Lens actuating device

A technology of lens actuation and moving parts, which is applied in installation, optics, instruments, etc., and can solve problems such as coils and magnetic bodies occupying a large space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

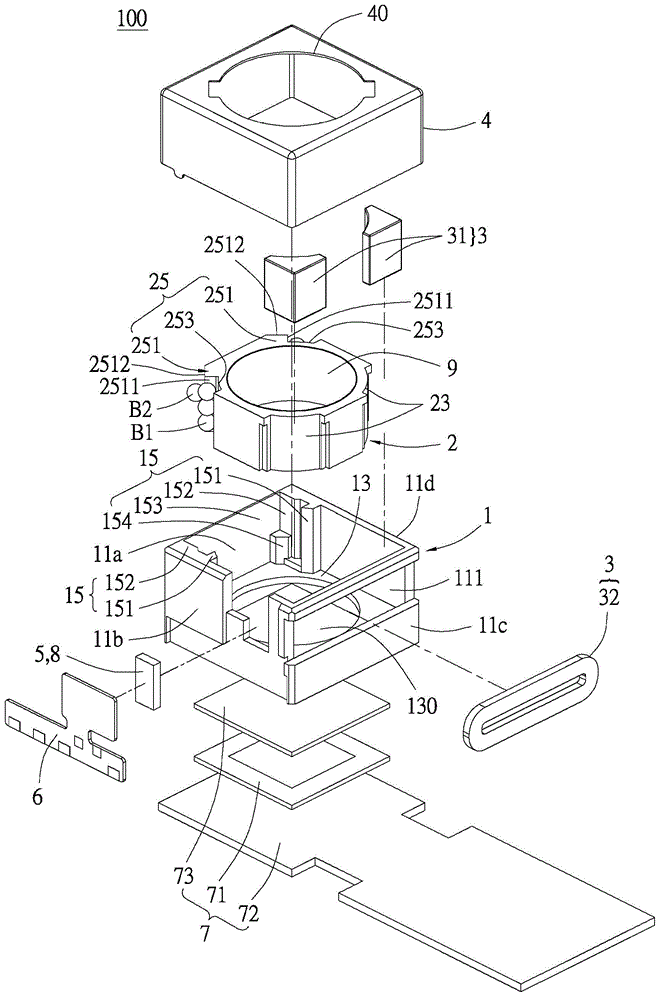

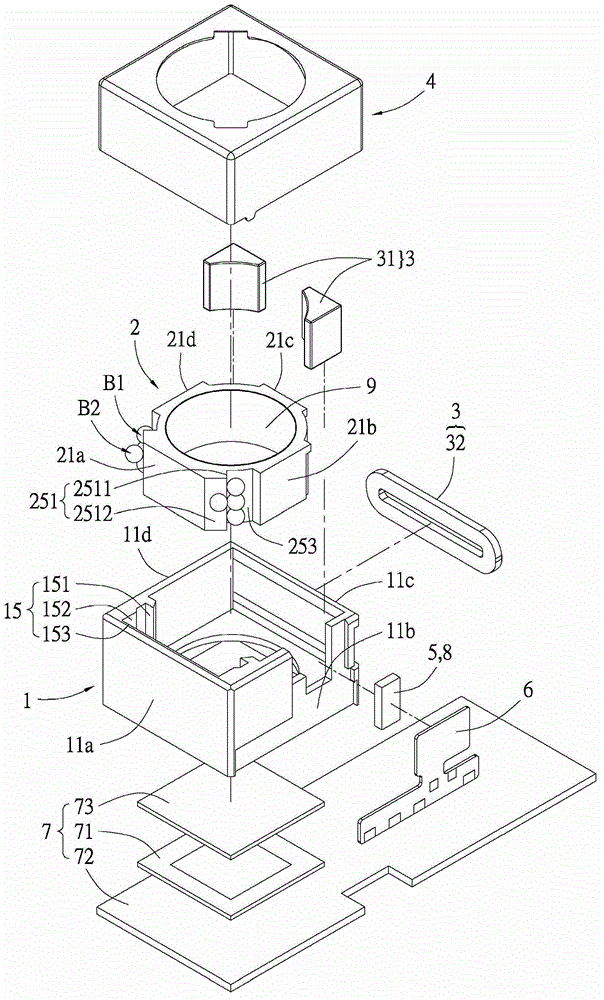

[0056] Please refer to figure 1 and figure 2 , is an exploded perspective view of the lens actuator device of the present invention. The present invention provides a lens actuating device 100, which includes a fixed part 1, a moving part 2, a driving unit 3 for providing driving force of the moving part 2, and a driving unit 3 for guiding and restricting the moving part 2 along the optical axis. A mobile supporting unit that moves in a direction, an outer cover 4 , a position sensing element 5 and a lateral traction element 6 . The above-mentioned moving part 2 is movably disposed in the fixing part 1 along the optical axis direction, and the moving part 2 is installed with a lens module 9 . The driving unit 3 is disposed between the fixing part 1 and the moving part 2 . The above optical axis direction refers to the axial center direction of the lens module 9 .

[0057] In this embodiment, in order to make the moving part 2 and its lens module 9 move accurately along the...

