Receiving device for conveying concrete

A material receiving device and concrete technology, which is applied in the processing of building materials, construction, building structure, etc., can solve the problems of large impact, falling objects from high altitude, reducing the pouring speed of parapet walls, etc., and achieve the effect of saving use and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

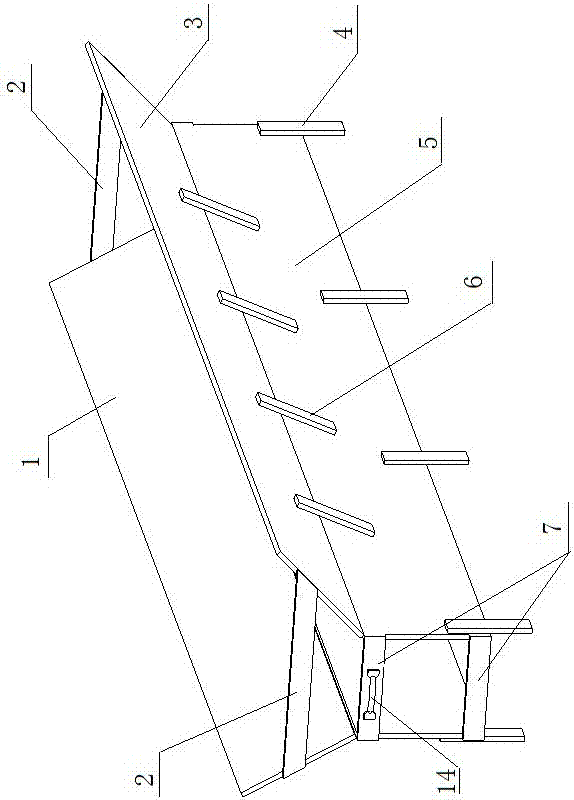

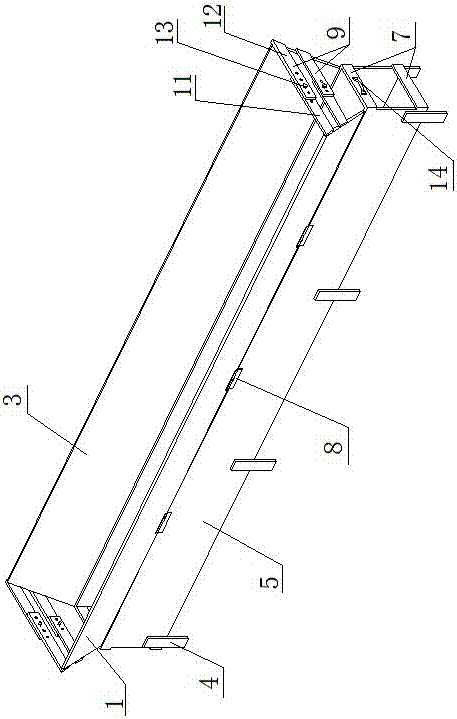

[0013] Such as figure 1 Shown embodiment 1, present embodiment comprises two vertical formworks 5, two oblique formworks 1,3, two groups of every group two (also can be three, four etc.) fixed and fastened form columns 7 (also But two fastening formworks), two groups of every group one (also can be two, three etc.) fixed tension formwork 2. The lower openings of the two vertical formworks 5 match the concrete entrances of the pouring wall formwork, and are clamped and fixed on the concrete entrance of the pouring wall formwork. The oblique template 3 at the operating end and the vertical template 5 below it are fixed on the upper end of the vertical template 5 at an angle of 30-45°, and the oblique template 1 at the other end and the vertical template 5 below it are fixed at an angle of 45-60°. Be fixed on this vertical template 5 upper ends....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com