Cutting machine for cutting lower hems of skirts

A cutting machine and skirt technology, which is used in the cutting of textile materials, tools for sewing clothes, textiles and papermaking, etc., can solve problems such as low efficiency, and achieve the effect of flexible height adjustment and strict uniform skirt length.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below with reference to the drawings and embodiments:

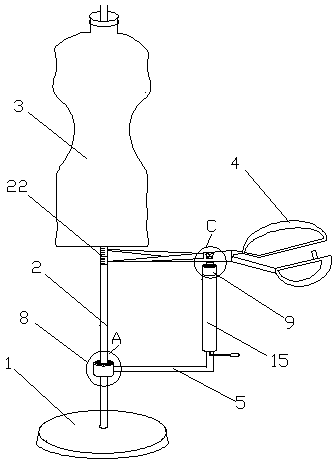

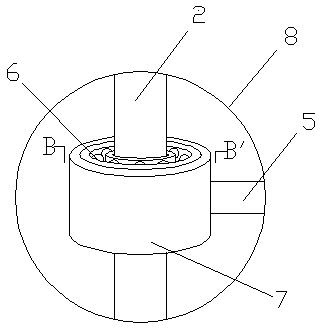

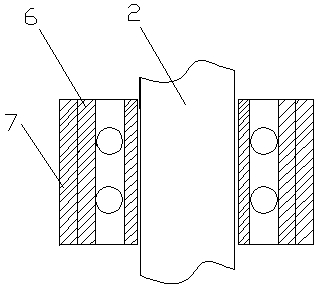

[0030] By the attachment figure 1 , Attached figure 2 , Attached image 3 , Attached Figure 4 And Figure 5 It can be seen that a cutting machine for cutting the hem of a skirt includes a base 1, a support rod 2, a hanger 3, and a cutting knife 4. The support rod 2 is fixedly installed on the base 1, and the support rod 2 The upper end is provided with a hanger 3, the cutting knife 4 is provided with a connecting rod 5, the connecting rod 5 is rotatably connected to the support rod 2 through a bearing 8. The bearing 8 includes a bearing body 6 and a bearing sleeve 7, and the bearing body 6 is sleeved on the support rod 2, and the bearing sleeve 7 is welded to the connecting rod 5; the cutting knife 4 is connected to the connecting rod 5 through the auxiliary bearing 9, and the auxiliary bearing 9 includes an auxiliary bearing body 10, an auxiliary bearing sleeve 11 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com