Wind power generation module and matrix wind power generation device formed by same

A wind power generation device, a matrix technology, is applied in the wind turbine combination, the configuration of installing/supporting the wind turbine, the control of the wind turbine, etc. large, increase power generation, and facilitate the effect of breeze starting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

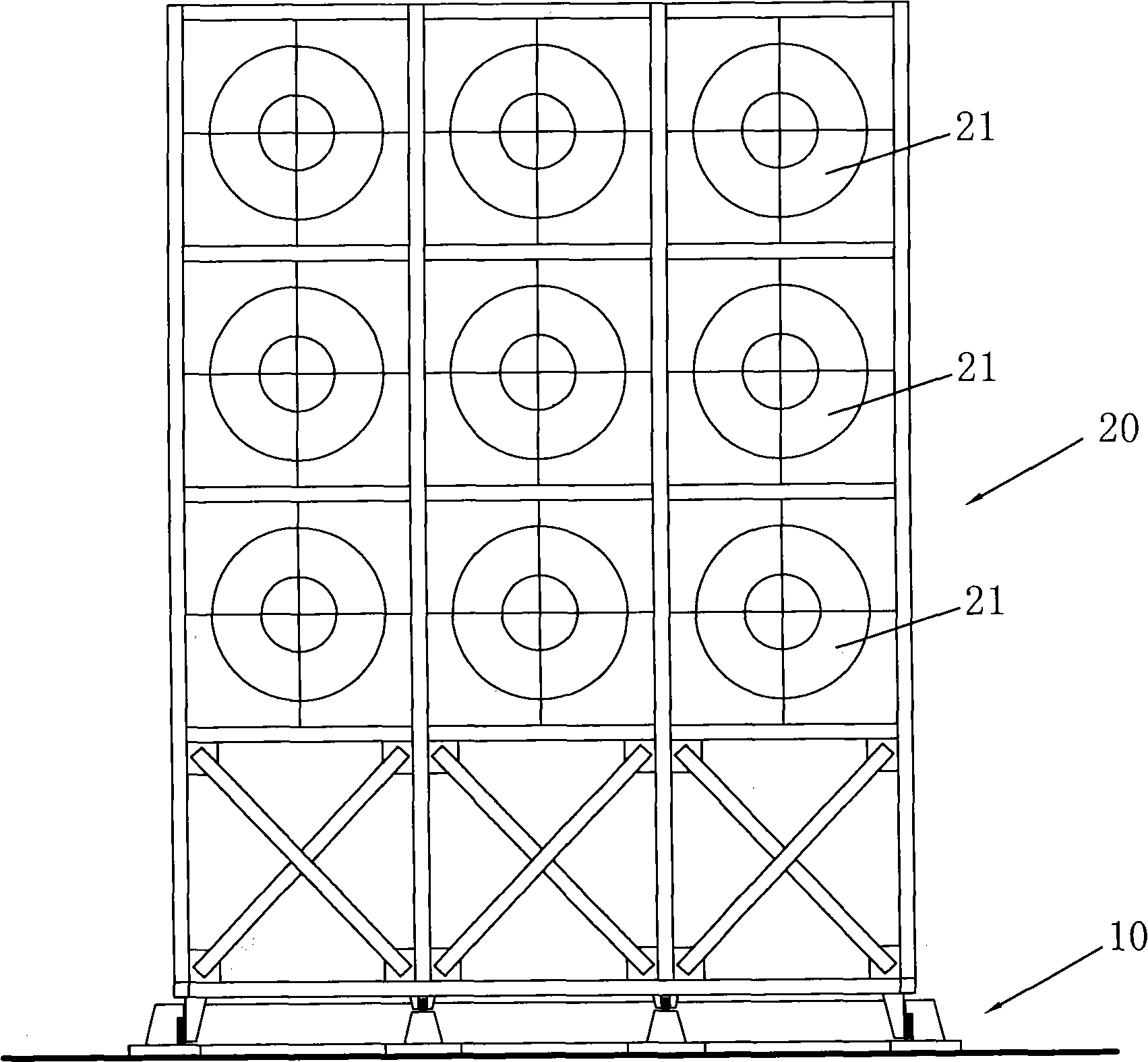

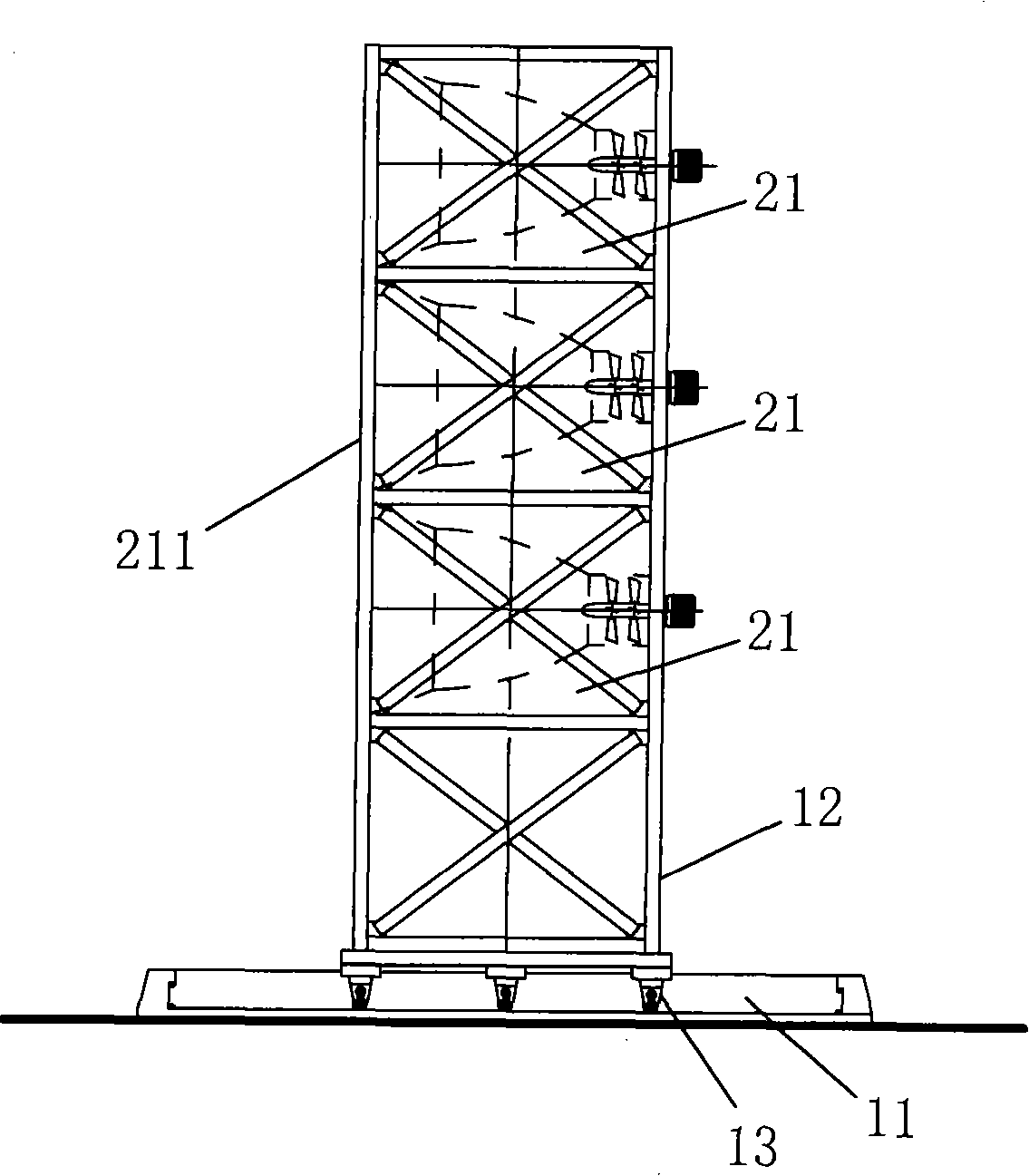

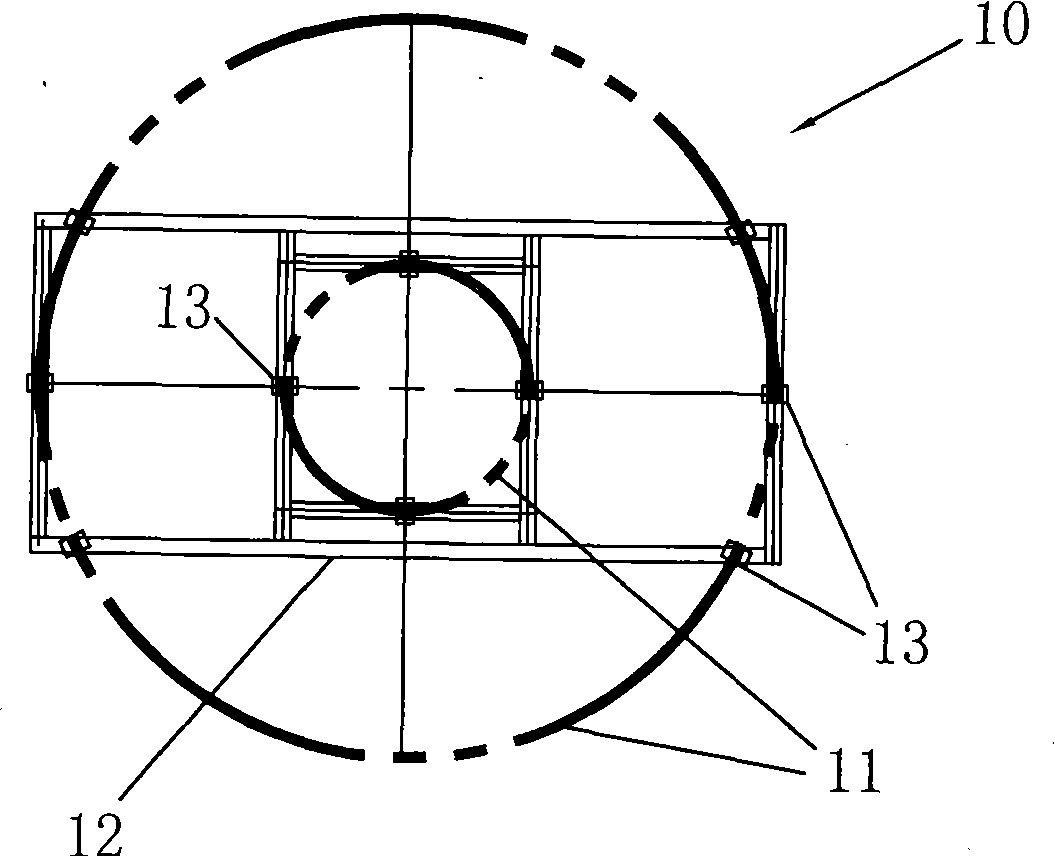

[0042] see figure 1 , figure 2 , image 3 , is a wind power generation device provided by the present invention, which includes a base 10 and a matrix wind power generation device 20 erected on the base 10, wherein:

[0043] The base body 10 includes a circular track 11 fixed on the ground and a base 12 that rotates on the circular track 11. The base 12 is also provided with a wind direction monitoring device (using the prior art) and a tracking rotary device, the wind direction monitoring device is electrically connected to the tracking and turning device, and can measure the wind direction and send it to the tracking and turning device, and the tracking and turning device receives the information provided by the wind direction monitoring device, and then controls the base 10 is rotated or positioned on the track to ensure that the windward faces of the plurality of wind power generation modules on the seat 10 are adapted to the wind direction; in this embodiment, the circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com