Height adjusting device for optical detection

A height adjustment device and optical detection technology, applied in the direction of supporting machines, mechanical equipment, machines/stands, etc., can solve the problems of increasing the labor intensity of operators, and achieve the effect of improving smooth running, smooth running and good balance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

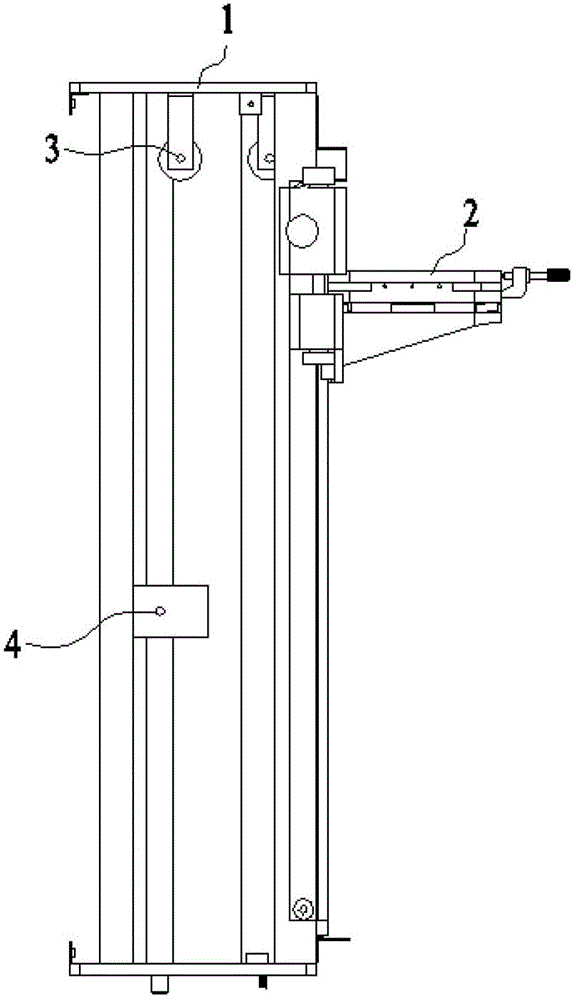

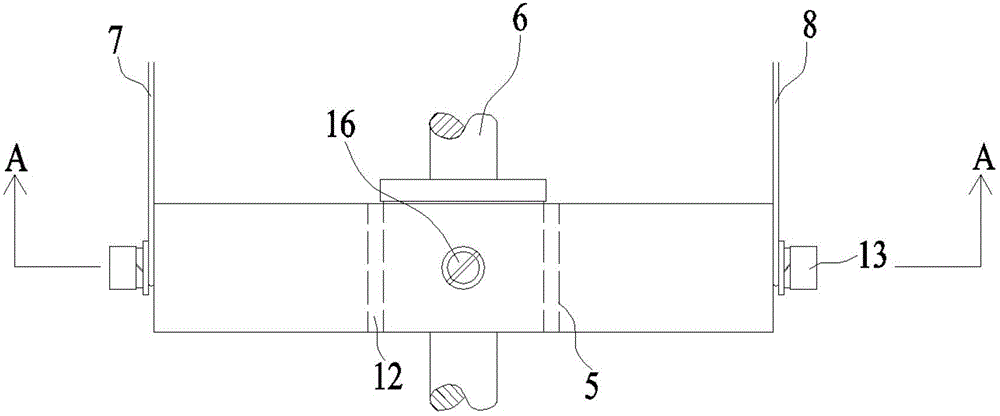

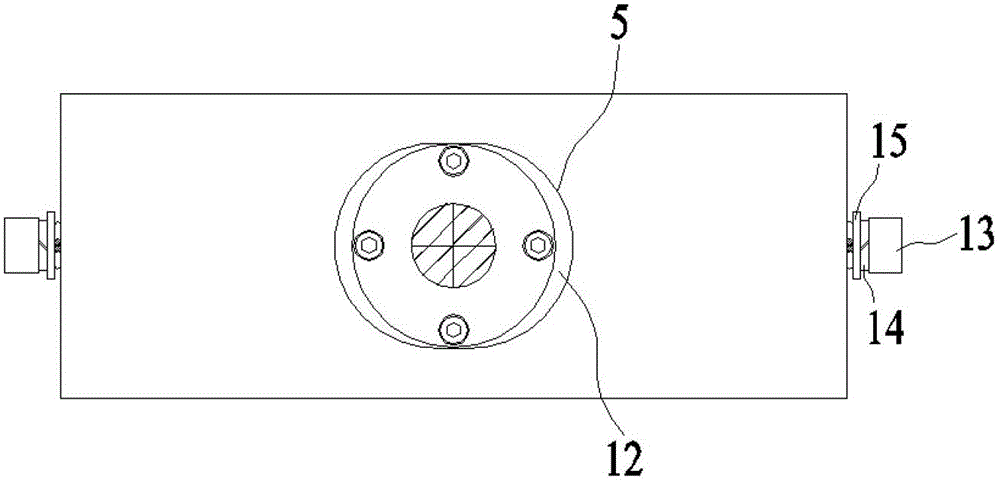

[0017] Embodiment: A height adjustment device for optical detection, comprising: a detection frame body 1, a detection platform 2 located in front of the detection frame body 1 and installed on a guide rail, a pulley block 3 located on the upper part of the detection frame body 1, and a detection platform located on the detection frame body 1. The center of the back has a counterweight 4 with a through hole 5; the through hole 5 of the counterweight 4 is embedded in a straight rod 6, and the two ends of the counterweight 4 are respectively connected to one end of the first and second steel wire ropes 7 and 8, The other ends of the first and second wire ropes 7 and 8 are connected to both ends of the detection platform 2 via the pulley block 3;

[0018] There is a linear bearing 9 between the through hole 5 of the counterweight 4 and the straight rod 6, and the linear bearing 9 can move up and down along the straight rod 6, and the moving block 91 of the linear bearing 9 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com