High-efficiency aluminum alloy profile oxidation device and aluminum alloy profile grinding process

An aluminum alloy profile and oxidation device technology, applied in the direction of anodic oxidation, etc., can solve problems such as difficulty in meeting consumer demand, environmental pollution, uneven surface quality, etc., and achieve improved secondary utilization, good electrical conductivity, and improved consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

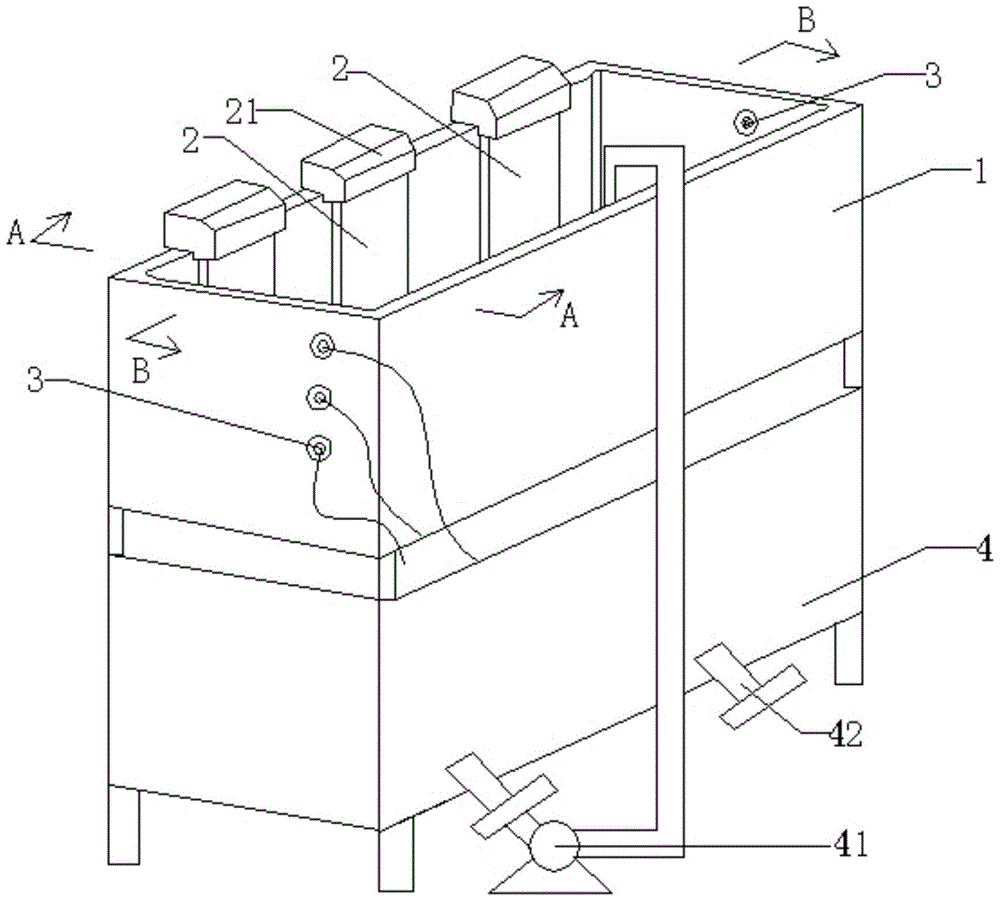

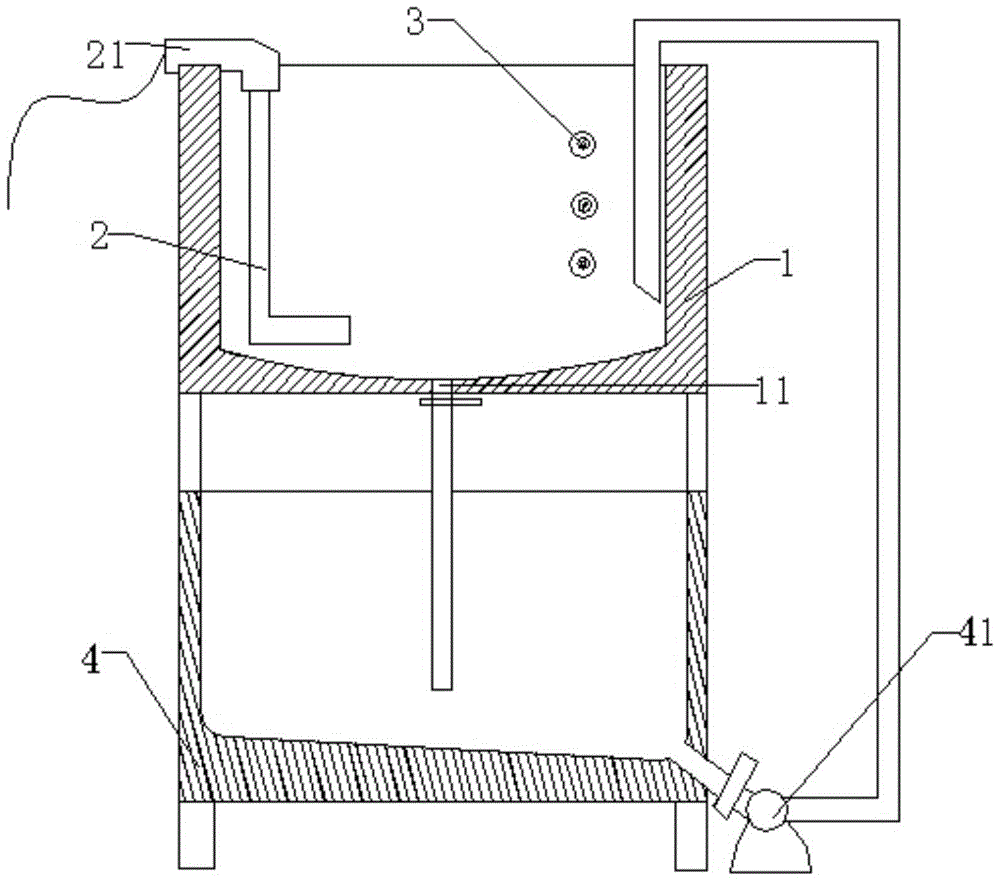

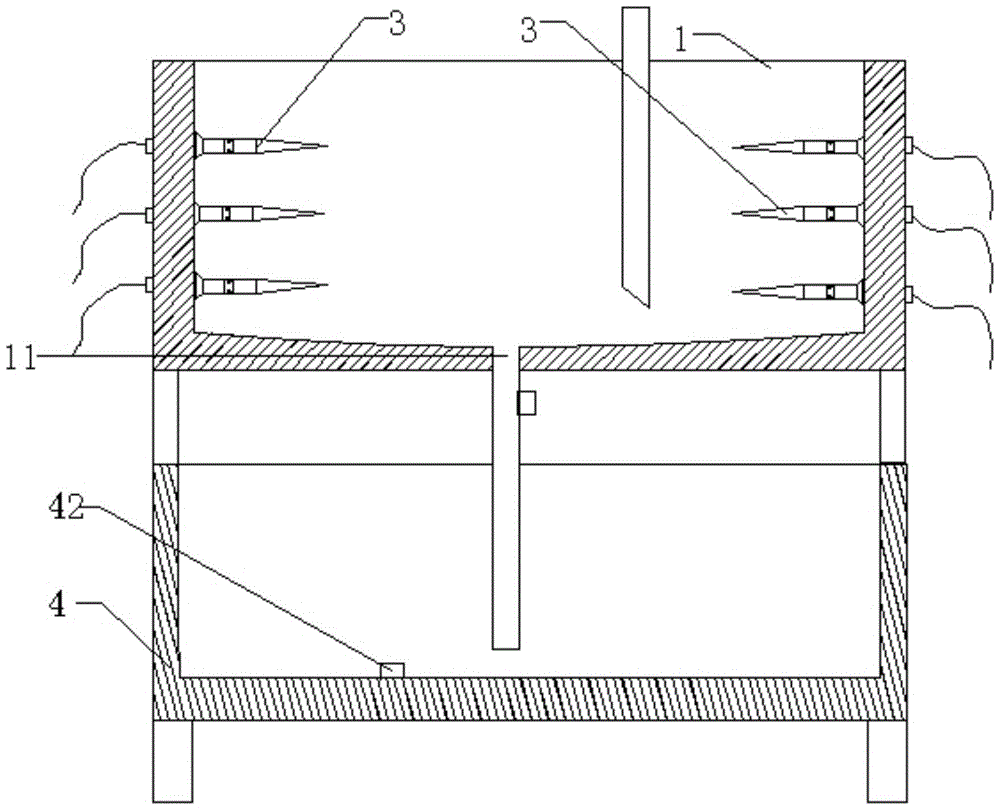

[0041] The present invention will be further described now in conjunction with accompanying drawing. These drawings are simplified schematic diagrams only to illustrate the basic structure of the present invention in a schematic way, so they only show the components relevant to the present invention.

[0042] Such as figure 1 , 2 , a high-efficiency aluminum alloy profile oxidizing device shown in 3, the anodizing device includes an electrolytic cell body 1, a cathode conductive device 2, an anode conductive device 3 and an electrolyte configuration tank 4, and the cell edge end surface of the electrolytic cell body 1 has a uniform Distributed notches, the cathode conductive device 2 is clamped with the electrolytic cell body 1 through the notches, the bottom plate section of the electrolytic cell body 1 is concave, and the center of the concave shape is vertically provided with a drain pipe 11 leading to the electrolyte configuration tank 4; The cathode conductive device 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com