Reinforced gantry lifting hook for hot closed treatment slag

A technology of fixing gantry hooks and hot slag, which is applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems that affect the safety and service life of the hook, the force of the rivet, and the deformation of the hook, etc., to improve stability Sex and safety, improved life, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

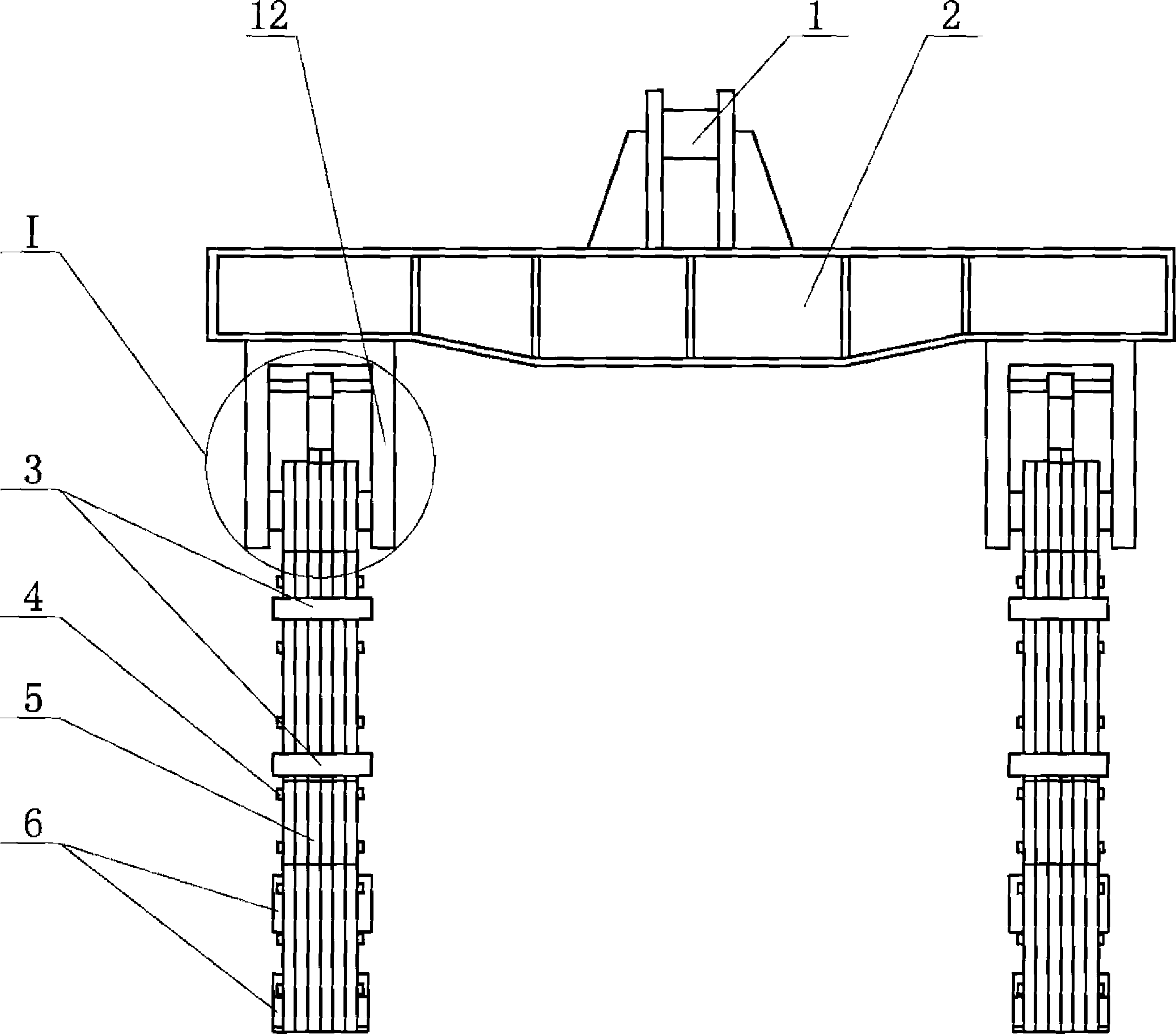

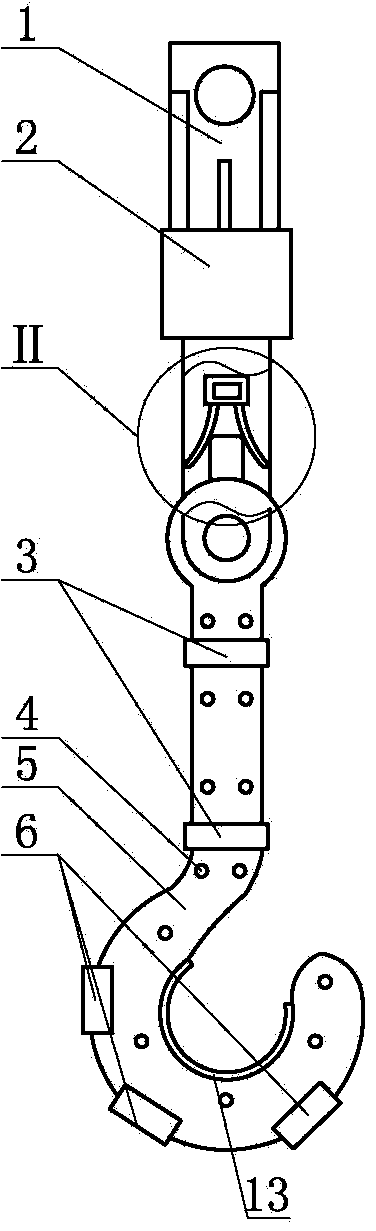

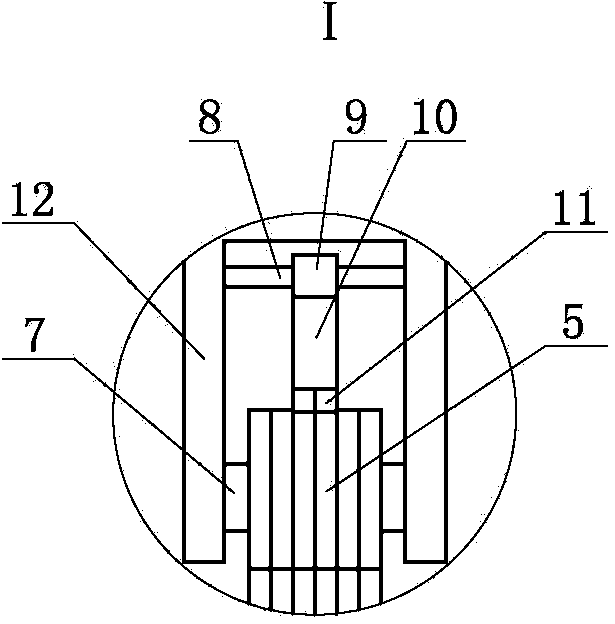

[0009] A reinforced gantry hook for hot slag, such as figure 1 and figure 2 As shown, the horizontal support frame 2 is included, the upper end of the horizontal support frame 2 is provided with a hanger 1, and the hanger 1 cooperates with the gantry locomotive, and a hanger 12 is arranged at the lower part of both ends of the horizontal support frame 2, and the hanger 1 cooperates with the gantry locomotive. The cross-section of the hanger 12 is an inverted U-shape. The middle part of the hanger 12 is provided with a horizontal swing shaft 7. The hook body 5 is hoisted on the swing shaft 7. The hook 5 can swing around the swing shaft 7. Each hook body 5 consists of several Each plate can be welded as a whole. Several hoop rings 3 are arranged on the outer periphery of the hook body 5. The hoop ring 3 is located in the middle of the hook body 5. Several hoop rings are arranged on the side of the hook body 5. The hoop half-ring 6, the hoop half-ring 6 is located at the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com