Auxiliary brake friction damping device of downward belt conveyor

A belt conveyor and auxiliary braking technology, which is applied in the direction of conveyor, transportation and packaging, etc., can solve the problem of redundant sliding force, and achieve the effect of avoiding speeding accidents and slowing down the speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

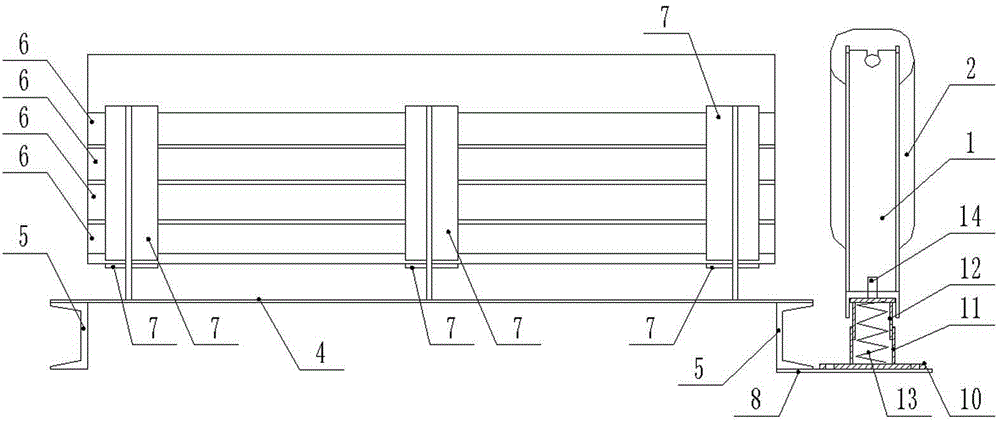

[0020] The auxiliary brake friction damping device of the down belt conveyor is composed of a damping frame, a V-shaped idler frame and two spring dampers.

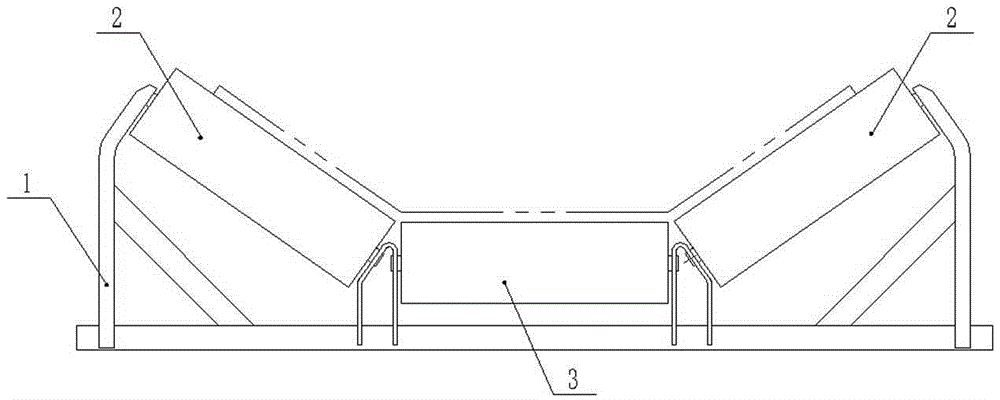

[0021] The V-shaped idler frame includes two side idlers 2 and an intermediate idler 3 supported on the idler base 1, and the two side idlers 2 and the intermediate idler 3 form a V-shaped groove;

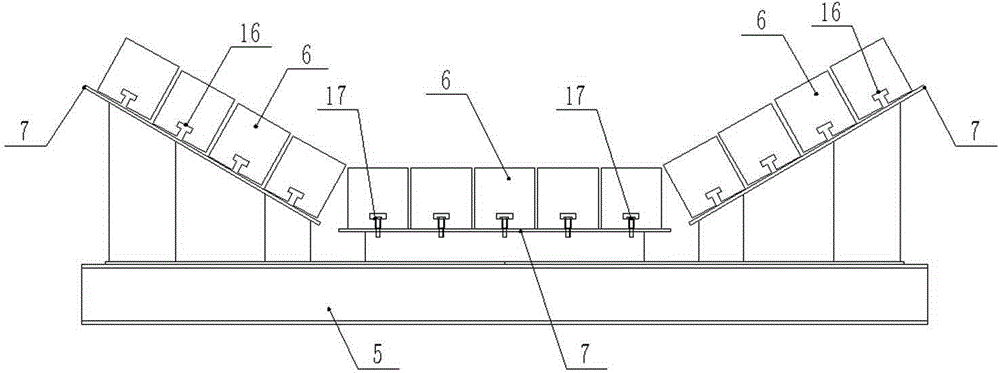

[0022] Described damping frame comprises two channel steels 5 that are arranged in parallel below the support plate 4, some damping strips 6, and described some damping strips 6 are supported above the support plate 4 by some support strips 7, and the length direction of the damping strips 6 is in line with the belt The conveying direction is in the same direction, and several damping strips 6 form two side damping strips and one middle damping strip, and the groove formed by the two side damping strips and one middle damping strip has the same angle and size as the V-shaped groove; Two connecting plates 8 are respectively fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com