Flexible and retractable auxiliary blade mechanism of vertical-axis wind turbine

A technology of auxiliary blades and vertical shafts, applied in the field of wind turbines, can solve the problems of low wind energy utilization efficiency and poor start-up performance of lift-type wind turbines, and achieve the effects of improving wind energy utilization efficiency, scientific and reasonable wind energy utilization, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

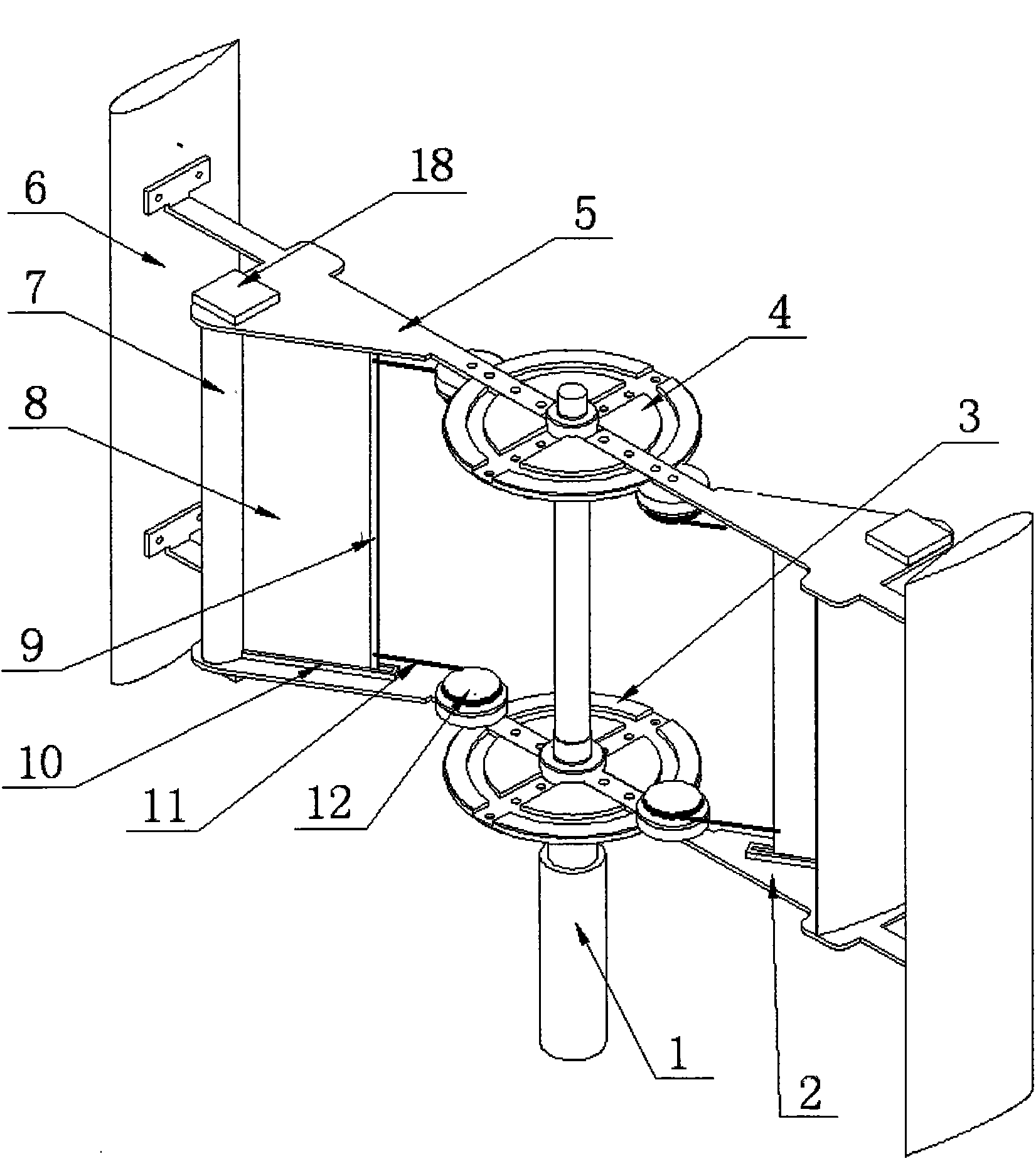

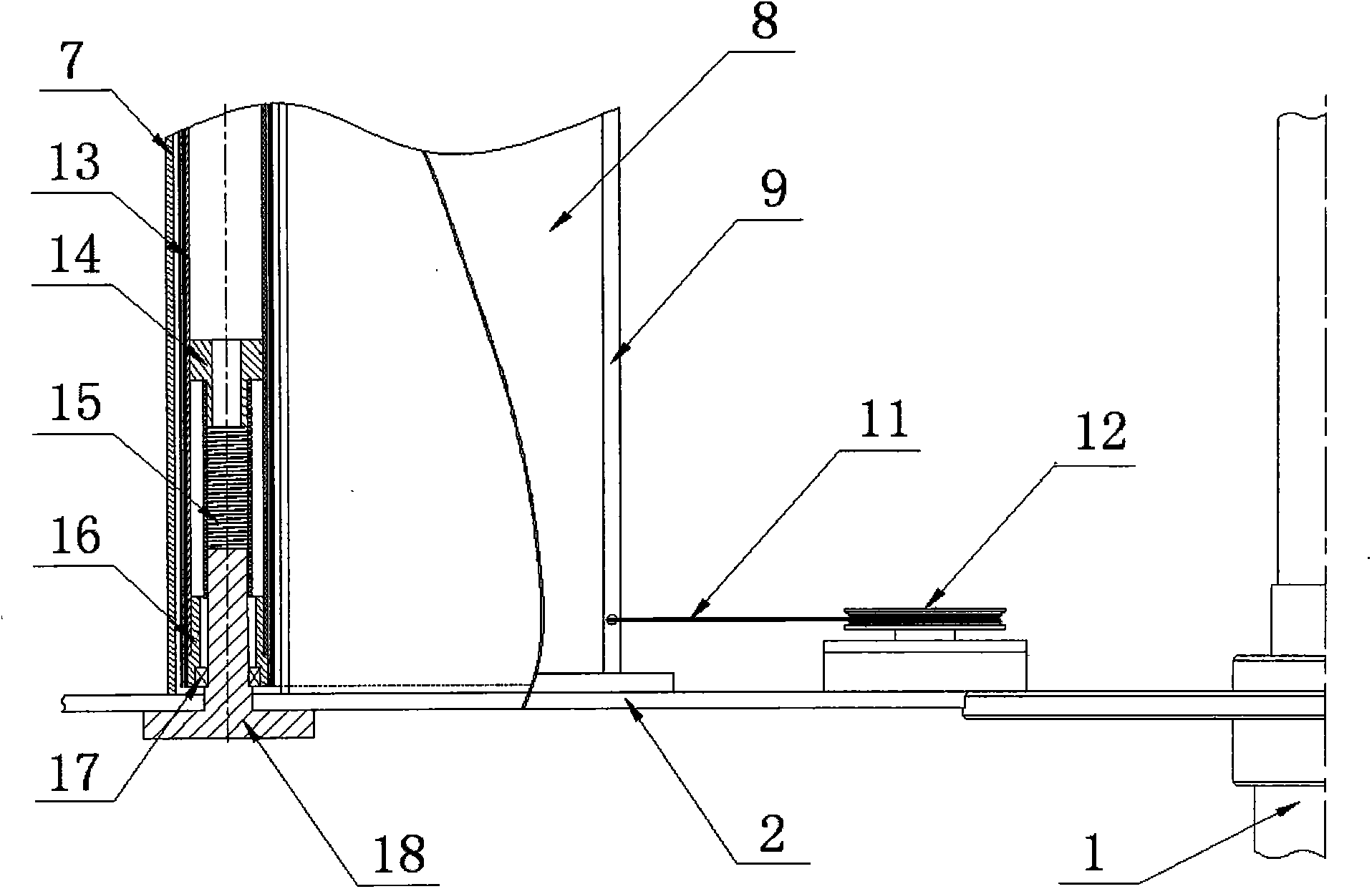

