Vertical-shaft maglev wind-driven power generator

A technology of wind power generators and magnetic levitation, applied in wind power generators, wind power motor combinations, wind power generators at right angles to the wind direction, etc. Increase the manufacturing and operating costs of wind turbines to achieve the effect of high wind energy utilization, simple structure, and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

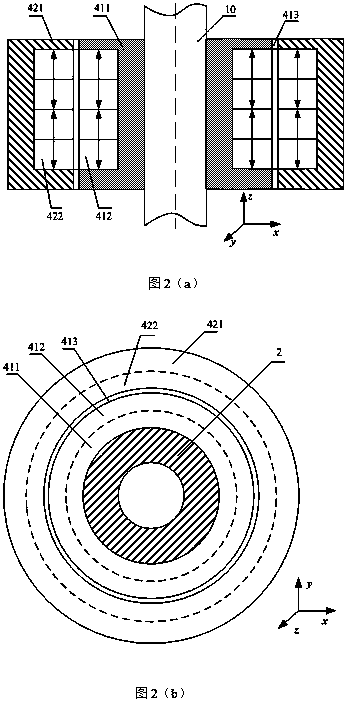

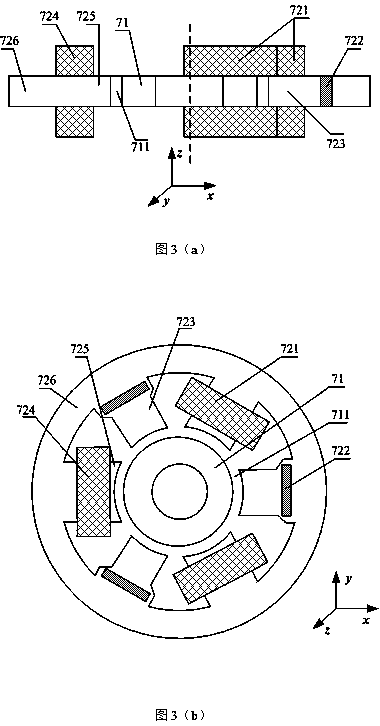

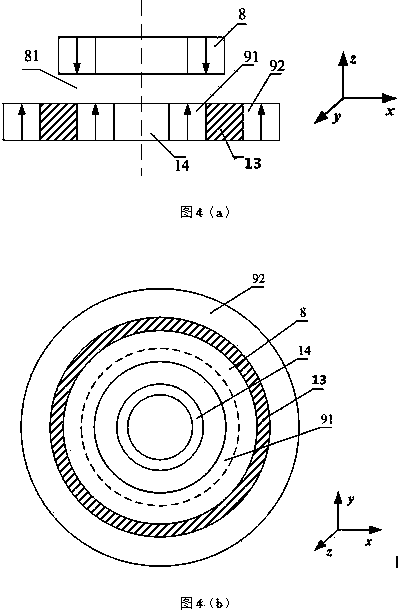

[0031] like figure 1 As shown, a vertical axis magnetic levitation wind power generator is composed of a stationary part and a rotating part, and is characterized in that the stationary part includes an upper end protection bearing 3, a static magnetic ring part 42 of a radial permanent magnetic bearing, and a generator stator from top to bottom. 62. Six-pole radial hybrid magnetic bearing stator 72, lower end protective bearing 5, inner magnetic ring 91 at the lower end of the axial permanent magnetic bearing, outer magnetic ring 92 at the lower end of the axial permanent magnetic bearing, magnetic isolation ring 13, wind turbine casing 12 and wind turbine tower 15;

[0032] The rotating part includes from top to bottom: blade 1, hub 2, wind turbine shaft 10, baffle plate 11, radial permanent magnetic bearing moving magnetic ring part 41, generator rotor 61, six-pole radial hybrid magnetic bearing rotor 71, A permanent magnet ring 8 at the upper end of the axial permanent ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com