Automatic coffee filling machine

A filling machine, automatic technology, applied in the direction of packaging, transportation and packaging, packaging item types, etc., can solve the problems of shelf life, coffee capsules, coffee powder can not be compressed, etc., to achieve stable transmission process and ensure sealing Effect, Rate Average Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

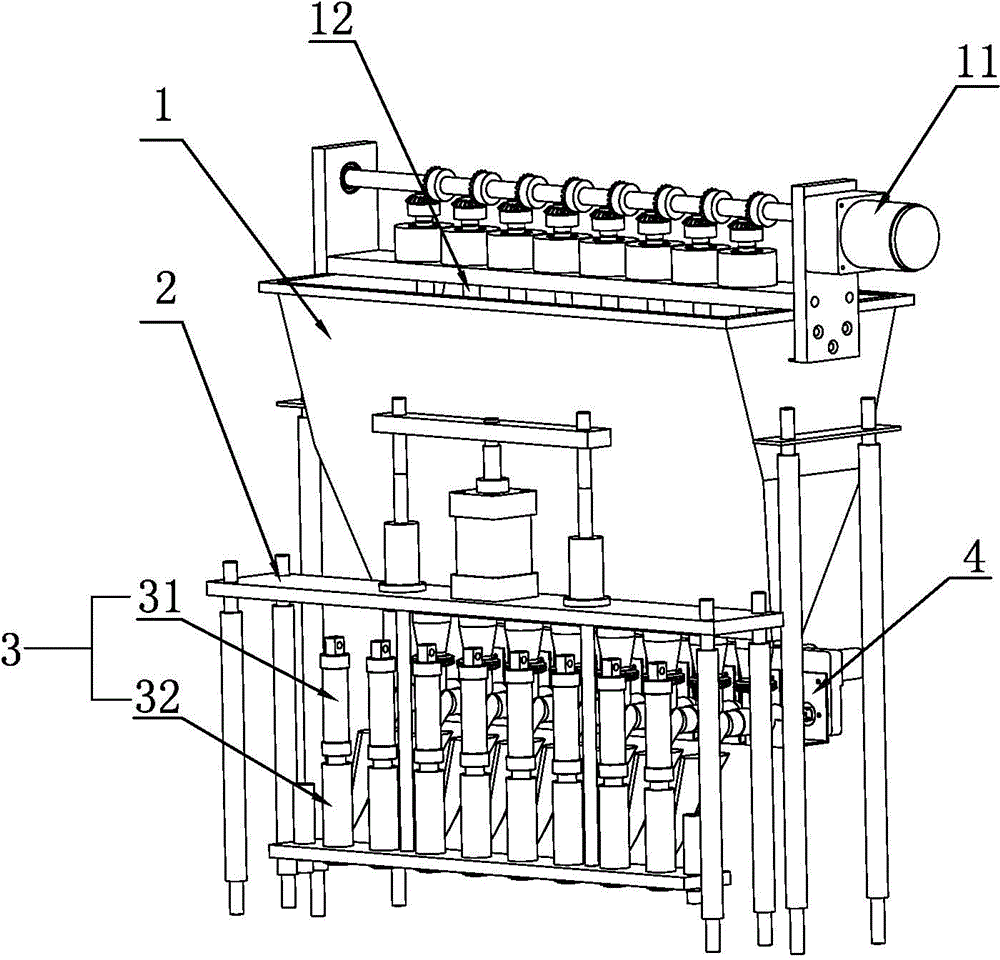

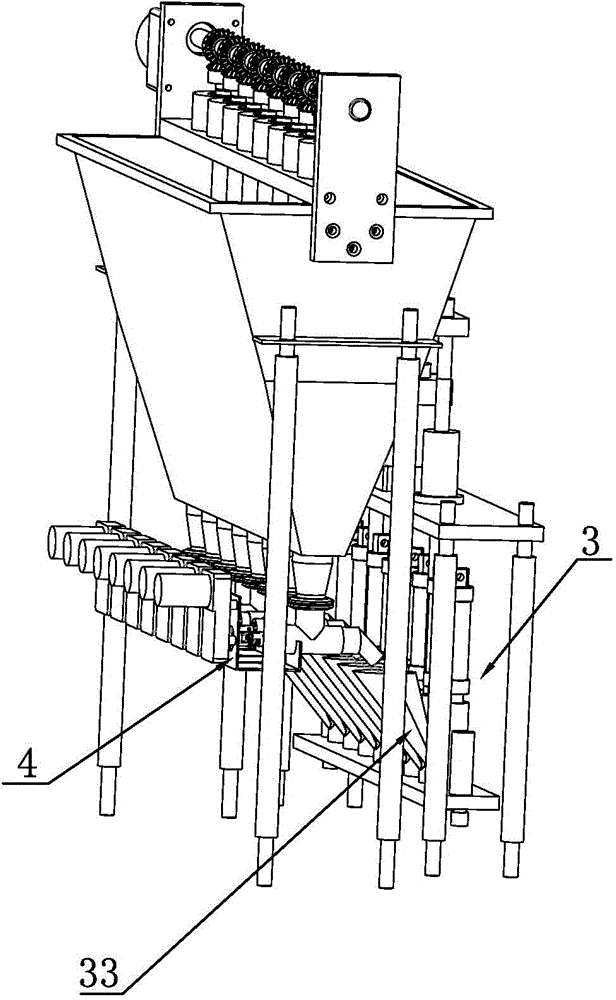

[0030] The automatic coffee filling machine of the present invention will be further described below in conjunction with the accompanying drawings of the specification.

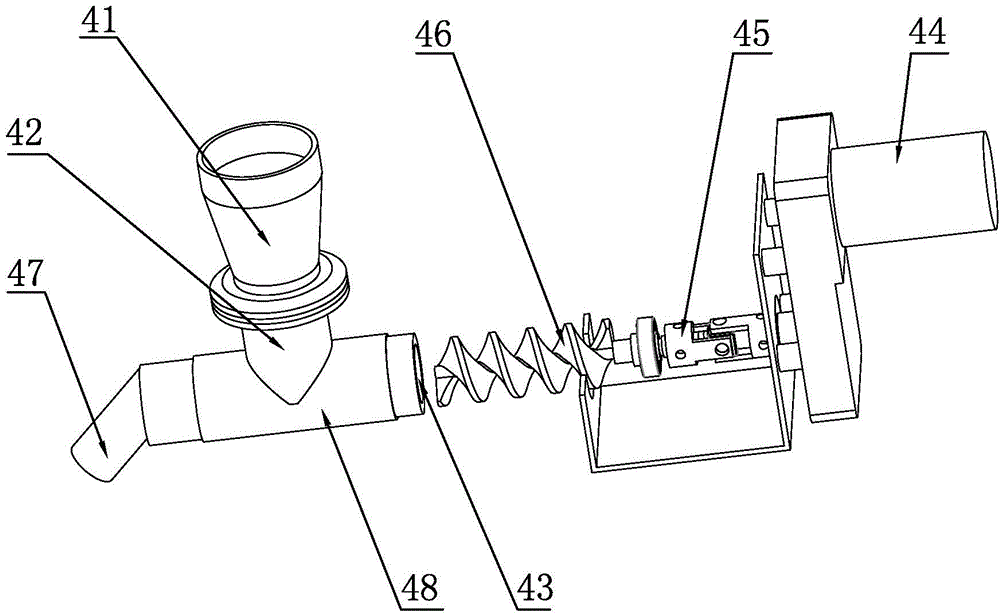

[0031] Such as Figure 1-Figure 4 As shown, the raw material storage box 1 and the feeding device 4 are connected through a connecting portion 41. A filling hopper 33 is provided at the outlet 47 of the feeding device 4, and one end of the filling hopper 33 is connected to the outlet 47. The other end of the bucket 33 is connected to the filling port 323 of the filling part 32, the filling part 32 is arranged vertically, and is directly opposite to the coffee capsule container 5 below, and the air cylinder 31 and the filling part 32 are fixedly arranged and located opposite to each other. The other side of the hollow cylindrical port 321.

[0032] The specific implementation process of the present invention: the coffee powder is put into the raw material storage box 1, and the stirring rod 12 is driven by the stir...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap