Overhanging type cast-in-place concrete steel baffle with corner protection side

A technology of concrete and steel baffles, which is applied in the fields of formwork/formwork/work frame, on-site preparation of building components, construction, etc., can solve the problems of imperfect concrete formation, damage to the ground boundary of cast-in-place concrete buildings, etc., to achieve convenient The effect of construction, increased utilization, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

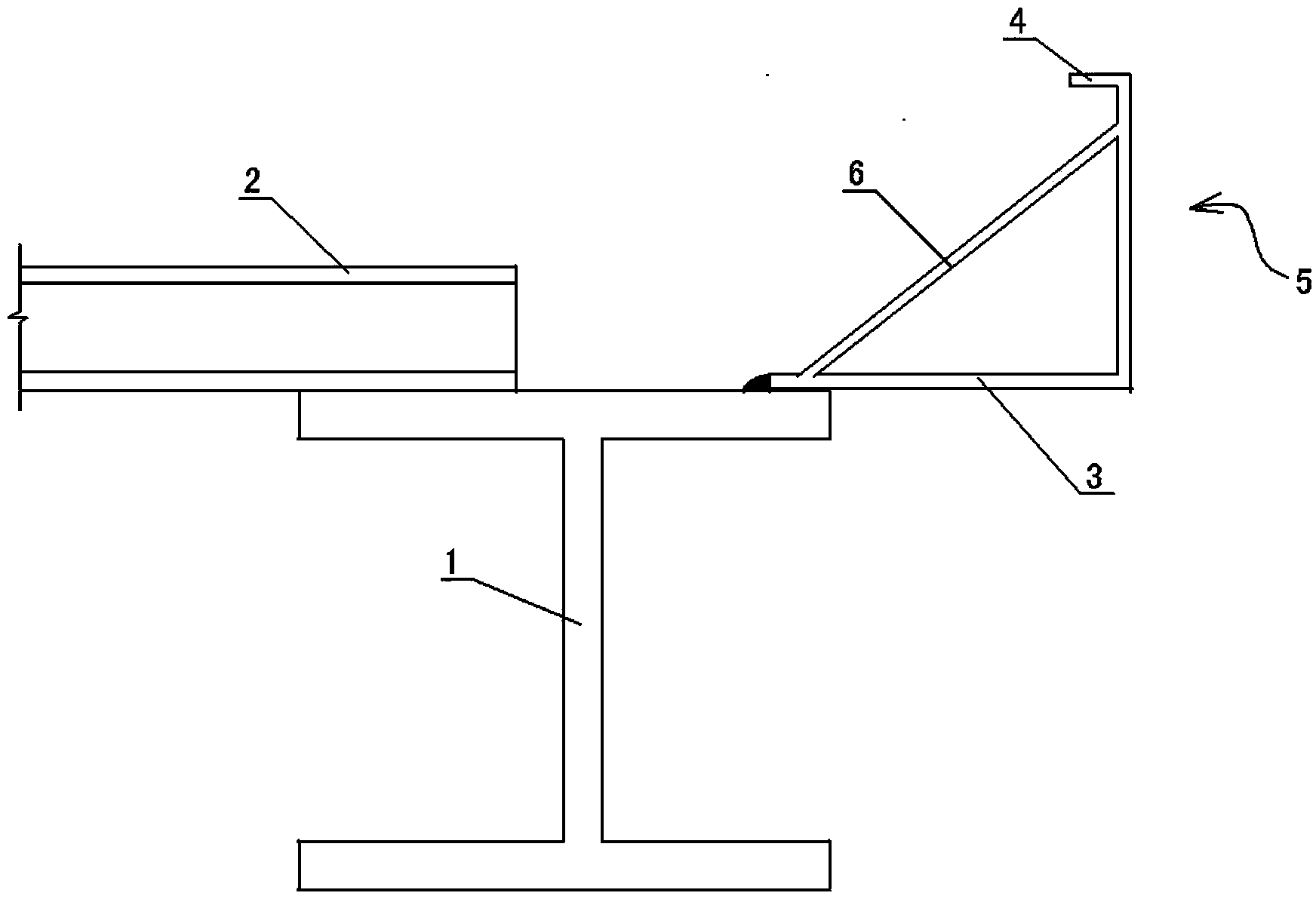

[0019] see figure 1 In this embodiment, the structural form of the cantilevered cast-in-place concrete steel baffle with corner guards is: along the installation direction of the steel beam 1, on the outer side of the top surface of the upper flange plate of the steel beam 1 to hang The concrete baffle 5 protruding from the outside of the steel beam is set in the form of a cantilever. The cross section of the concrete baffle 5 is an upright rectangular half-frame structure. 3, and the web connected between the single-side upper edge plate 4 and the single-side lower edge plate 3, the opening of the rectangular half-frame faces the side where the floor deck 2 is located; the single-side lower edge of the concrete baffle 5 The plate 3 is fixedly connected to the steel beam 1, and the height of the cast-in-place concrete is equal to that of the upper edge plate 4 in the concrete baffle 5. The concrete baffle 5 avoids grout leakage, and makes the concrete boundary perfectly formed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com