Digital enamel ink

A digital and glaze technology, applied in the field of high-emission digital glaze ink, can solve the problems that do not have the best results using conventional enamel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0076] Example 1: Digital glaze ink

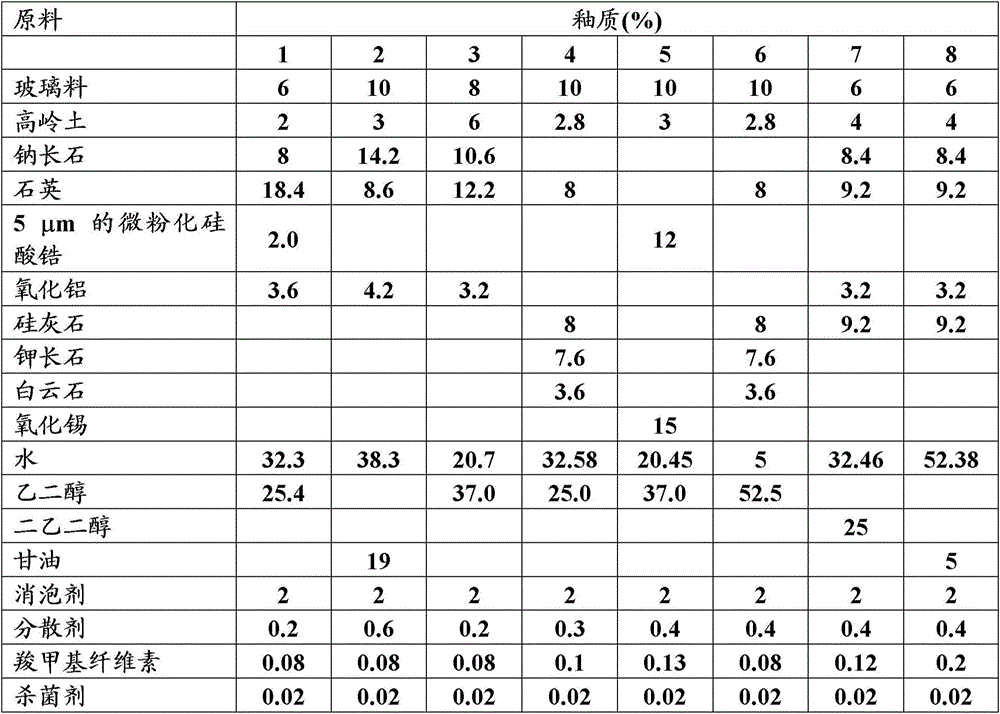

[0077] Table 1 shows multiple examples of the digital glaze ink of the present invention

[0078]

[0079] Table 1: Digital glaze ink

[0080] Table 2 shows the physical properties of the ink of the present invention

[0081] Physical properties

[0082] Table 2: Physical properties of the ink of the present invention

Example Embodiment

[0083] Example 2: Method for preparing digital glaze ink of the present invention

[0084] The general procedure for preparing the digital glaze ink of the present invention includes the following steps:

[0085] -Mixed solid raw materials,

[0086] -Put all or part of the water and all or part of the remaining liquid components (solvent and liquid additives) of the solid and the digital enamel in the grinder,

[0087] -Grind in a ball mill for 5 hours to 15 hours, the balls are loaded and distributed in specific sizes to obtain the desired particle size,

[0088] -Control the particle size, which is measured by a laser beam diffraction device in a wet method to verify that a suitable particle size distribution is obtained.

[0089] -Add the remaining water and liquid components (solvent and liquid additives) not introduced during the initial grinding.

[0090] -Discharge the grinder, sieving the material at 80μm, and then filter at 40μm to eliminate the possibility of coarse particles, w...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap