An online oil wear particle monitoring sensor and its manufacturing method

A technology for monitoring sensors and oil abrasive particles, applied in instruments, measuring devices, scientific instruments, etc., can solve problems such as affecting detection accuracy, fine oil pipelines, and random changes in abrasive particles, and achieve the effect of improving detection resolution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the purpose, technical solution and advantages of the present invention clearer, the implementation manners of the present invention will be further described in detail below.

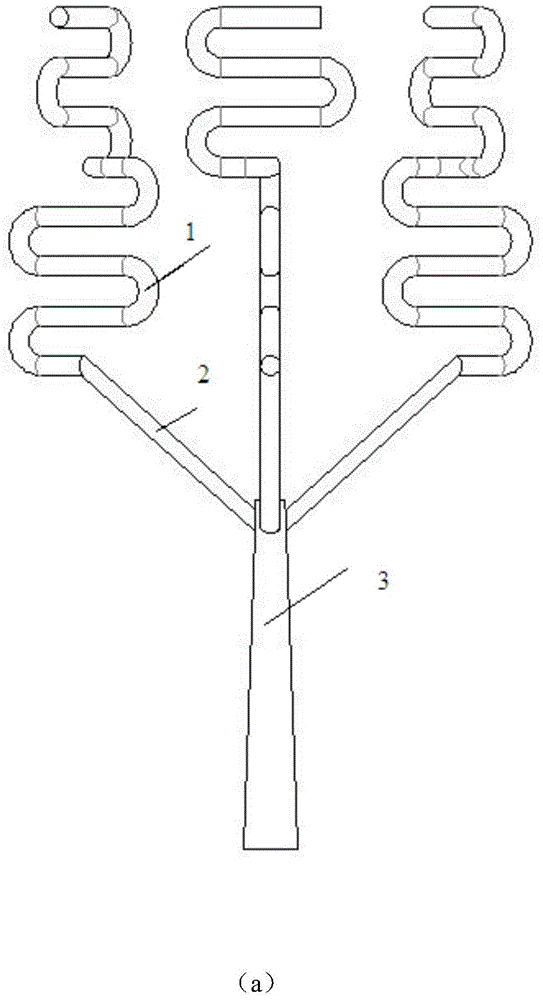

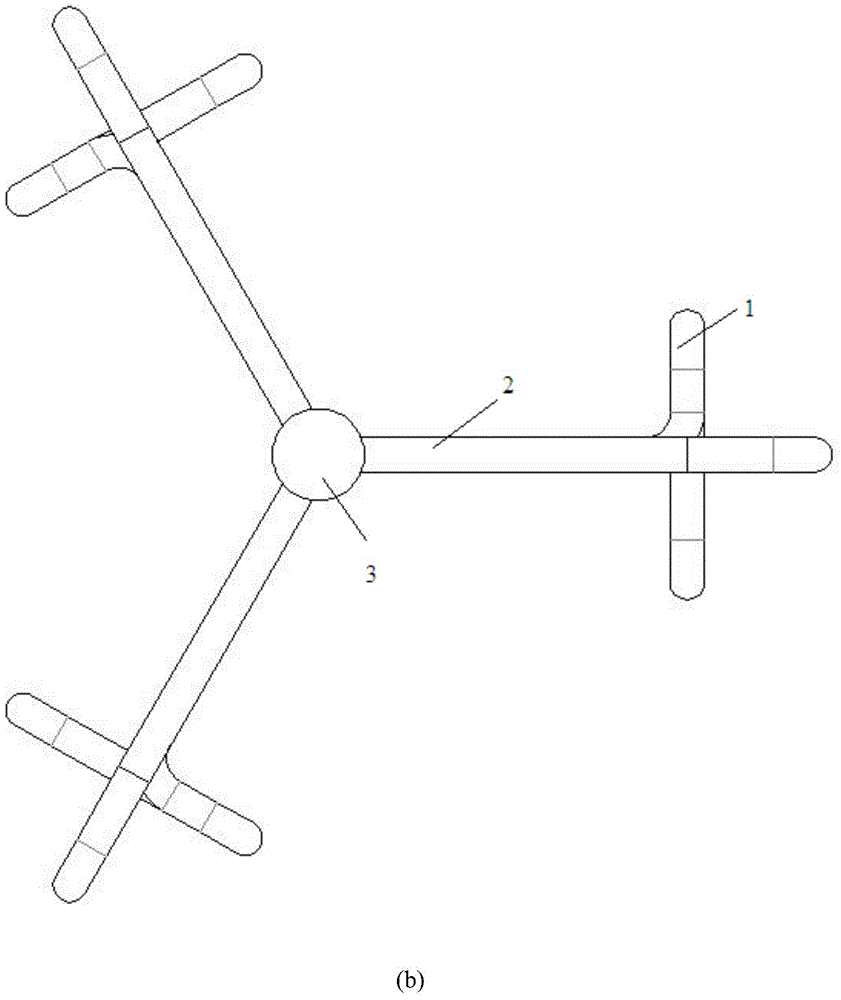

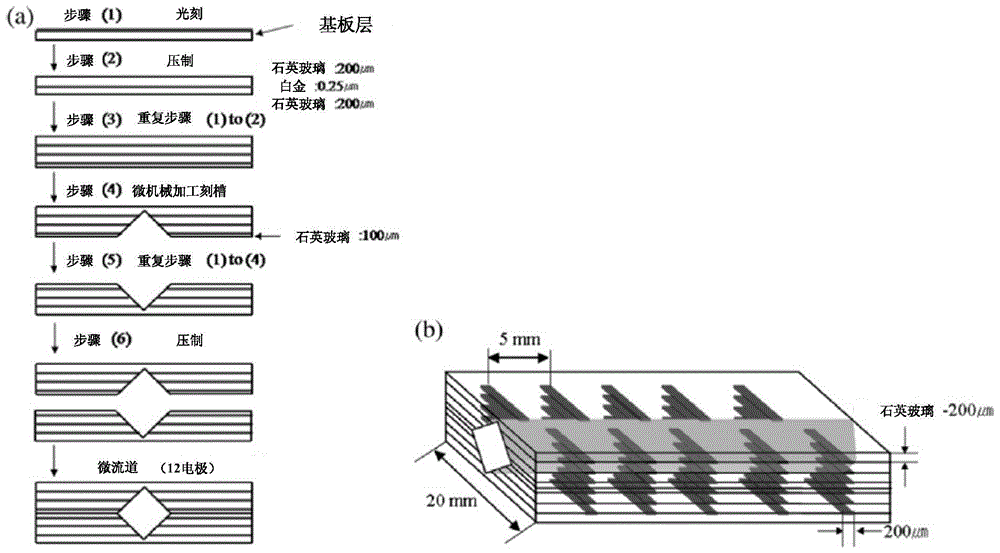

[0029] In order to achieve the design purpose, the present invention draws on the ideas of automobile engine intake and exhaust manifolds. A manifold is a pipeline divided into multiple roots, and the most common ones are automobile engine intake and exhaust manifolds. The exhaust manifold is connected to the engine cylinder block and has divergent pipelines. The exhaust manifold gathers the exhaust from each cylinder and guides it into the exhaust manifold. For this reason, the present invention divides the main pipeline of the sensor into several thin tubes in the abrasive particle detection pipe section, and each thin tube has a sensor. In this way, the full flow can be realized, and the sensitivity of the wear particle size detection can be guaranteed. See the following desc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com