A Residual Charge Discharge Device for Valve Hall of Converter Station

A discharge device and residual charge technology, applied to circuit devices, emergency protection circuit devices for limiting overcurrent/overvoltage, emergency protection circuit devices, etc. Strict clearance requirements and other issues, to achieve the effect of favorable electrical layout, avoid safety accidents, and save the total investment of the project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below with reference to the accompanying drawings and embodiments.

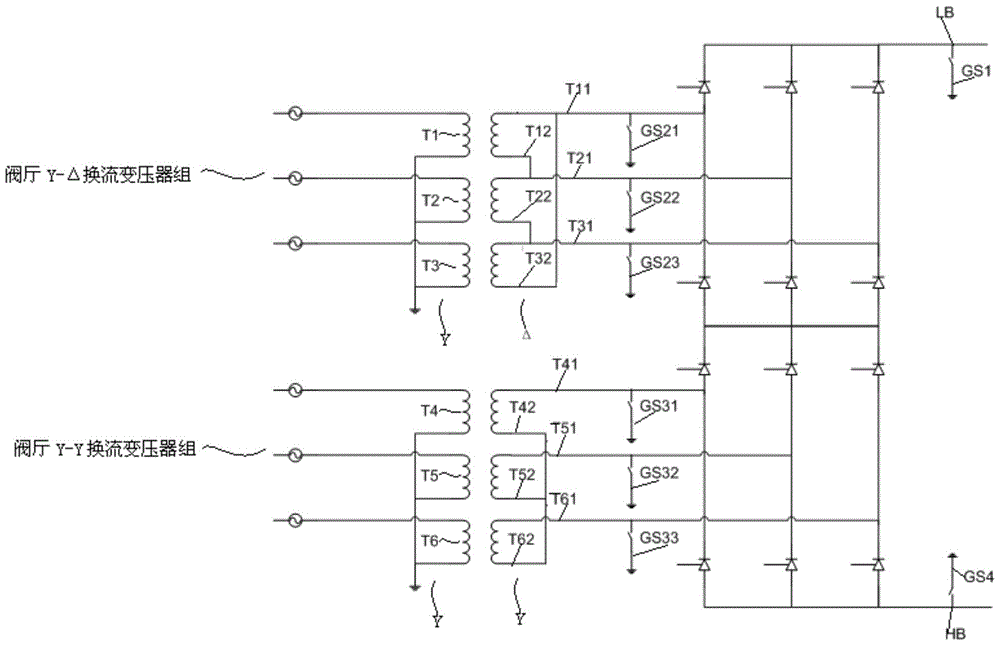

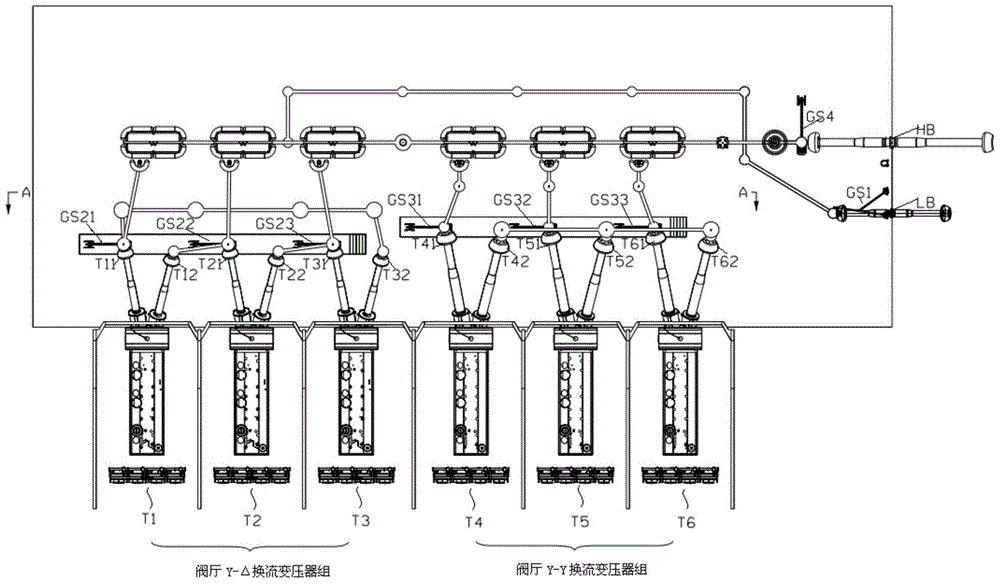

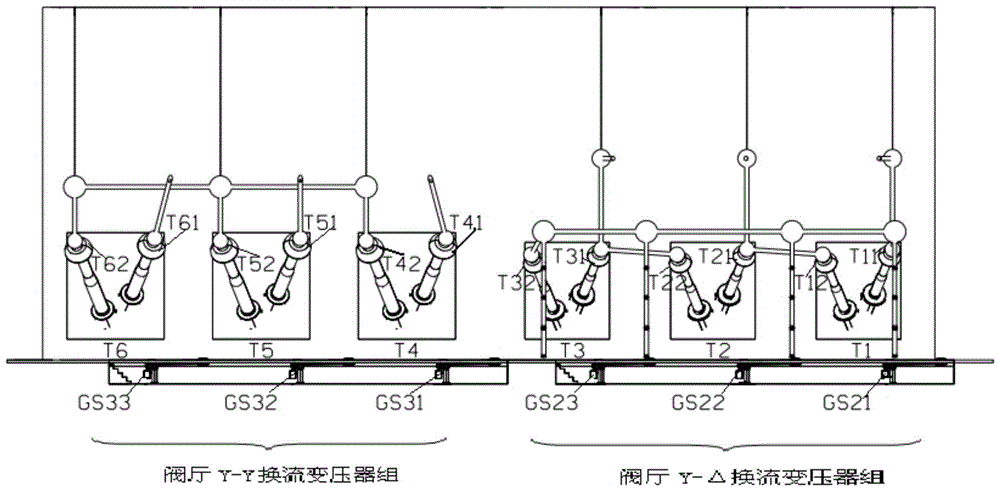

[0026] The present invention (such as Figure 4~6 shown) and existing technologies (such as Figure 1~3 The same point as shown) is that a ground knife GS1 for the low-voltage pole line point of the valve hall is arranged on the busbar where the low-voltage pole line point LB of the valve hall is located, which adopts the side wall type. A ground knife GS4 for the high-voltage pole point of the valve hall is arranged on the busbar where the high-voltage pole point HB of the valve hall is located, and it adopts a vertical type.

[0027] The difference between the present invention and prior art comprises two points:

[0028] 1) A ground knife is arranged on the connection bus between the valve-side terminal of the A-phase converter transformer and the valve-side terminal of the C-phase converter transformer of the Y-Δ converter transformer group, that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com