Support frame for petroleum pipelines with various diameters

A support frame and oil pipe technology, applied in the direction of pipe supports, pipes/pipe joints/fittings, mechanical equipment, etc., to achieve stable installation, simple structure, and good support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

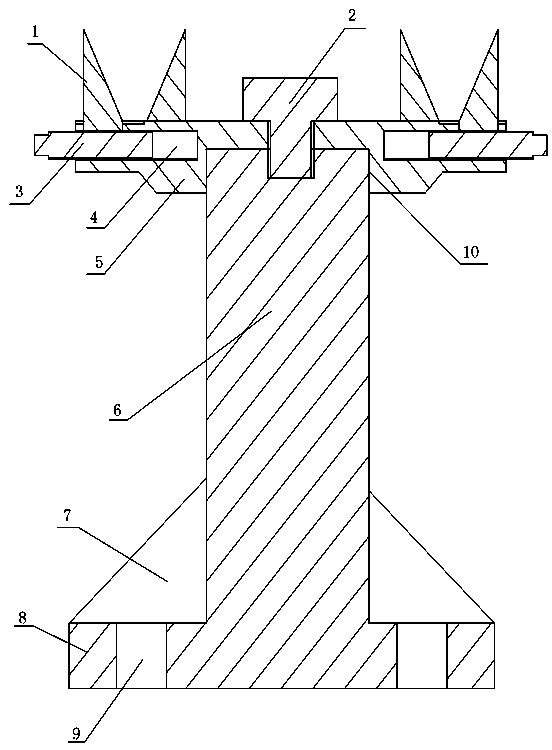

[0015] Such as figure 1 The shown oil pipe support frame for various diameters includes a support seat 6 and an oil pipe holder 5 fitted on the upper end of the support seat 6. The support seat 6 includes a cylindrical column, and the lower end of the column forms a fixed base 8 , the fixed base 8 is provided with a positioning through hole 9; the lower end of the oil pipe holder 5 forms a collar, and the middle part of the collar is provided with a positioning groove 10, and the oil pipe holder 5 is sleeved on the upper end of the support seat 6 through the positioning groove 10, so that Both sides of the upper end of the tubing holder 5 are provided with a pair of triangular clamps 1, and there is a gap for placing the tubing between any pair of triangular clamps 1, and horizontal threaded holes 4 are provided on both sides of the tubing holder 5, The internal thread of the horizontal threaded hole 4 is matched with a threaded rod 3, and the lower ends of the outer triangula...

Embodiment 2

[0019] In this embodiment, a fixing screw is added on the basis of the embodiment 1, specifically: it also includes a fixing screw 2, and the fixing screw 2 passes through the middle part of the tubing holder 5 and is threadedly connected with the middle part of the upper end of the cylinder.

[0020] In this embodiment, in order to further increase the stability of the oil pipe holder 5 and ensure its long-term use and firm positioning, a fixing screw 2 is specially added. After the seat 5 is positioned, it can be fixed by the fixing screw 2 to ensure that the triangular clamp 1 is evenly stressed when the tubing clip 5 is supporting the tubing, thereby increasing the overall service life.

Embodiment 3

[0022] In this embodiment, the following structure is added on the basis of embodiment 1 or embodiment 2: two ribs 7 are evenly arranged between the fixed base 8 and the cylinder.

[0023] In this embodiment, considering that the support strength of the fixed base 8 to the tubing holder 5 and the tubing needs to meet certain requirements, and in order to ensure that the column of the fixed base 8 will not bend during long-term use and can remain vertical, the fixed Two ribs 7 are evenly arranged between the base 8 and the column, and the strength of the connection between the two is strengthened through the ribs 7 to ensure that the two are perpendicular to each other, and the strength of the entire supporting device is enhanced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com