45-degree distributing mechanism for automatic tire production line

A technology of automatic production line and diversion mechanism, which is applied in the direction of conveyor objects, transportation and packaging, etc., to achieve the effects of easy problem discovery and maintenance, simple structure and principle, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

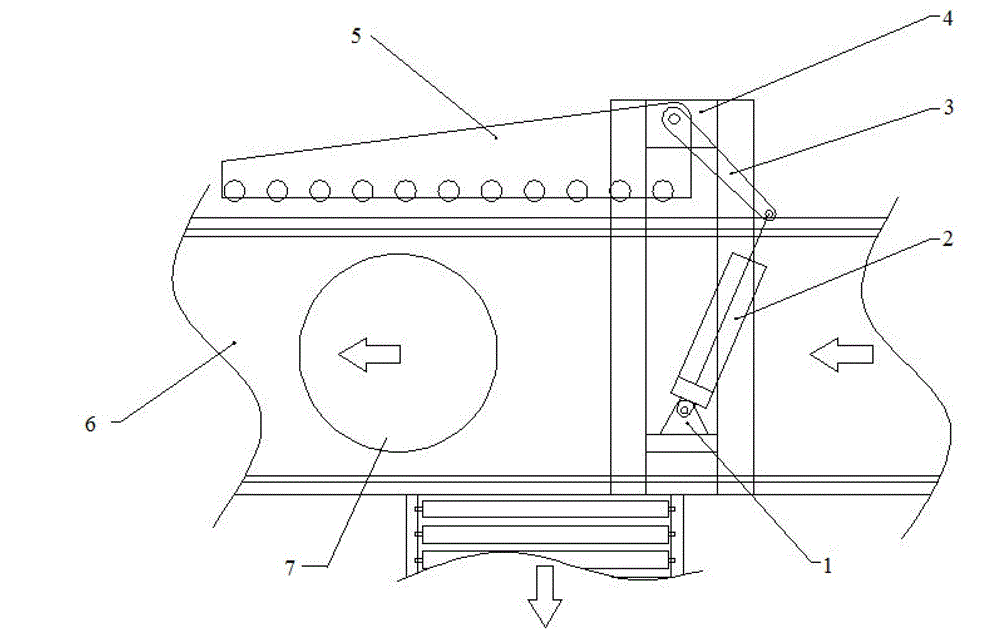

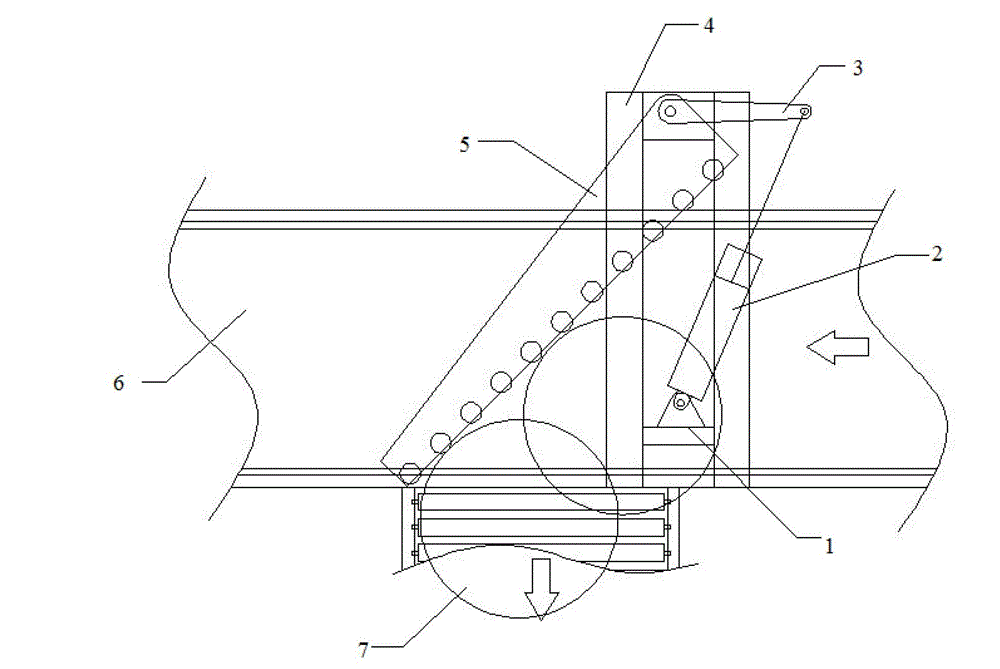

[0019] Such as Figure 1~2 As shown, a 45-degree diversion mechanism for an automatic tire production line includes a diverter base 4, a free roller conveyor 5, a cylinder 2, a cylinder fixing bracket 1 and a connecting rod 3, and the free roller conveyor 4 and the connecting rod The rods 3 are connected together and fixed on the base 1 of the diverter. One end of the connecting rod 3 is welded to the free roller conveyor 4 through a pin shaft and fixed on the base 1 of the diverter. The other end of the connecting rod is connected to the cylinder 2. , The cylinder 2 drives the connecting rod 3 to rotate around the pin shaft, and the rotation angle is 45 degrees. Cylinder 2, cylinder fixed bracket 1 and connecting rod 3 form a linkage mechanism, described connecting rod 3 connects cylinder 2, and cylinder 2 is arranged on cylinder fixed bracket 1, and cylinder fixed bracket 1 is installed on belt conveyor 6 bottoms, and cylinder 2 Control the conveying and rotation of the fre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com