Building waste treatment device for recycling building engineering waste

A construction waste and construction engineering technology, applied in the field of construction waste treatment devices, can solve the problems of low secondary utilization rate of construction waste, poor stability and reliability, and insufficient smashing, so as to improve the secondary utilization rate and economic benefits, The effect of reducing dust and avoiding health hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

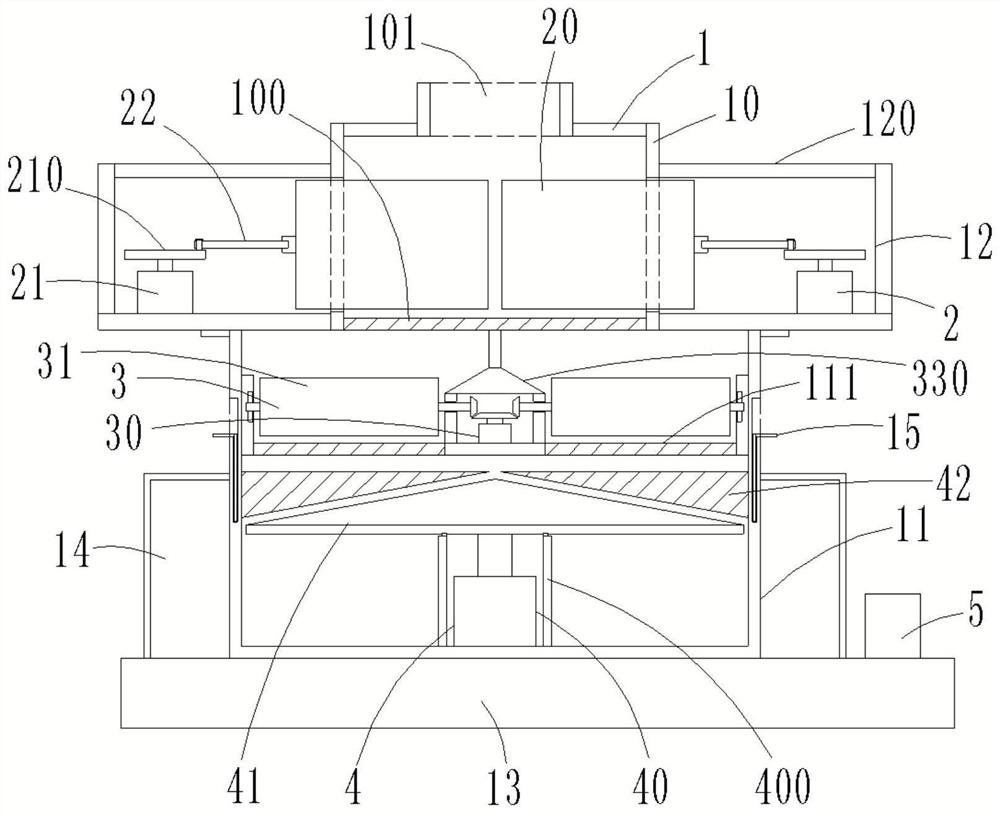

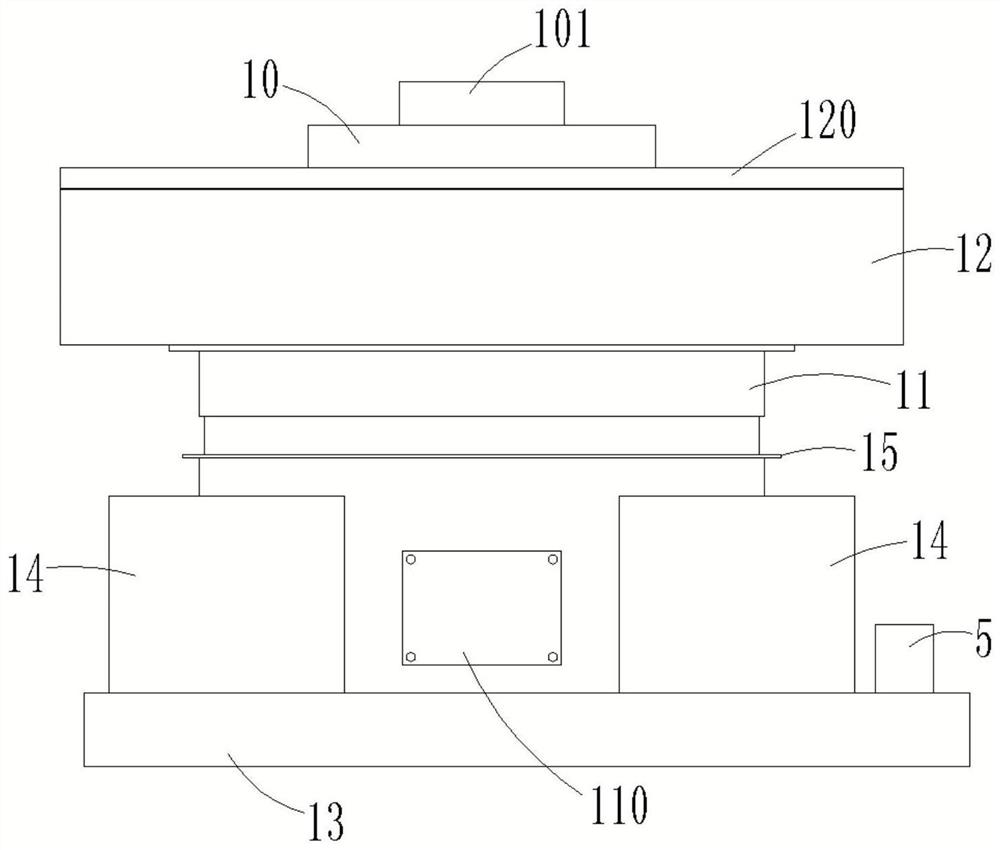

[0034] Embodiment 1: as figure 1 , 2 A construction waste treatment device for reuse of construction waste is shown, including a box body 1, a coarse crushing assembly 2 and a refinement assembly 3; the box body 1 includes a first crushing box 10 and a second crushing box 11, the first A crushing box 10 is arranged on the upper end of the second crushing box 11, and a coarse mesh screen 100 is arranged at the junction of the first crushing box 10 and the second crushing box 11, and an equipment box 12 is set outside the first crushing box 10, and the upper end is provided with a The feeding bin 101; the lower end of the second crushing box 11 is provided with a base 13, the side wall is provided with a discharge bin door 110, and the inner wall is provided with a fine mesh screen 111;

