Concrete baffle with corner protection side

A concrete and baffle technology, which is applied to floors, building components, buildings, etc., can solve the problems of ground boundary damage of cast-in-place concrete floors, and the concrete cannot be perfectly formed, so as to achieve good reinforcement and protection, convenient construction, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

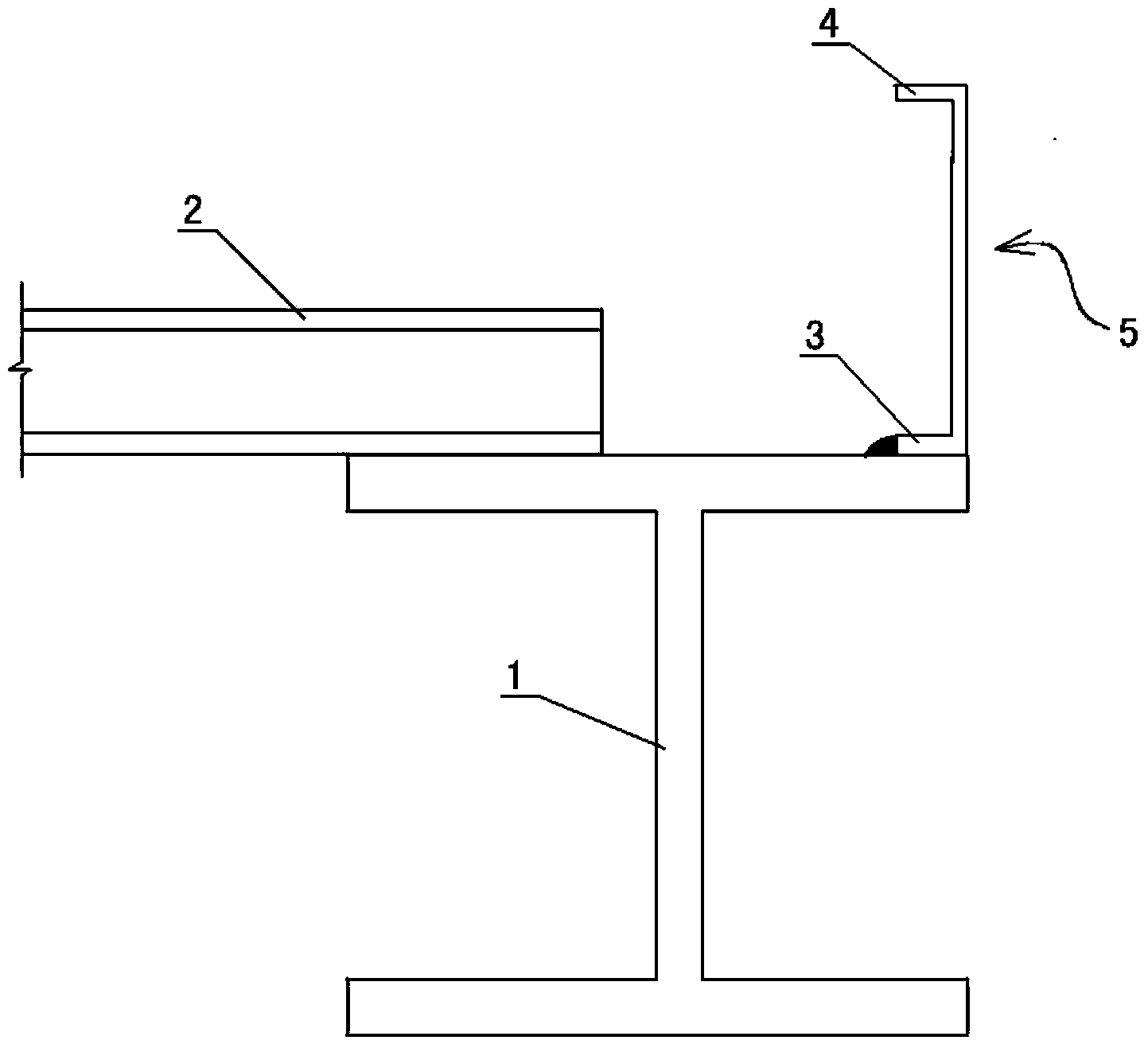

[0015] see figure 1 , the structural form of the concrete baffle with corner guards in this embodiment is:

[0016] On the outer side of the top surface of the upper flange plate of the steel beam 1, a concrete baffle 5 is arranged along the installation direction of the steel beam 1. The cross section of the concrete baffle 5 is an upright rectangular half-frame structure, and the rectangular half-frame structure is It consists of a single-side upper edge plate 4, a single-side lower edge plate 3, and a web connected between the single-side upper edge plate 4 and the single-side lower edge plate 3. The opening of the rectangular half-frame faces the side where the floor deck 2 is located. side; fixed connection between the one-sided lower edge plate 3 in the concrete baffle 5 and the steel beam 1, the height of the cast-in-place concrete is equal to that of the upper edge plate 4 in the concrete baffle 5, and the concrete baffle 5 avoids leakage The slurry can make the concr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com