no. 2 example

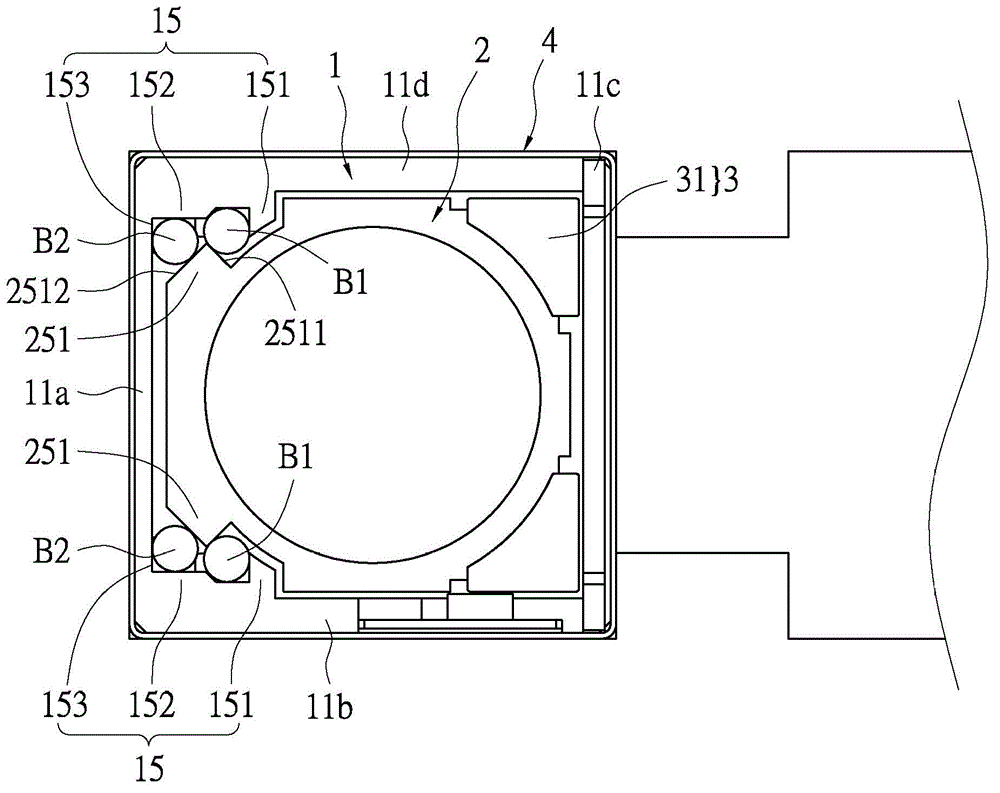

[0081] In the above embodiment, there are two rows of balls B1 and B2 at the two corners to hold the second guide structure 25 to provide forces in different directions to guide the moving part 2 to be correctly displaced on the optical axis. Therefore, there are four rows of spheres in order to achieve a better balance. However, as a supplementary note, in the present invention, the above-mentioned first and second guiding structures may be provided only at one corner, and only one column may be provided at the other corner, so as to achieve auxiliary balance.

[0082] Based on the above, the second embodiment of the present invention only uses three rows of spheres to achieve the above functions. see Figure 6 In this embodiment, a receiving groove 255 is arranged on the moving part 2, roughly corresponding to the middle of the first side wall 11a, and the receiving groove 225 accommodates another row of spheres B2' (in this embodiment, circular spheres). The above-mention...

no. 3 example

[0084] The difference from the second embodiment is that the rolling element R2 of this embodiment is cylindrical, and for matching the rolling element R2, this embodiment has a wider receiving groove 255'.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com