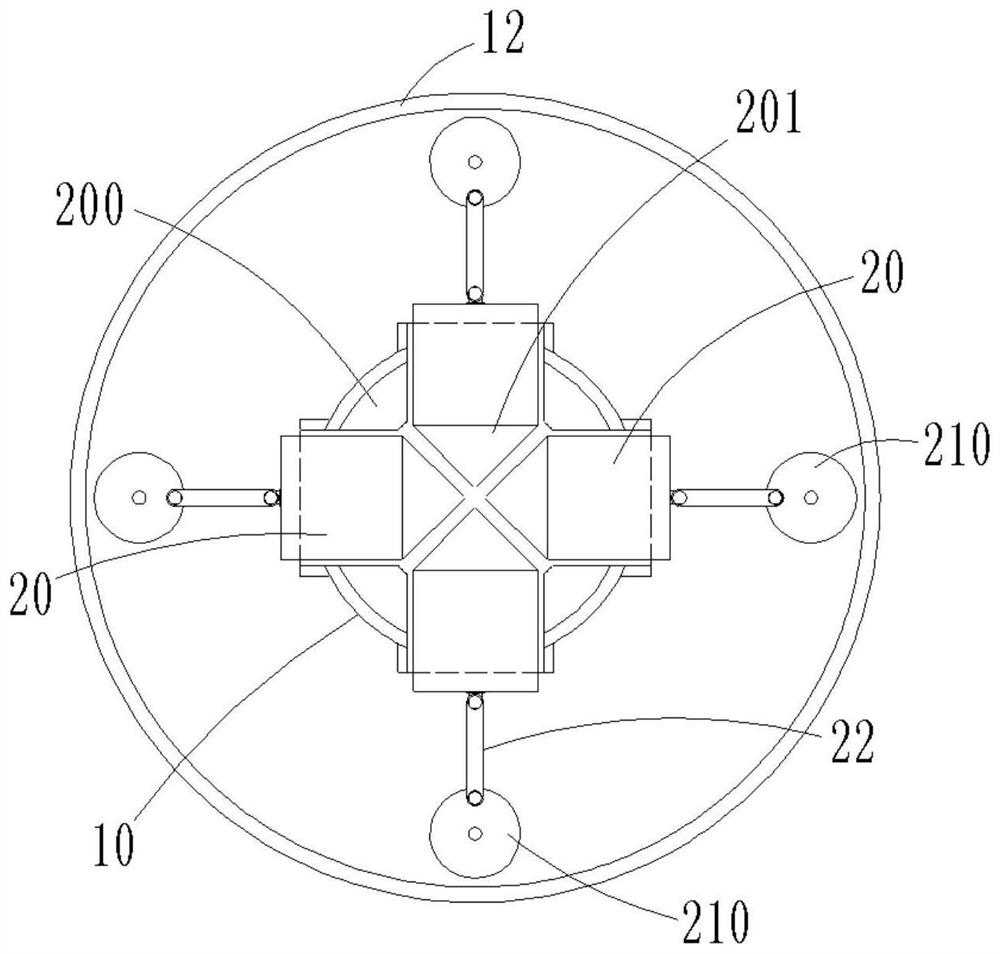

[0035] likefigure 1 , 3 , 4, the coarse crushing assembly 2 includes a crushing block 20 and a crushing motor 21, four crushing blocks 20 are provided, and the four crushing blocks 20 are eve...

Embodiment 2

[0037] Embodiment 2: as figure 1 , 2 A construction waste treatment device for reuse of construction waste is shown, including a box body 1, a coarse crushing assembly 2, a refinement assembly 3 and a screening assembly 4; the box body 1 includes a first crushing box 10 and a second crushing box 10 The crushing box 11, the first crushing box 10 is arranged on the upper end of the second crushing box 11, and the connection between the first crushing box 10 and the second crushing box 11 is provided with a coarse mesh screen 100, and the first crushing box 10 is equipped with an equipment box 12. The upper end is provided with a feed bin 101; the lower end of the second crushing box 11 is provided with a base 13, the side wall is provided with a discharge bin door 110, and the inner wall is provided with a fine mesh screen 111; the base is provided with a dust removal fan 5, a dust removal fan 5. The first crushing box 10 and the second crushing box 11 are respectively connecte...

Embodiment 3

[0041] Embodiment 3: as figure 1 , 2 A construction waste treatment device for reuse of construction waste is shown, including a box body 1, a coarse crushing assembly 2, a refinement assembly 3 and a screening assembly 4; the box body 1 includes a first crushing box 10 and a second crushing box 10 The crushing box 11, the first crushing box 10 is arranged on the upper end of the second crushing box 11, and the connection between the first crushing box 10 and the second crushing box 11 is provided with a coarse mesh screen 100, and the first crushing box 10 is equipped with an equipment box 12. The upper end of the equipment box 12 is movably clamped with an end cover 120. By setting the end cover 120, it is convenient to replace and maintain the internal parts of the equipment box 12, and to improve the reliability of the device; the upper end of the first crushing box 10 is provided with a feed bin 101 The second pulverizing case 11 lower end is provided with base 13, is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com