Convex point forming die for automobile safety belt retractors

A technology for seat belt retractors and automobiles, which is applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of bump surface roughness, affecting the strength of the bottom plate, and high stamping pressure of the bottom plate, etc., and achieve good smoothness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

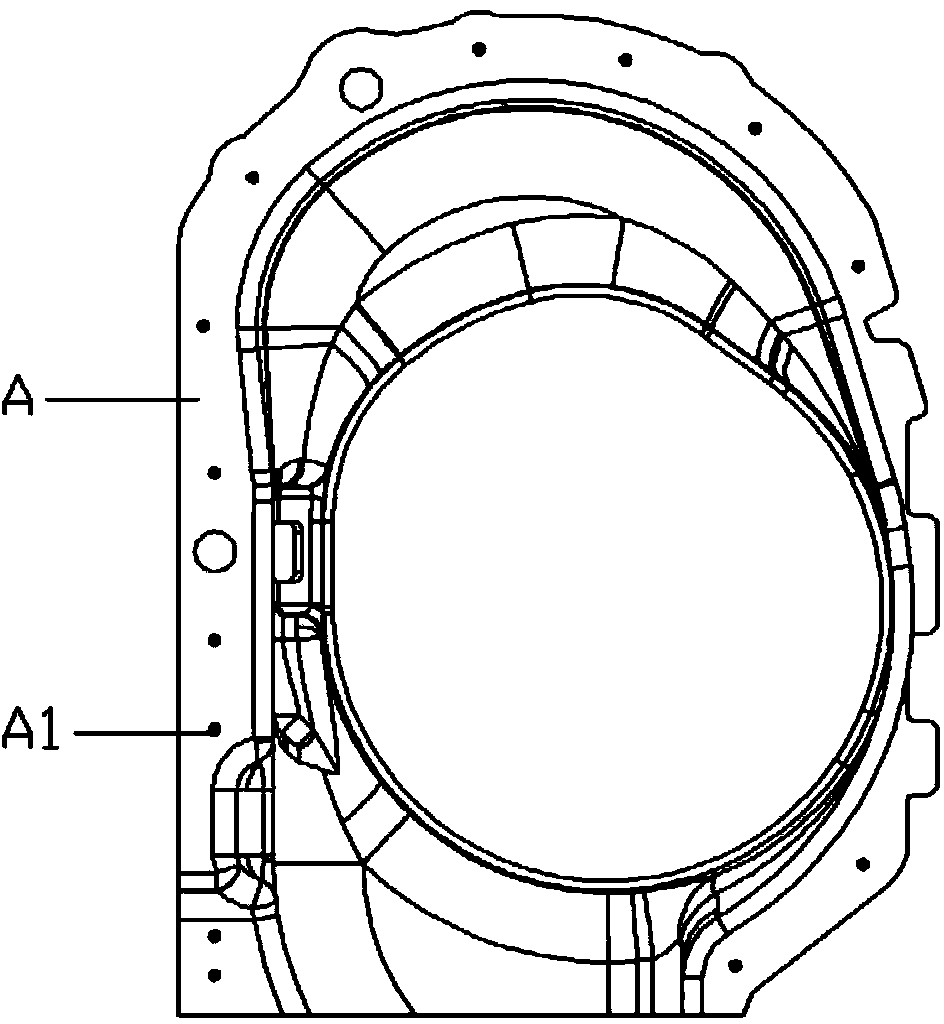

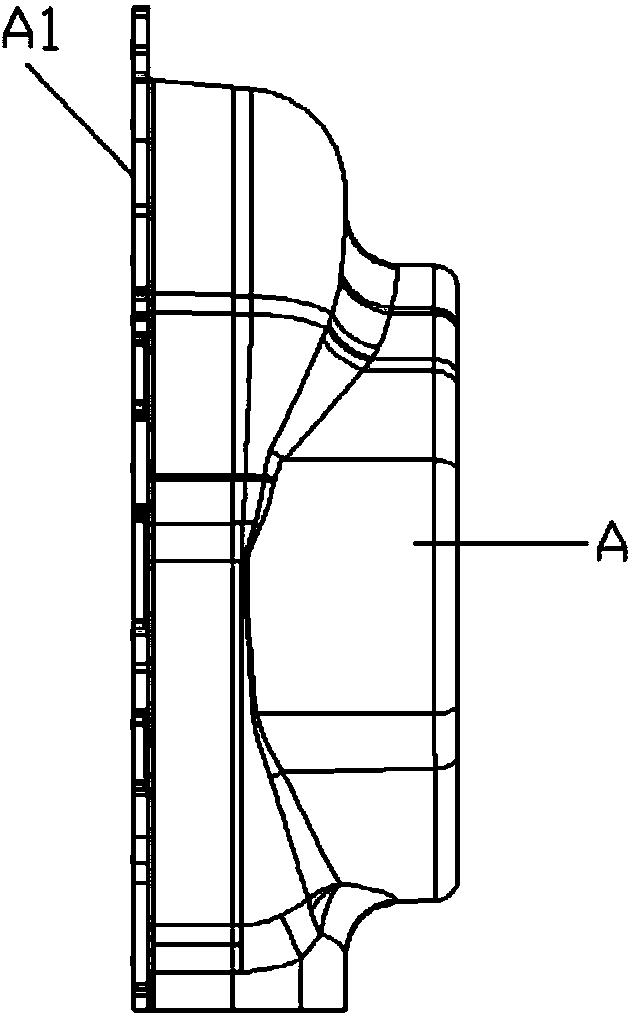

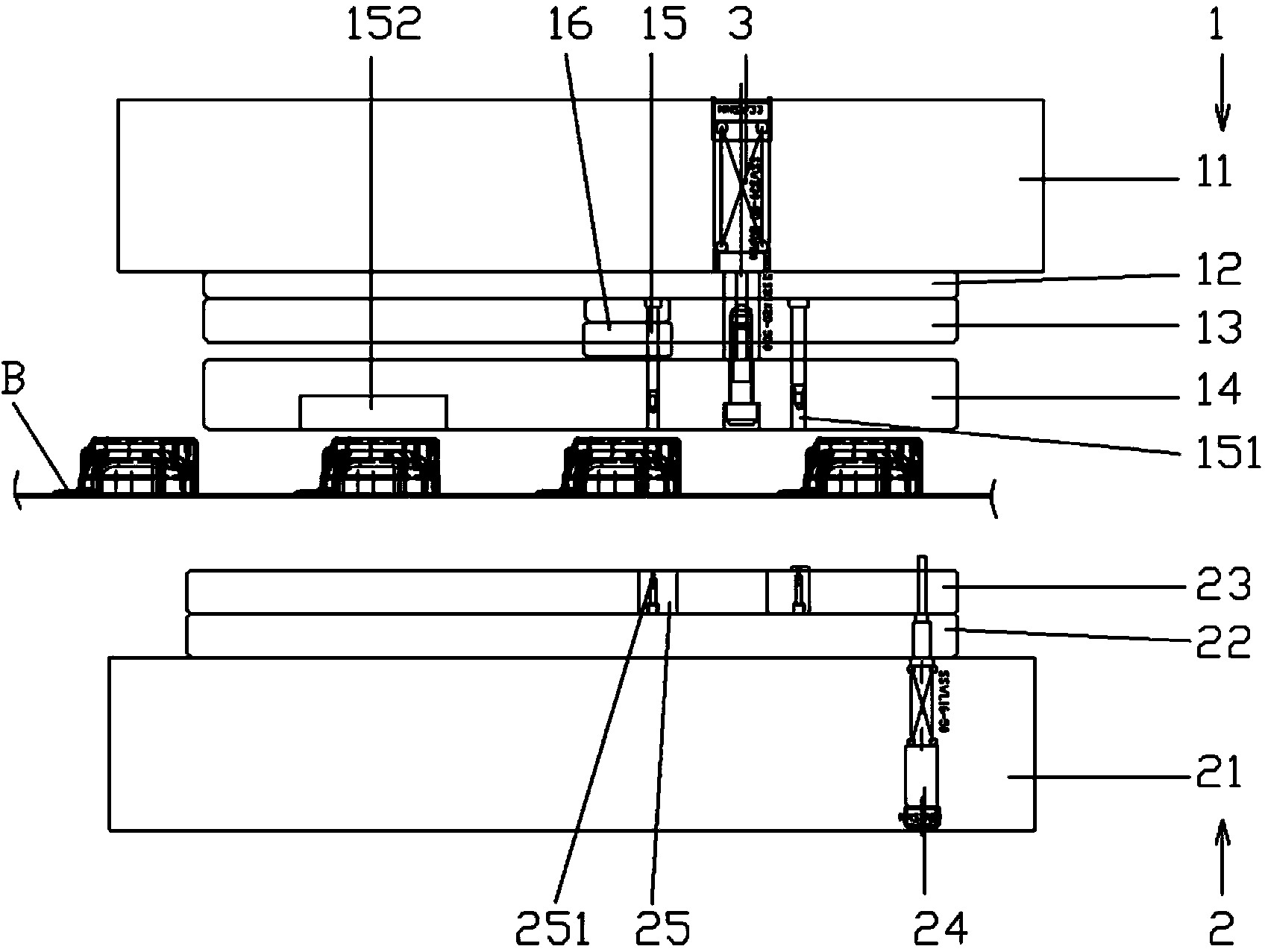

[0021] Example: see image 3 , 4 As shown, the mold for embossing the automotive safety belt retractor includes an upper mold 1 and a lower mold 2. The upper mold 1 is composed of an upper mold base 11, an upper mold upper backing plate 12, an upper mold splint 13 and an upper mold pressure plate 14. At least three upper mold carbon gas springs 3 are fixed on the upper mold base 11, the piston rod of the upper mold carbon gas spring 3 and the upper mold pressure plate 14 are fixed together by bolts, the upper mold upper backing plate 12 and the upper mold clamping plate 13 are screwed together Fixed together, the piston rod of the upper mold carbon gas spring 3 is inserted into the preset hole of the upper mold backing plate 12 and the upper mold splint 13, and the upper mold punch 15 is fixed on the upper mold backing plate 12 and the upper mold splint On 13, the front end of the upper die dotting punch 15 is spherical, and the upper die pressing plate 14 is formed with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com