Projection-type capacitive touch white board manufacturing method and projection-type capacitive touch white board

A technology of capacitive touch and manufacturing methods, applied in the direction of electrical digital data processing, input/output process of data processing, instruments, etc., can solve problems such as prone to misoperation, insensitive operation, misoperation, etc., and reduce misoperation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to have a clearer understanding of the technical features, objectives and effects of the present invention, the specific embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

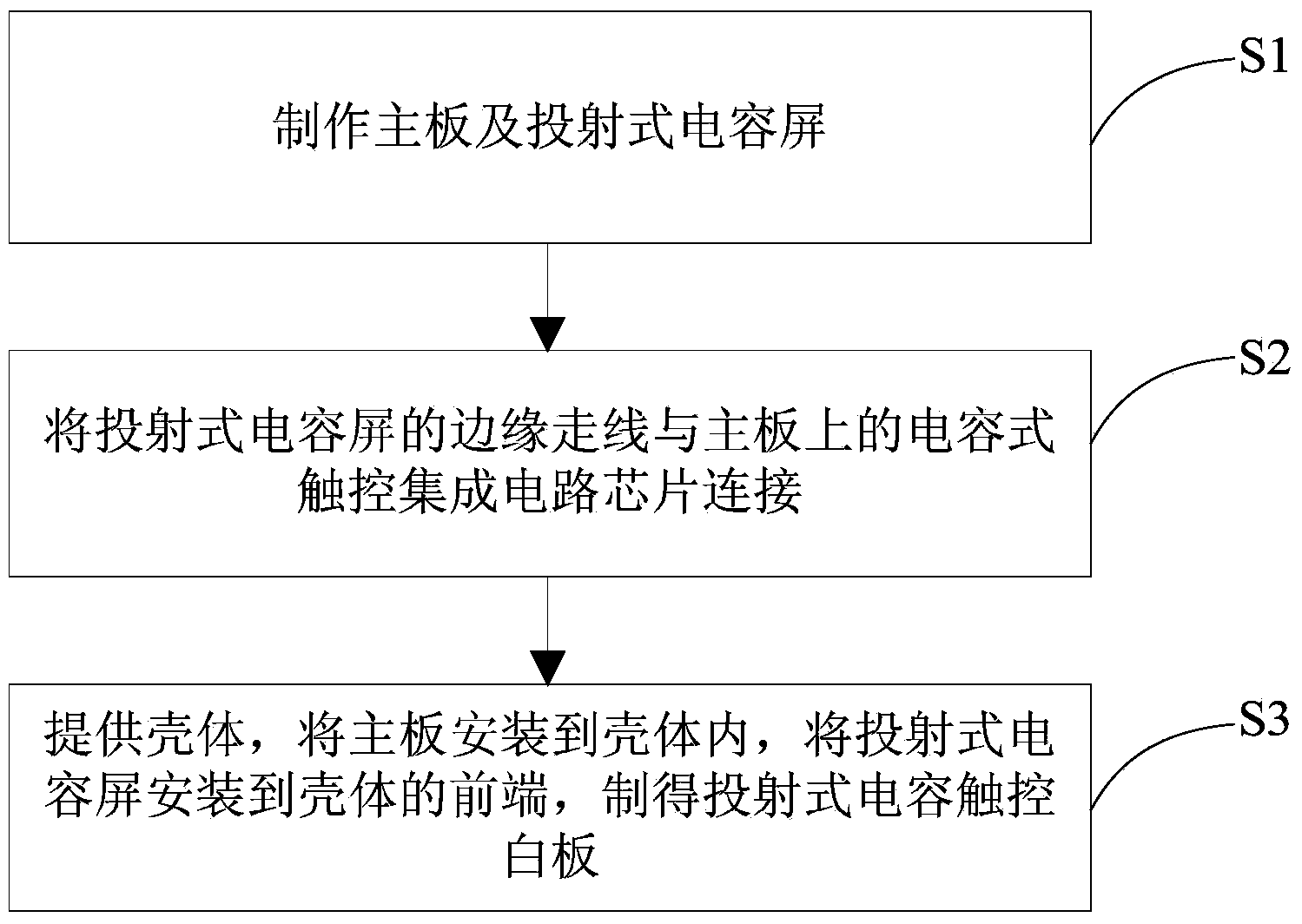

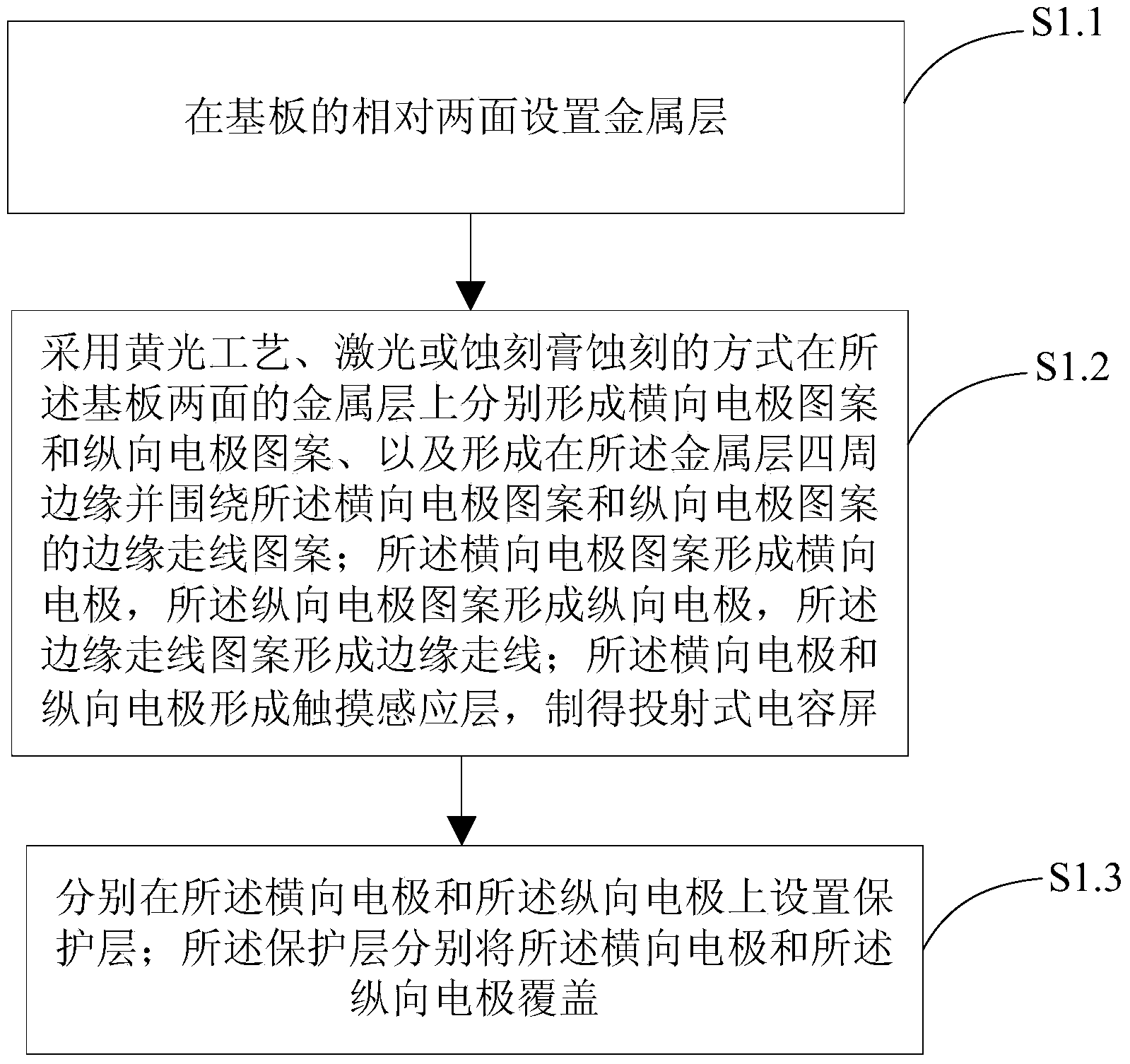

[0043] Such as figure 1 As shown, the manufacturing method of the projected capacitive touch whiteboard according to an embodiment of the present invention includes the following steps:

[0044] S1. Making motherboards and projected capacitive screens. The manufacture of the motherboard can be realized by using existing technology.

