Expansion mold locating mechanism for production of washing machine internal cylinder

A positioning mechanism and washing machine technology, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of large positioning error, rough and inflexible structure, and difficulty in adapting to automatic assembly line production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below according to the drawings and embodiments.

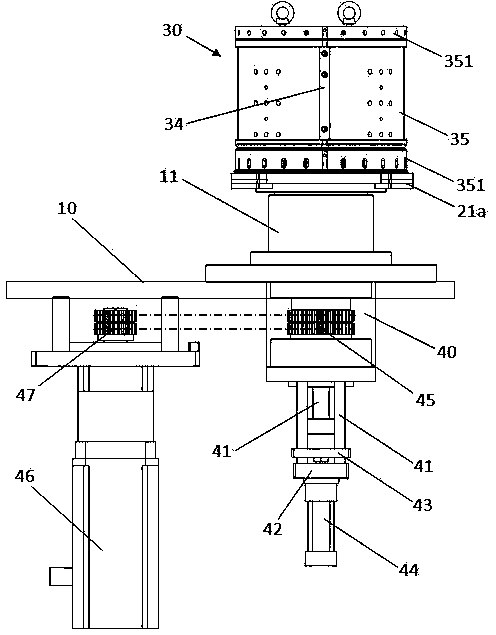

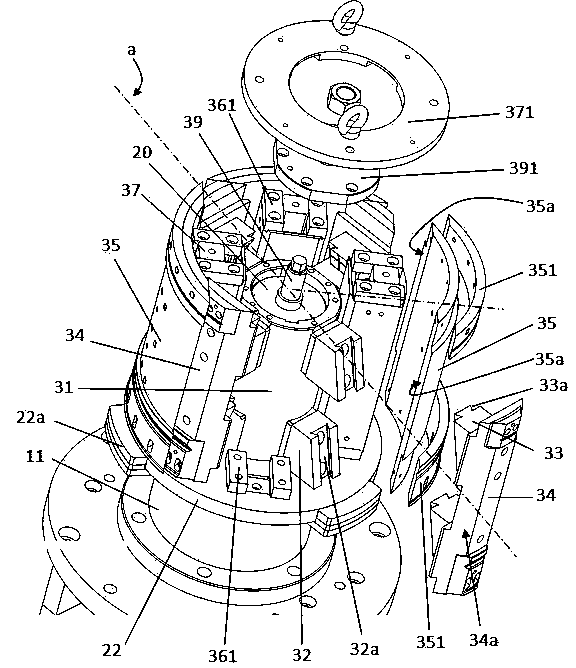

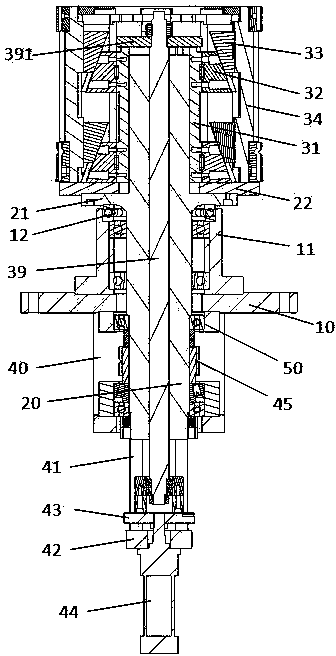

[0021] like figure 1 , figure 2 and image 3 As shown, a mold expansion positioning mechanism for the production of the washing machine inner cylinder described in the embodiment of the present invention includes a workbench 10, a rotatable hollow shaft 20 is arranged on the workbench 10, and an expansion mold is set on the hollow shaft 20. The expansion and contraction device 30 includes a sliding sleeve 31 axially slidingly sleeved on the outside of the hollow rotating shaft 20. The outer wall of the sliding sleeve 31 is radially and evenly spaced with inner wedge-shaped sliders 32, and the inner wedge-shaped sliders 32 are slidably connected with Outer wedge-shaped slider 33, the outer side of outer wedge-shaped slider 33 is fixedly connected with push plate 34, and the both sides of push plate 34 are respectively provided with outer landslide 34a, between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com