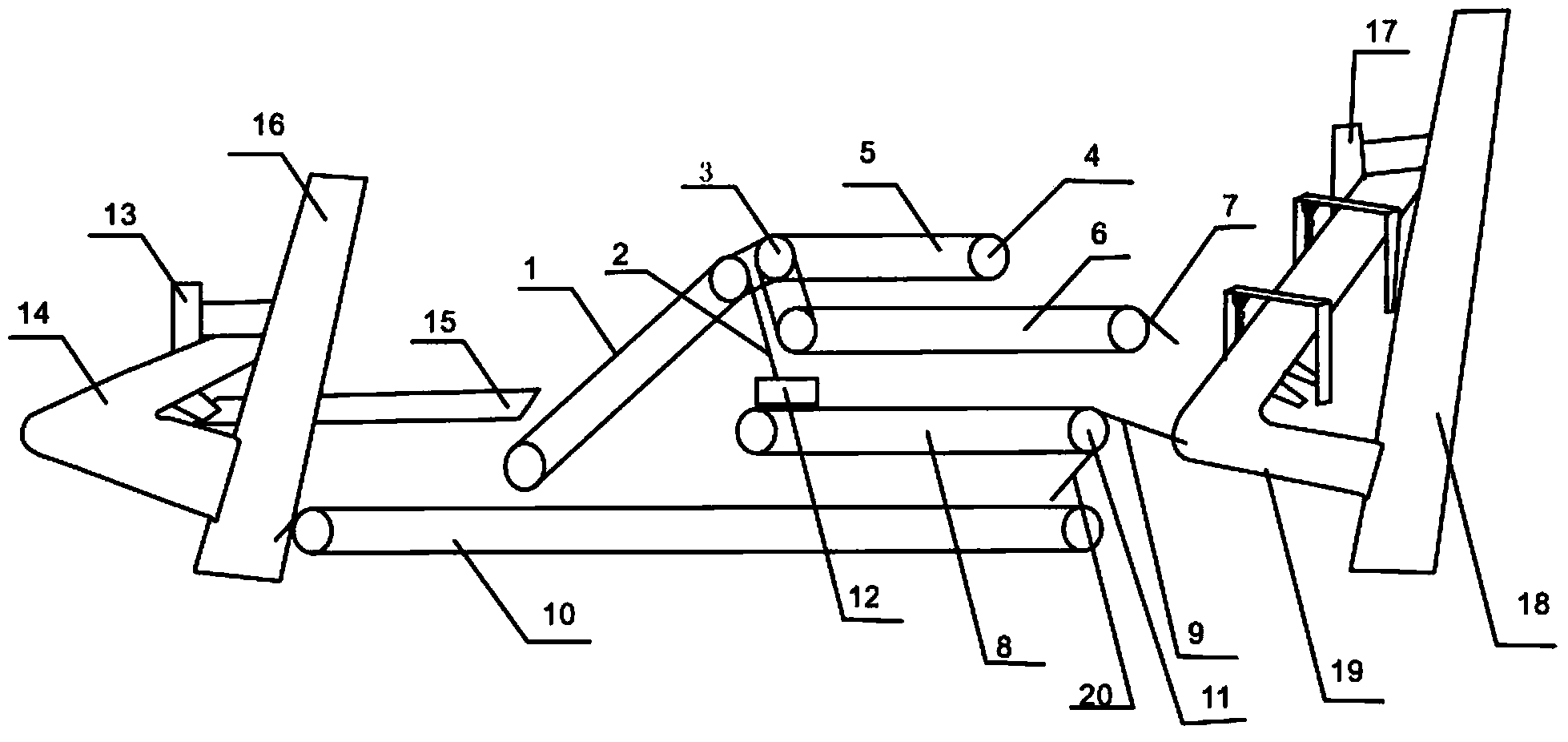

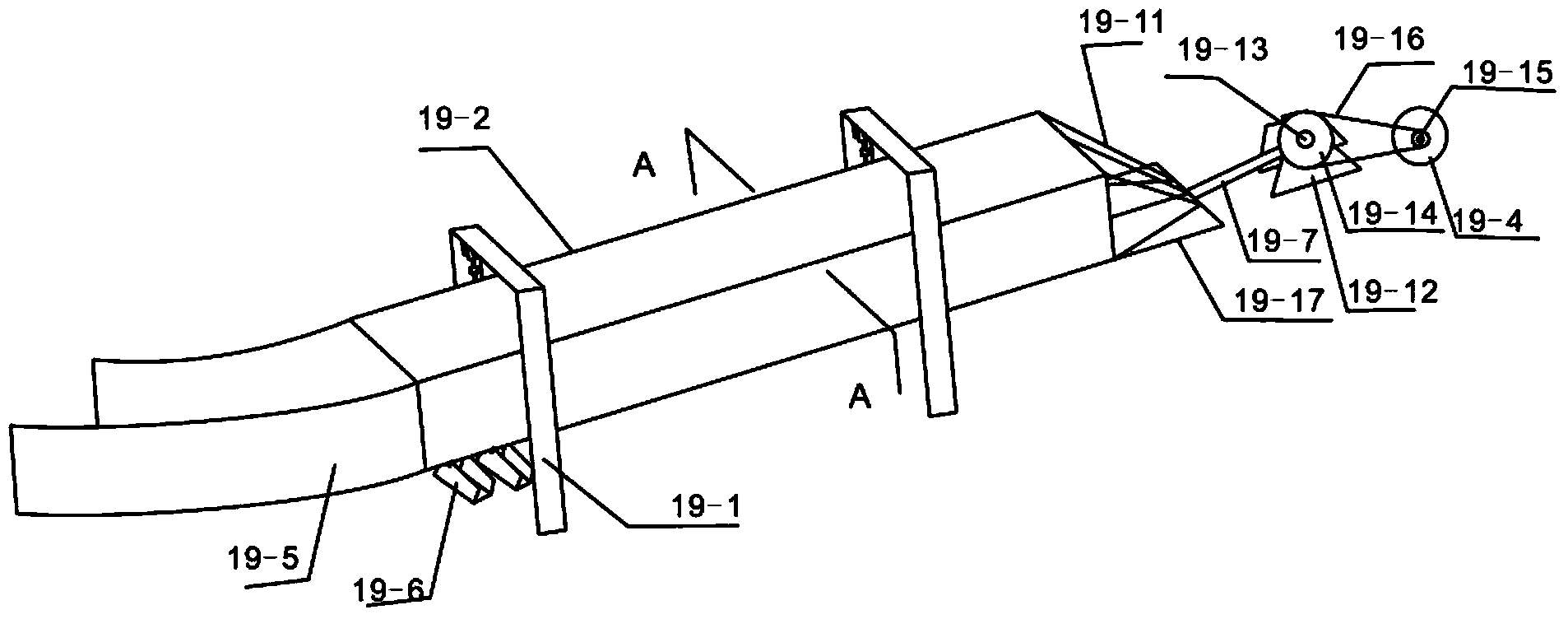

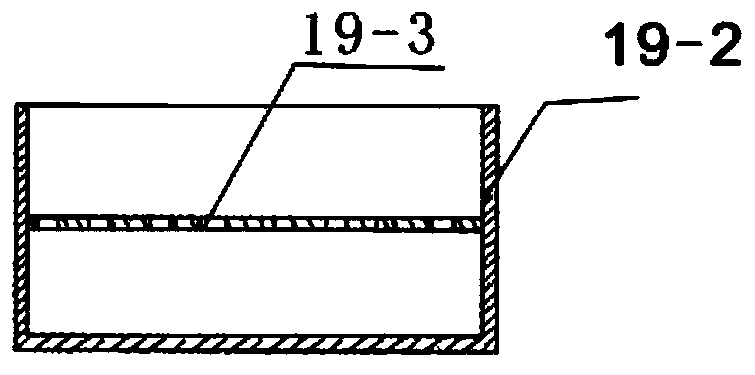

[0022] Example 1, such as Figure 1-5 As shown: the regenerated rubber powder production device of the present invention is composed of a mixture conveyor belt 1, a rubber particle discharge hopper 2, a first full magnetic drum 3, a driven drum 4, a steel wire separation conveyor belt 5, a steel wire recovery conveyor belt 6, and a steel wire discharge conveyor belt. Hopper 7, rubber particle conveying belt 8, rubber discharge hopper 9, circulating conveying belt 10, second full magnetic drum 11, baffle plate 12, rubber coarse crushing machine 13, first vibrating screen 14, first conveying belt 15, recycling Conveyor belt 16, rubber rubber pulverizer 17, the second conveyor belt 18, the second vibrating screen 19 and other components.

[0023] The structures of the rubber coarse pulverizer 13 and the rubber powder pulverizer 17 are prior art, and their structures are not described in detail here. First and second vibrating screens 14, 19 are respectively arranged below the ru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com