Normally Closed Brake for Hydraulic Wet Drive Axle

A drive axle, normally closed technology, applied in the direction of hydraulic brakes, brake actuators, gear transmission mechanisms, etc., can solve the problems of vehicle brakes not working, loss of safety guarantee, unsuitable safety, etc., to facilitate processing. , Simplified structure, the effect of large braking torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

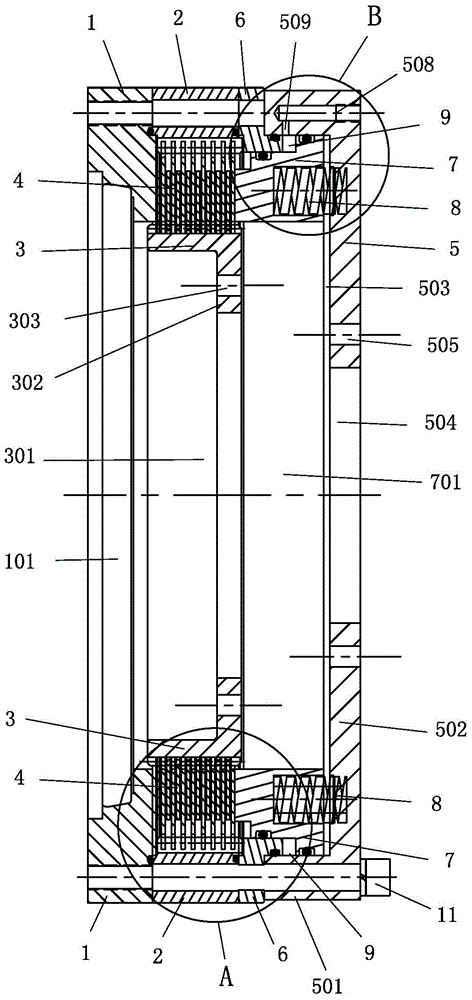

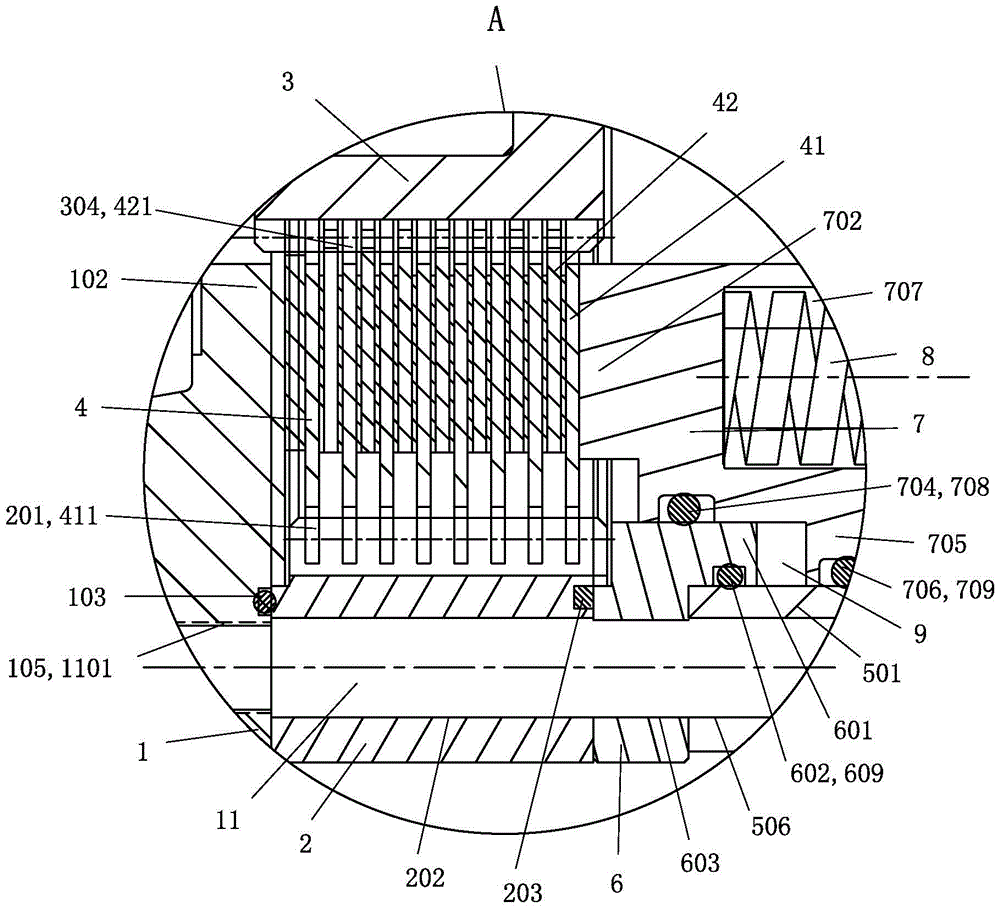

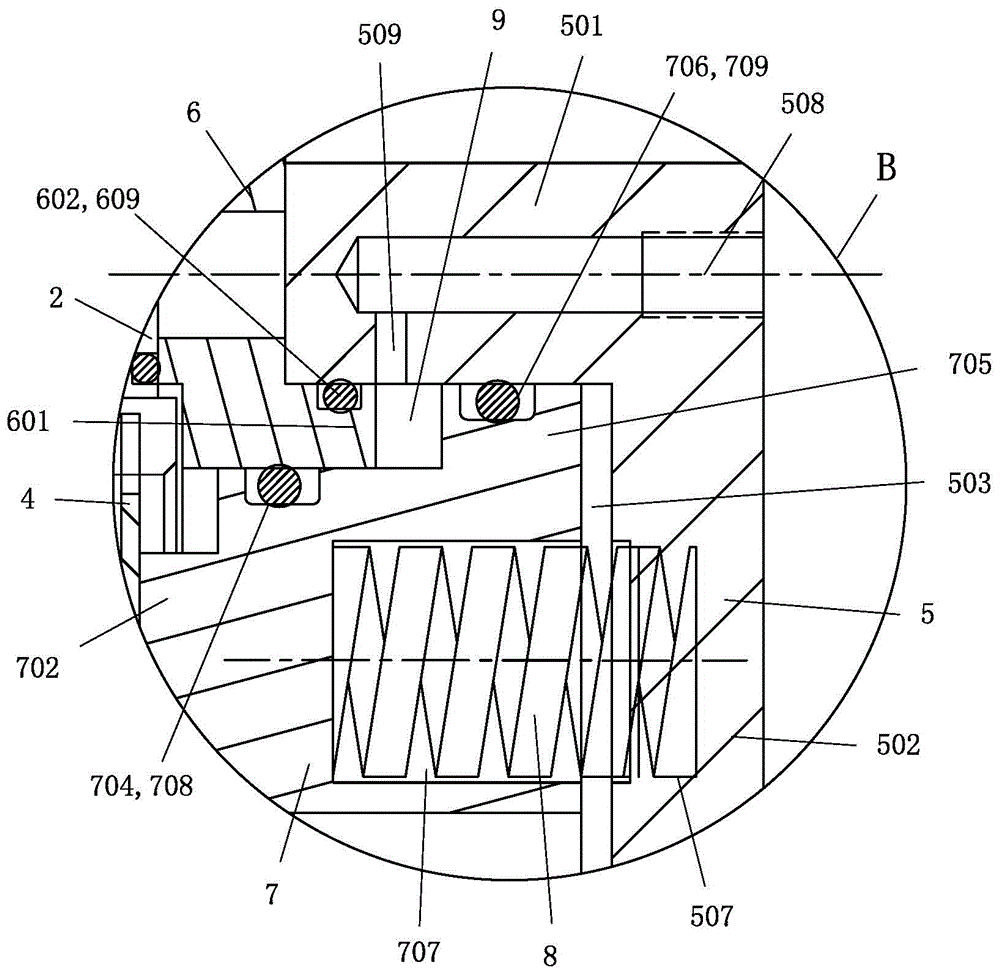

[0033] The cross-sectional structure of an embodiment of the normally closed brake for the hydraulic wet drive axle of the present invention, as figure 1 As shown, it is in the shape of a ring as a whole, and it includes a ring-shaped retaining ring 1, a ring-shaped outer ring 2, and a ring-shaped support frame formed by a ring-shaped inner ring 3 with a central hole at the bottom. Circular wet brake pad assembly 4, a circular ring composed of a circular cylinder 5 with a central hole at the bottom, a circular cylinder head 6, a circular piston 7 and multiple brake springs 8 shaped hydraulic cylinder.

[0034] The stop ring 1 and the outer ring 2 of the support frame are fixedly connected with the cylinder head 6 and the cylinder body 5 of the hydraulic cylinder sequentially from front to back to form a whole. The brake pad assembly 4 is installed between the outer ring 2 and the inner ring 3 of the support frame, and the outer circumference of all the brake pads 41 in the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com