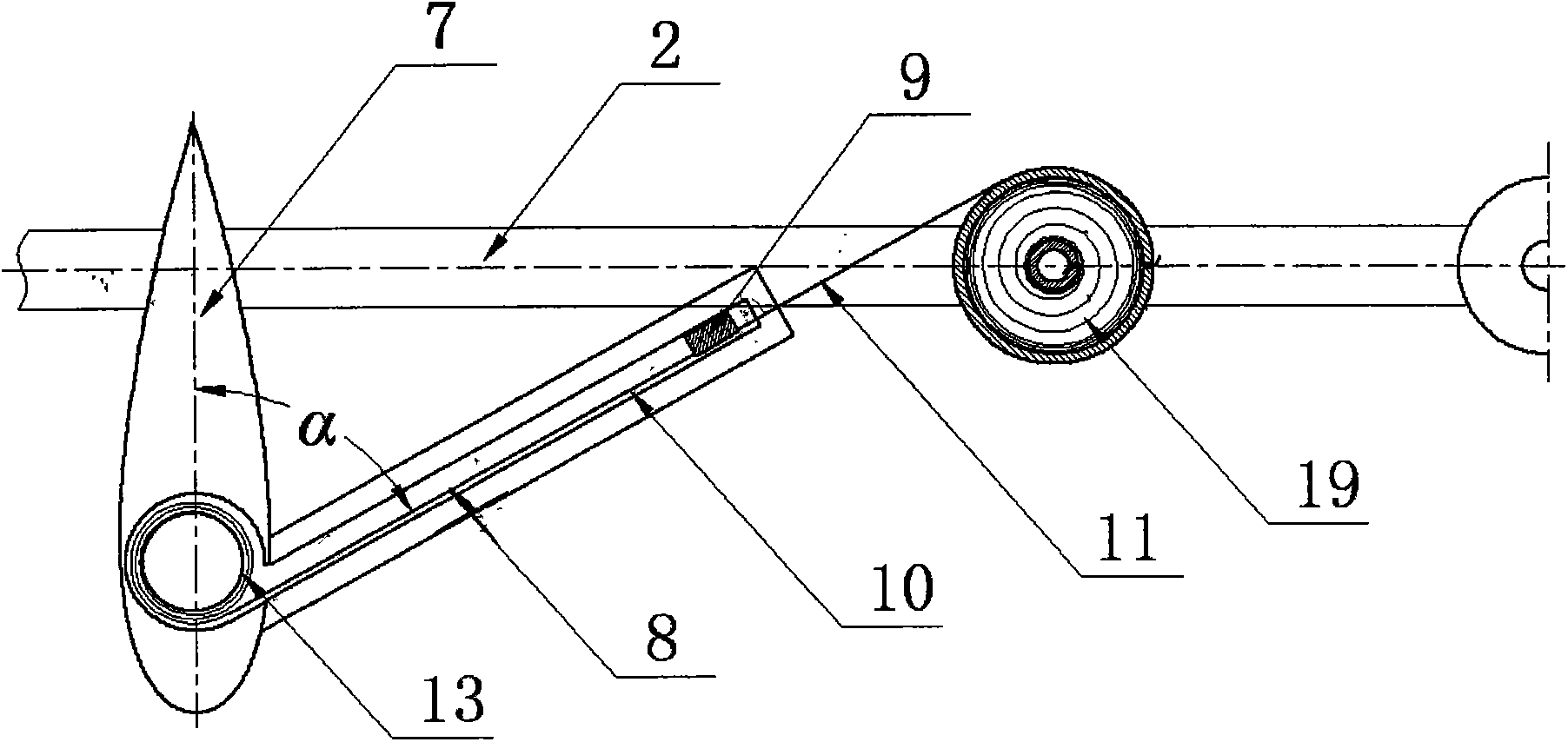

[0013] A flexible and retractable auxiliary blade mechanism for a vertical axis wind turbine, in which an upper flange 4 and a lower flange 3 are sequentially fixed on a main shaft 1 from top to bottom, and fixed on the upper flange 4 and lower flange 3 respectively The upper beam 5 and the lower beam 2 are respectively fixed with main blades 6 on the outer ends of the upper and lower beams 5 and 2, and are located between the main blade 6 and the main shaft 1 on the sides of the upper and lower beams 5 and 2. The auxiliary blade 7 is fixedly fitted at the middle part, and a cylindrical hole is vertically opened at the maximum thickness part of the auxiliary blade 7. Fixing bolts 14 and bearing sleeves 16 are respectively fixed in sequence on the upper and lower sides, and the fixed shafts 18 of the fixed bearings 17 are respectively inserted and fixed on the two sides of the upper and lower beams 5 and 2, and the fixed shafts 18 are mated in the In the cavity of the bearing s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com