[0045] S2. Connect the edge traces of the projected capacitive screen with the capacitive touch integrated circuit chip on the motherboard.

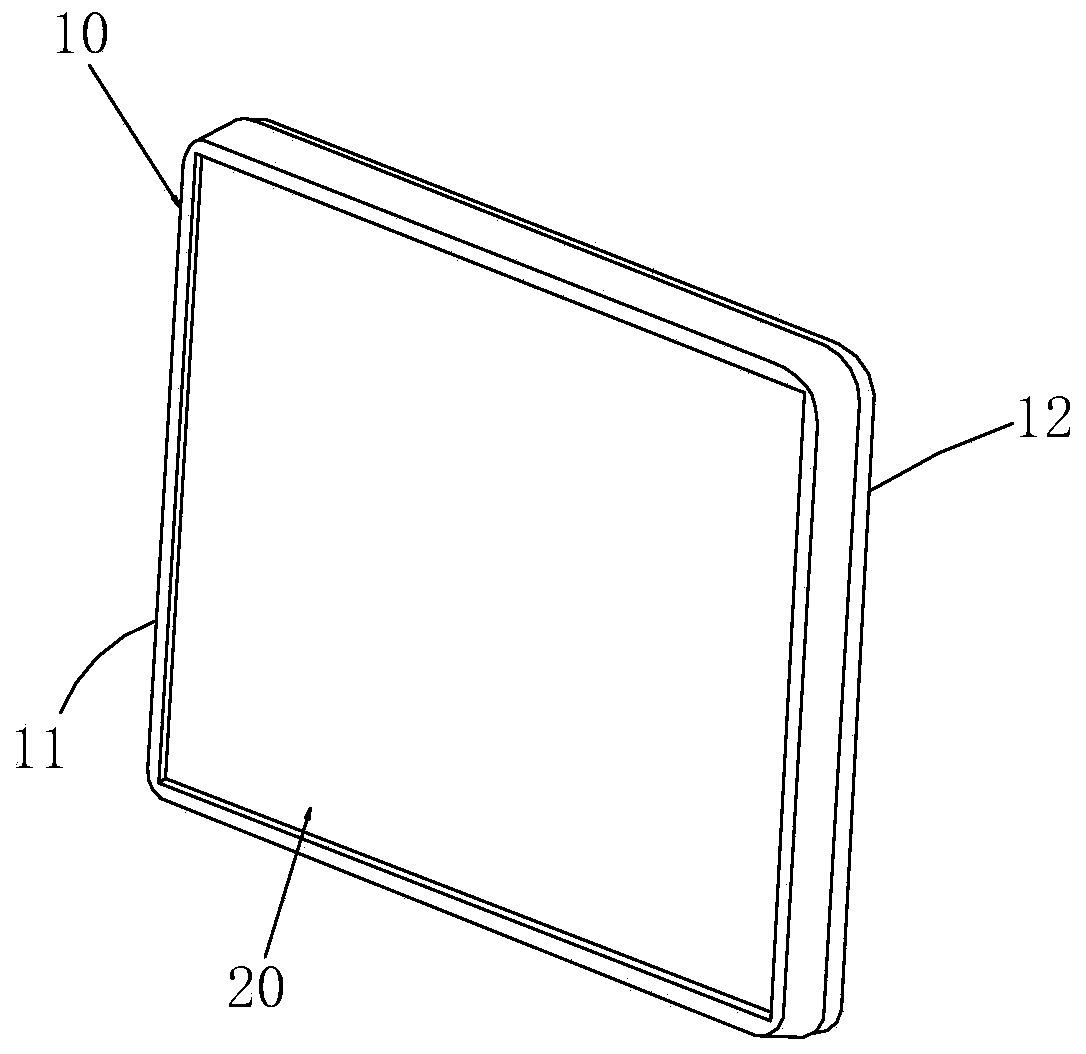

[0046] S3. Provide a shell, install the motherboard into the shell, and install the projected capacitive screen on the front end of the shell to make a projected capacitive touch whiteboard. The shell can be made in advance, and made into a corresponding shape accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com