Composite drive FAST cable detection robot system

A robot system and robot technology, applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve problems such as poor stability and poor obstacle-crossing ability, and achieve the effects of poor safety, high cost, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

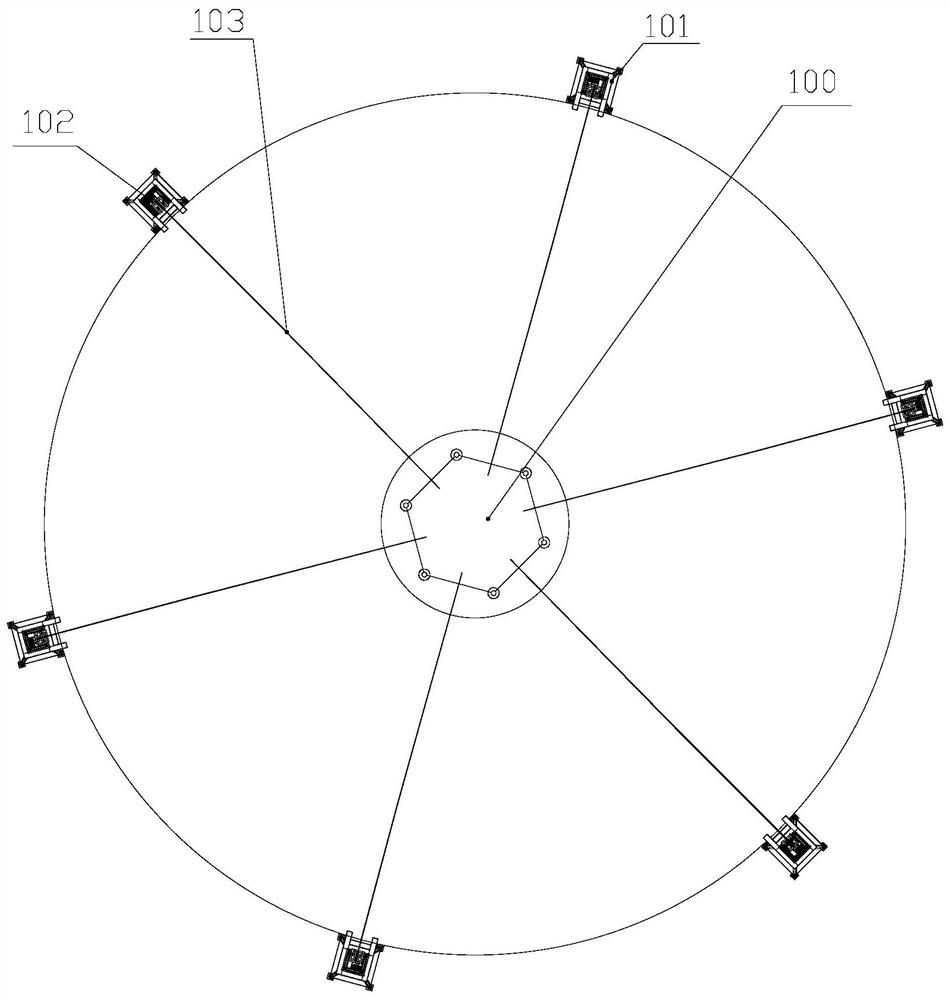

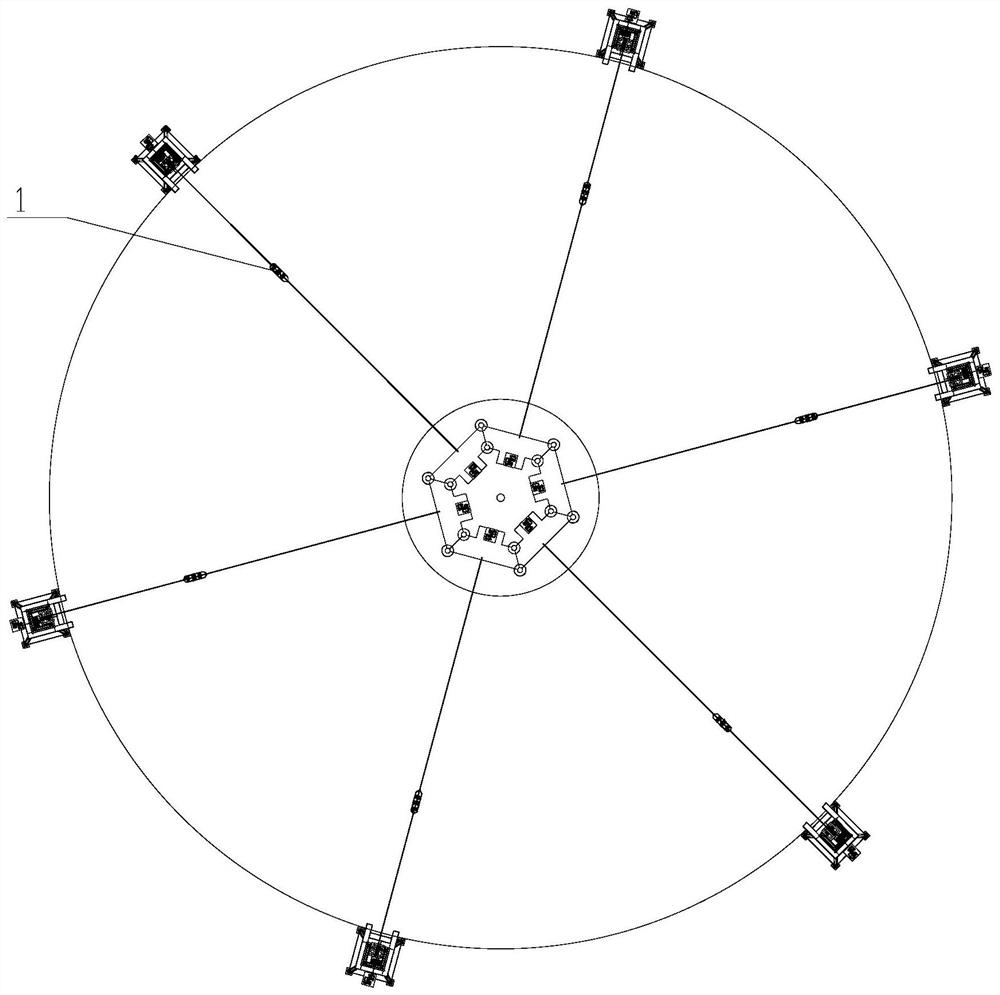

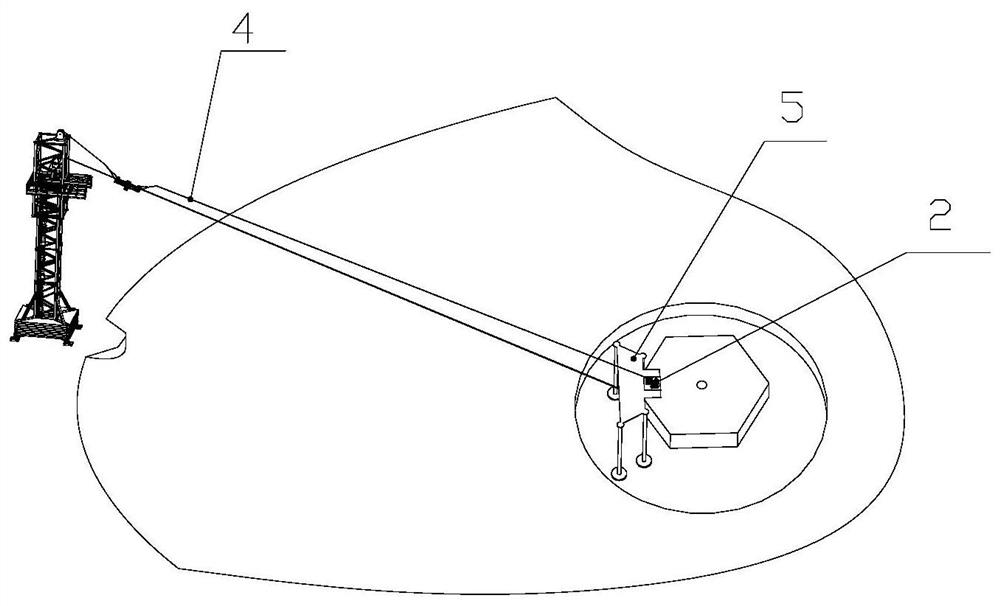

[0044] Specific implementation mode one: combine Figure 1-18 Describe this embodiment, a FAST cable detection robot system driven by a compound, which includes a cable detection robot 1 slidingly installed on the cable 103 to be tested and a first traction device 2 that controls the cable detection robot 1 to move on the cable 103 to be tested and the second traction device 3, the front and rear ends of the cable detection robot 1 are respectively connected with the first traction device 2 and the second traction device 3 by a traction cable 4, and each hanging point of the feed cabin 100 is fixedly installed There is a feed cabin operating platform 5, the number of the first traction devices 2 is equal to the number of support towers 101 and a first traction device 2 is installed correspondingly on each support tower 101, the number of the second traction devices 3 The number is equal to that of the first traction device 2 and the second traction device 3 is correspondingly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com