Gear ring structure of speed reducer

A technology of reducer and ring gear, applied in mechanical equipment, components with teeth, belts/chains/gears, etc., can solve the problems of increased maintenance frequency, damage, increased lubricant consumption, etc., and achieves low operating costs, sealing good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

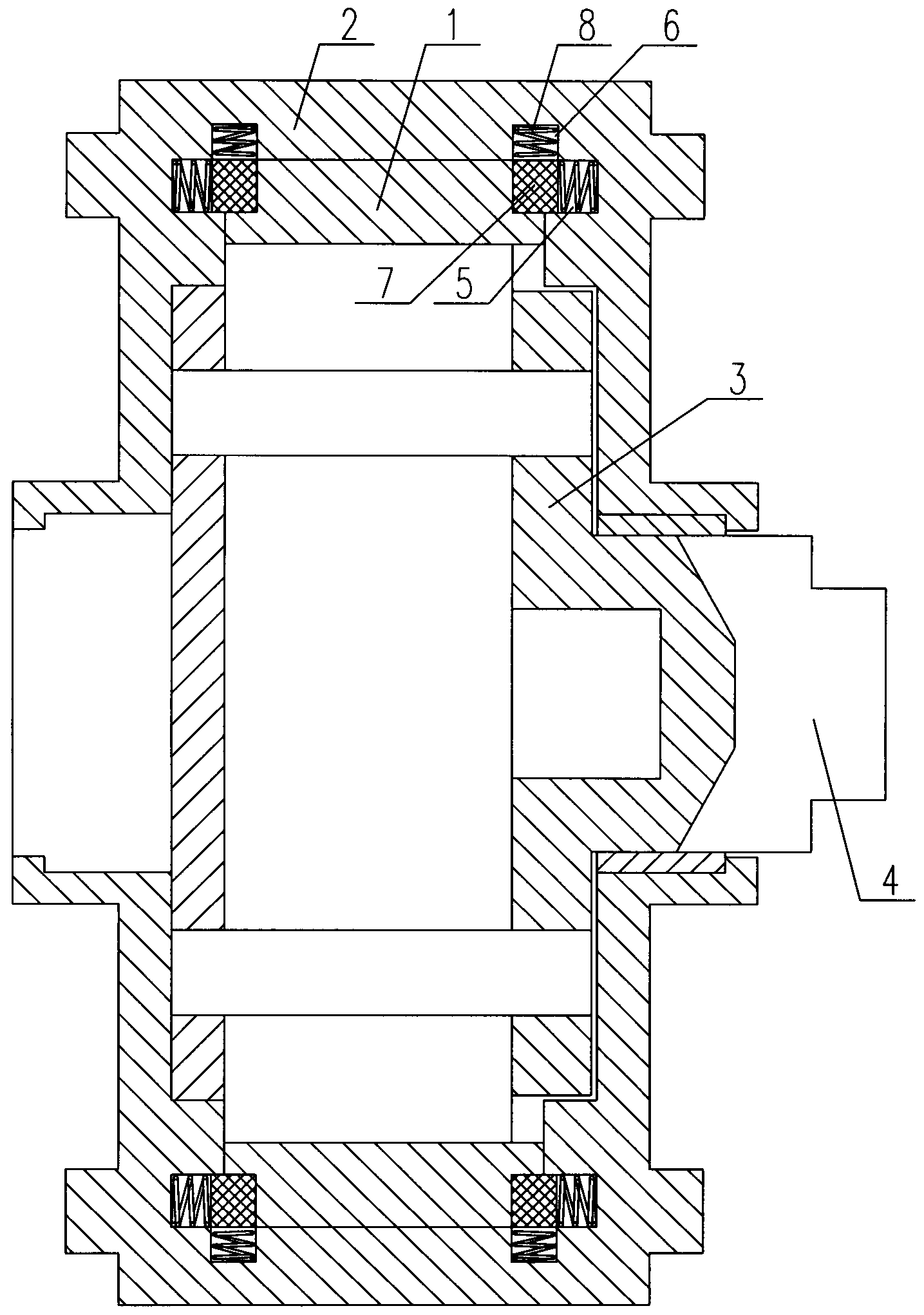

[0008] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0009] like figure 1 As shown, the ring gear structure of the reducer includes: a reduction ring gear 1 and a reduction ring gear cover 2 cooperating with the reduction ring gear 1, a planet carrier 3 and a sun gear shaft 4 are arranged in the reduction ring gear 1, and the The inner two ends of the deceleration ring gear cover 2 are respectively provided with a transverse annular sealing chamber 5 and a longitudinal annular sealing chamber 6, and at the staggered positions of the transverse annular sealing chamber 5 and the longitudinal annular sealing chamber 6, there are The rubber pads 7 that cooperate with each other are respectively provided with springs 8 in the transverse annular sealing chamber 5 and the longitudinal annular sealing chamber 6, one end of the spring 8 is against the deceleration ring gear 1, an...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap