Auxiliary Braking Friction Damping Device for Downward Belt Conveyor

A belt conveyor and auxiliary braking technology, which is applied in the direction of conveyor, transportation and packaging, etc., can solve the problem of redundant sliding force, and achieve the effect of avoiding speeding accidents and slowing down the speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

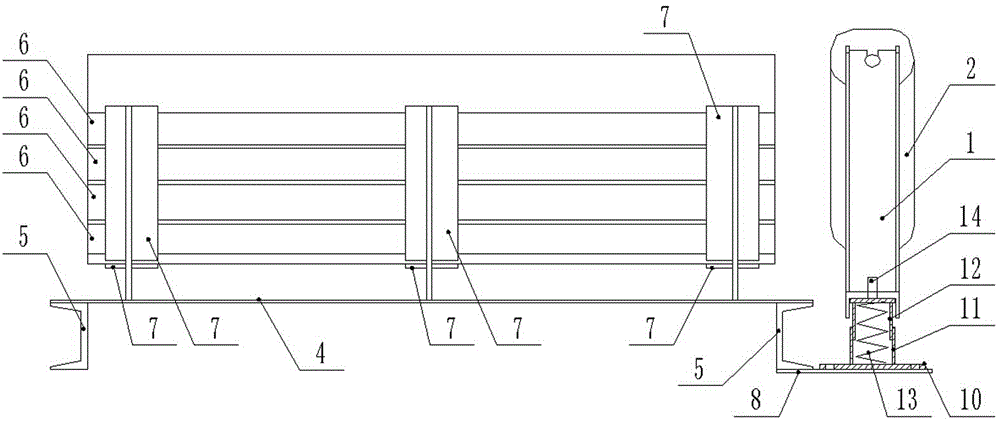

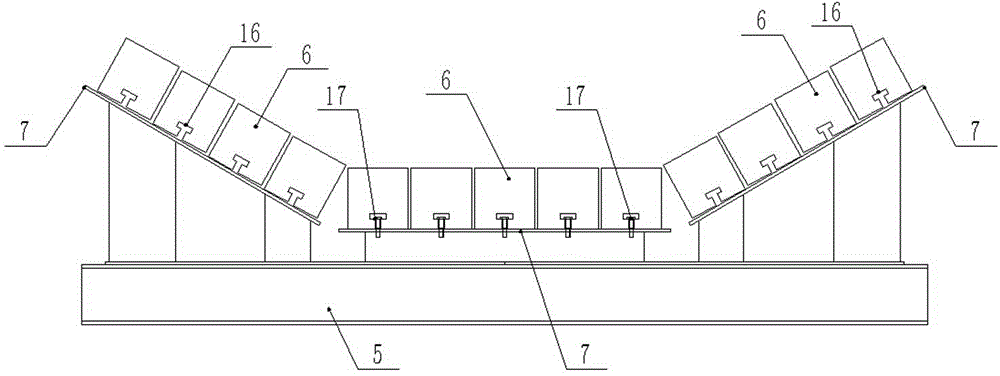

[0020] The auxiliary brake friction damping device of the downward belt conveyor is composed of a damping frame, a V-shaped roller frame and two spring dampers.

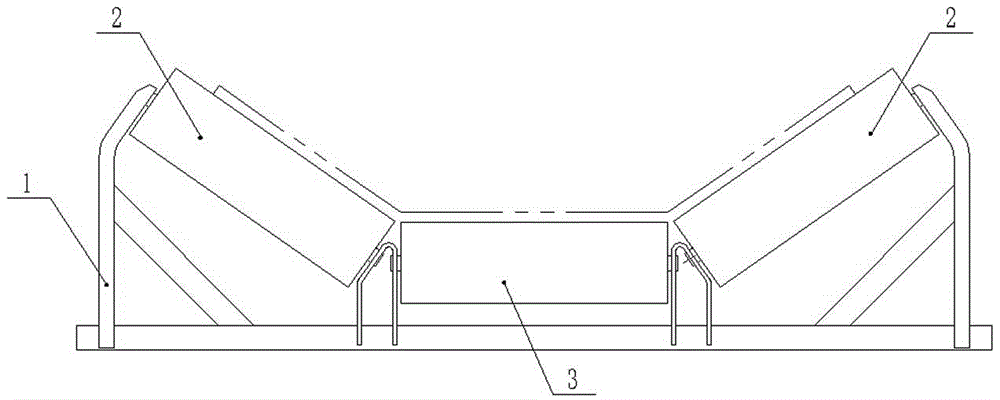

[0021] The V-shaped roller rack includes two side rollers 2 and a middle roller 3 supported on the roller rack base 1, and the two side rollers 2 and the middle roller 3 are surrounded to form a V-shaped groove;

[0022] The damping frame includes two steel channels 5 arranged in parallel below the support plate 4, a number of damping strips 6, the damping strips 6 are supported above the support plate 4 by a number of support strips 7, and the length direction of the damping strips 6 and the belt The conveying direction is the same, and a plurality of damping strips 6 form two side damping strips and a middle damping strip. The two side damping strips and one middle damping strip are surrounded by a groove with the same angle and size as the V-shaped groove; A connecting plate 8 is fixed at the lower two ends of the chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com