Adjustable dust-suction nozzle wheel

A vacuum nozzle and adjustable technology, which is applied in the field of vacuum nozzle wheel devices, can solve complex and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

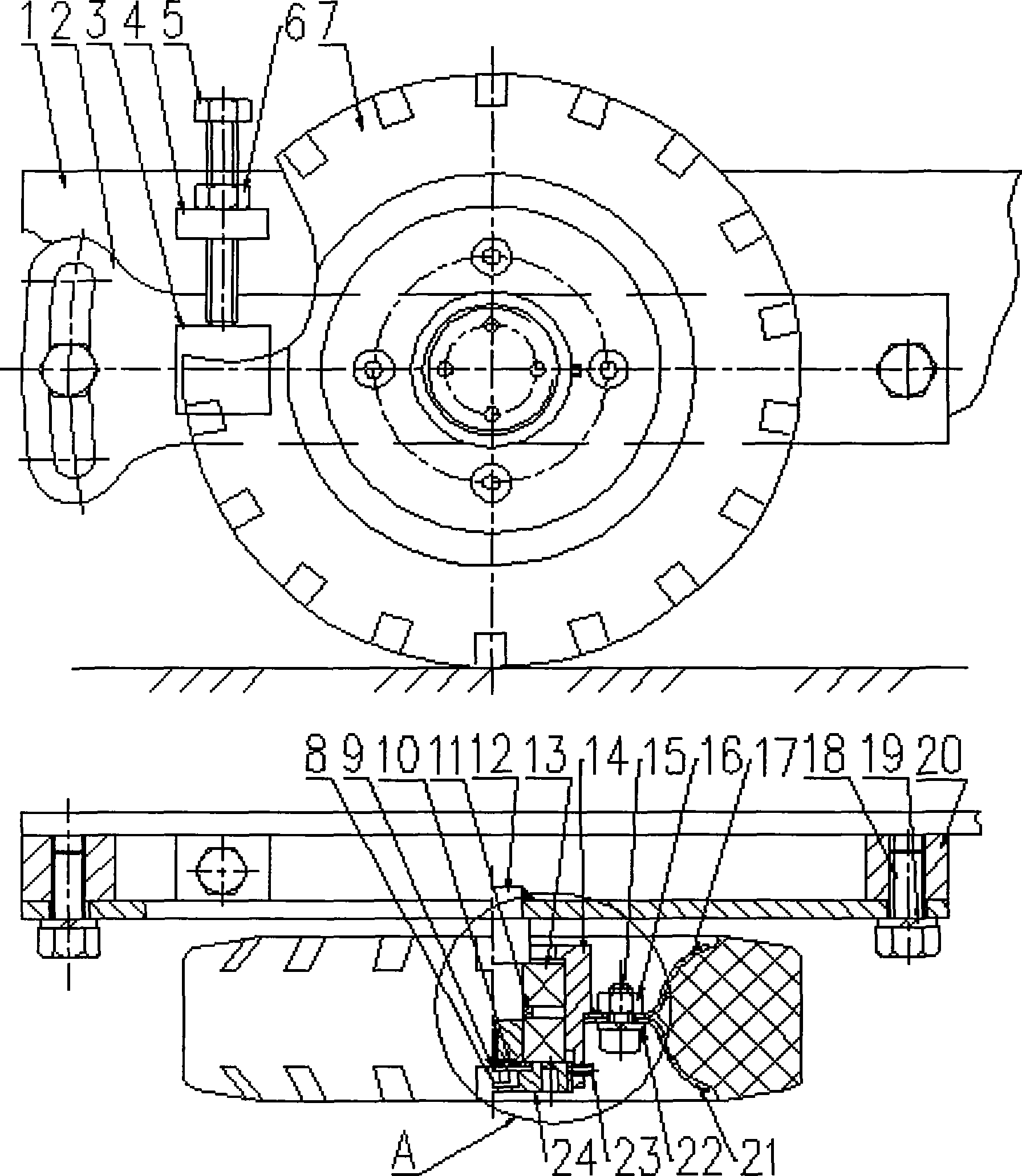

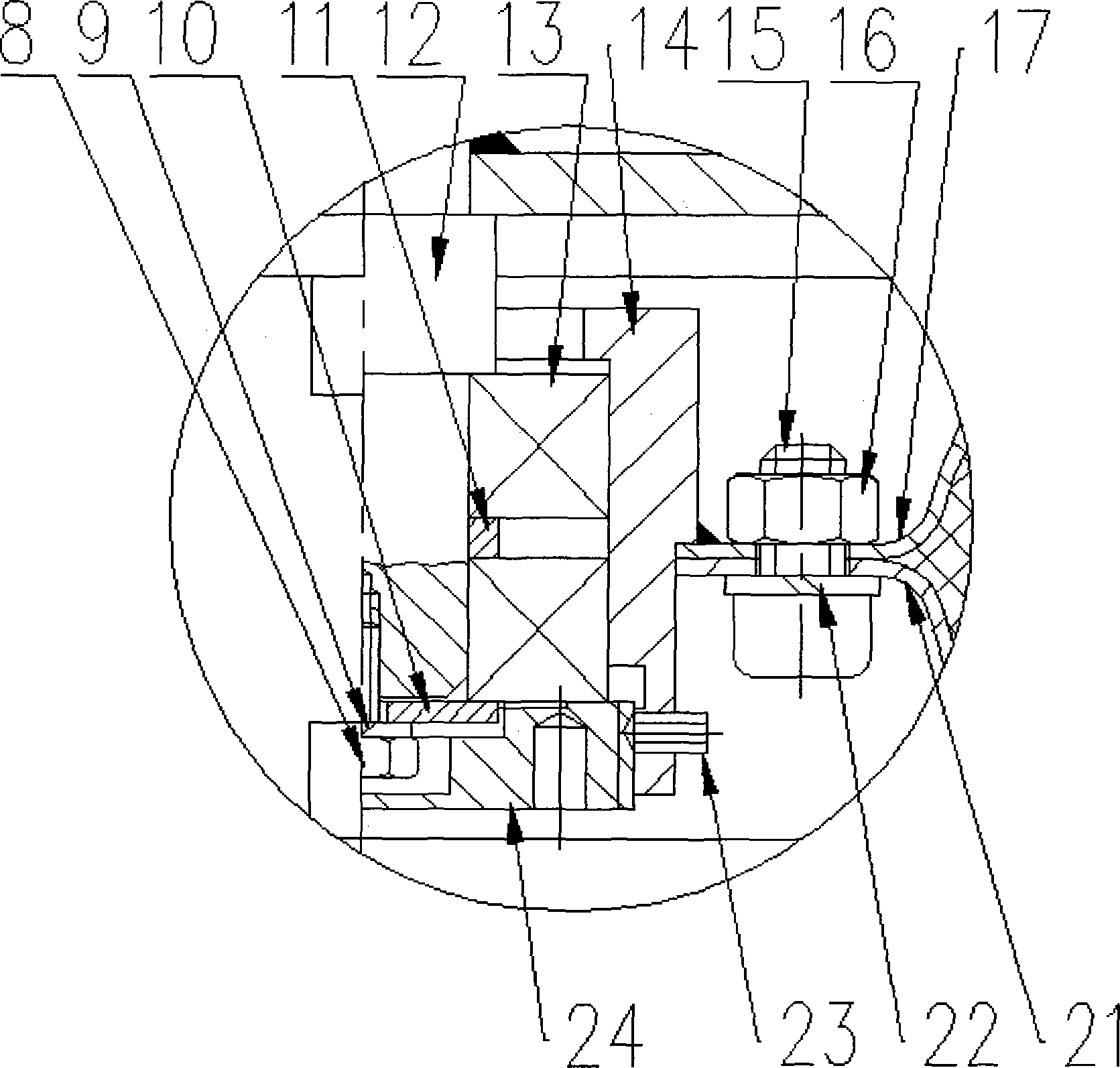

[0011] Embodiments of the present invention will be further described below with reference to the accompanying drawings:

[0012] As shown in the figure, a nozzle-adjustable wheel includes a side connecting plate 1, a wheel arm 2, a bracket 3, a lock plate 4, a limit bolt 5, a limit nut 6, a rubber wheel 7, a fixing screw 8, Fixed washer 9, baffle plate 10, liner 11, axle 12, bearing 13, wheel cover 14, screw 15, nut 16, rim plate one 17, connecting screw 18, connecting washer 19, connecting seat 20, rim plate two 21, Washer 22, locking screw 23, end cap 24, the side connection plate 1 is welded and fixed with the connection seat 20 and the lock plate 4, which belongs to the suction nozzle device, the wheel arm 2 is welded with the wheel shaft 12 and the bracket 3, and Fixed on the connecting seat 20 by connecting screws 18 and connecting washers 19, the wheel cover 14 is welded to the rim plate one 17, and the rubber wheel 7 is fixed by the screw 15, the nut 16, the washer 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com