Method and device for improving performance of resistance-type vertical axis wind turbine

A wind turbine and resistance type technology, applied in the field of resistance type vertical axis wind turbines, can solve problems such as waste, and achieve the effect of reducing power generation cost, stable effect and reducing start-up wind speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

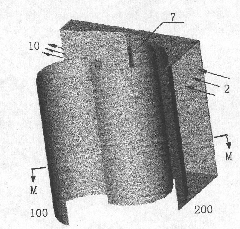

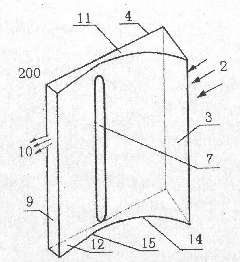

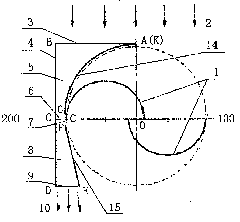

[0018] refer to figure 1 , is a typical three-dimensional structure schematic diagram of a wind turbine combined with the present invention. It can be seen that the wind turbine combined with the present invention is composed of the rotor 100 and the additional device 200 . The wind turbine rotor 100 is a common drag wind turbine, including two or more blades, and there is no limitation on the type of the rotor, and its structure can be single-layer, multi-layer or spiral. The rotor blades can be staggered from each other with gaps between them, or can be connected to each other without gaps. The height of the additional device 200 is 1.1 to 1.3 times the height of the rotor 100, mainly a contraction-expansion duct closed up and down, which can rotate coaxially with the wind turbine rotor 100 (not shown) to ensure that it is always aligned with the wind direction , so that the wind 2 flows in from its inlet, and flows out of the airflow 10 at the outlet; when the wind 2 blow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com