Descent control hinge for closestool

A toilet and slow-down technology, which is applied to the field of slow-down hinges for toilets, can solve the problems of unsatisfactory positioning structure design, cumbersome installation and disassembly steps, unsafe connection structure, and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

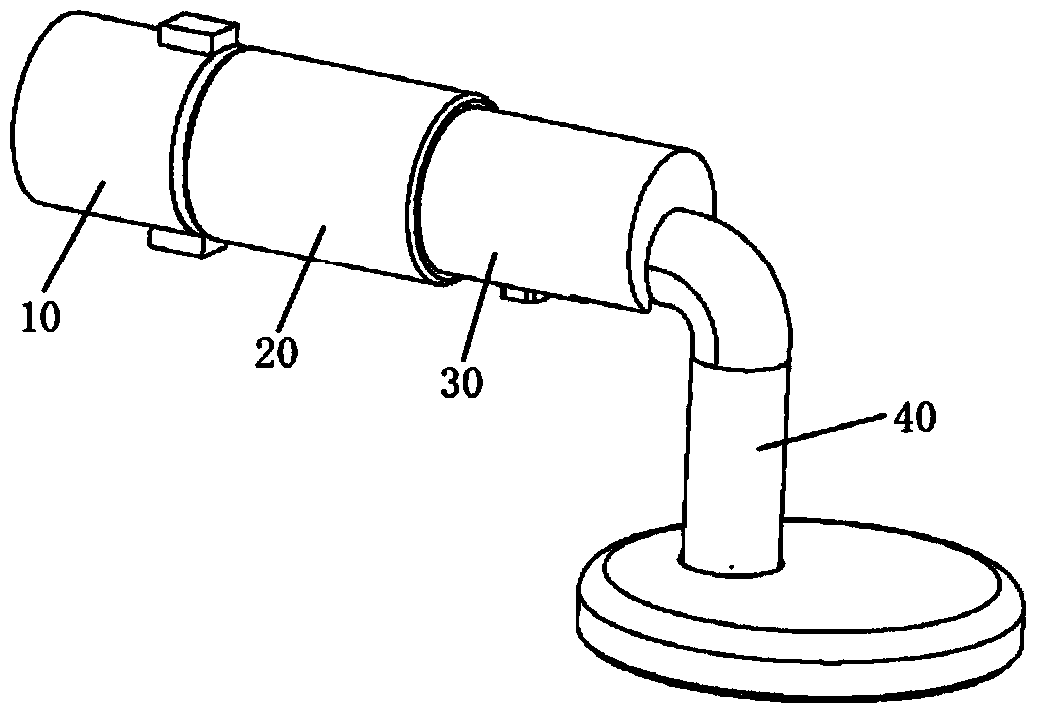

[0045] Such as Figure 1 to 14 As shown, a slow-down hinge for a toilet includes a rotating connecting body 10, a descending device 20, a connecting frame 30, and a plug post 40. The rotating connecting body 10, the descending device 20 and the connecting frame 30 are sequentially connected Form a slow-down hinge unit.

[0046] The bottom of the plug post 40 is fixedly connected to the toilet, and the plug post 40 is movably inserted in the slow-down hinge unit.

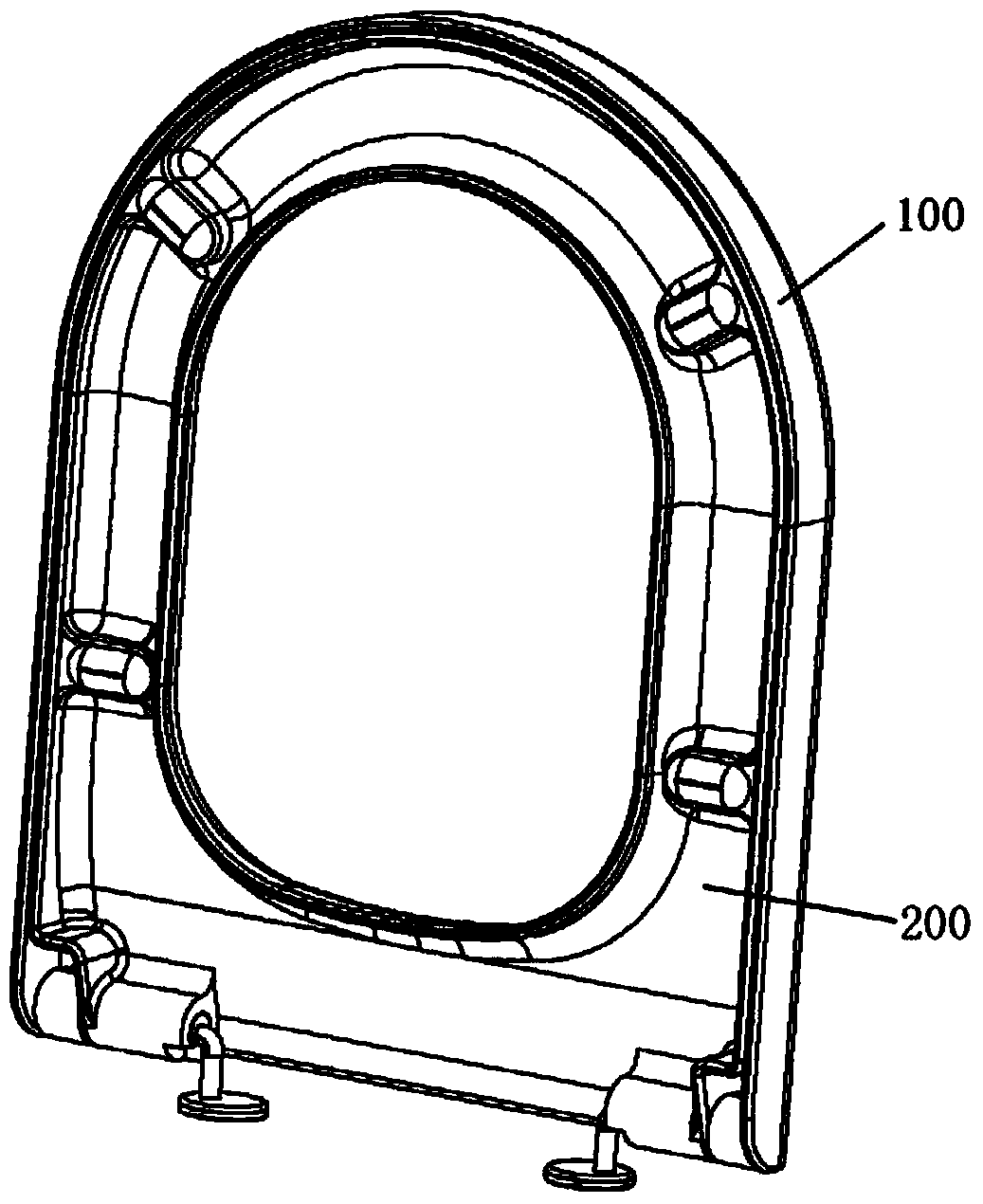

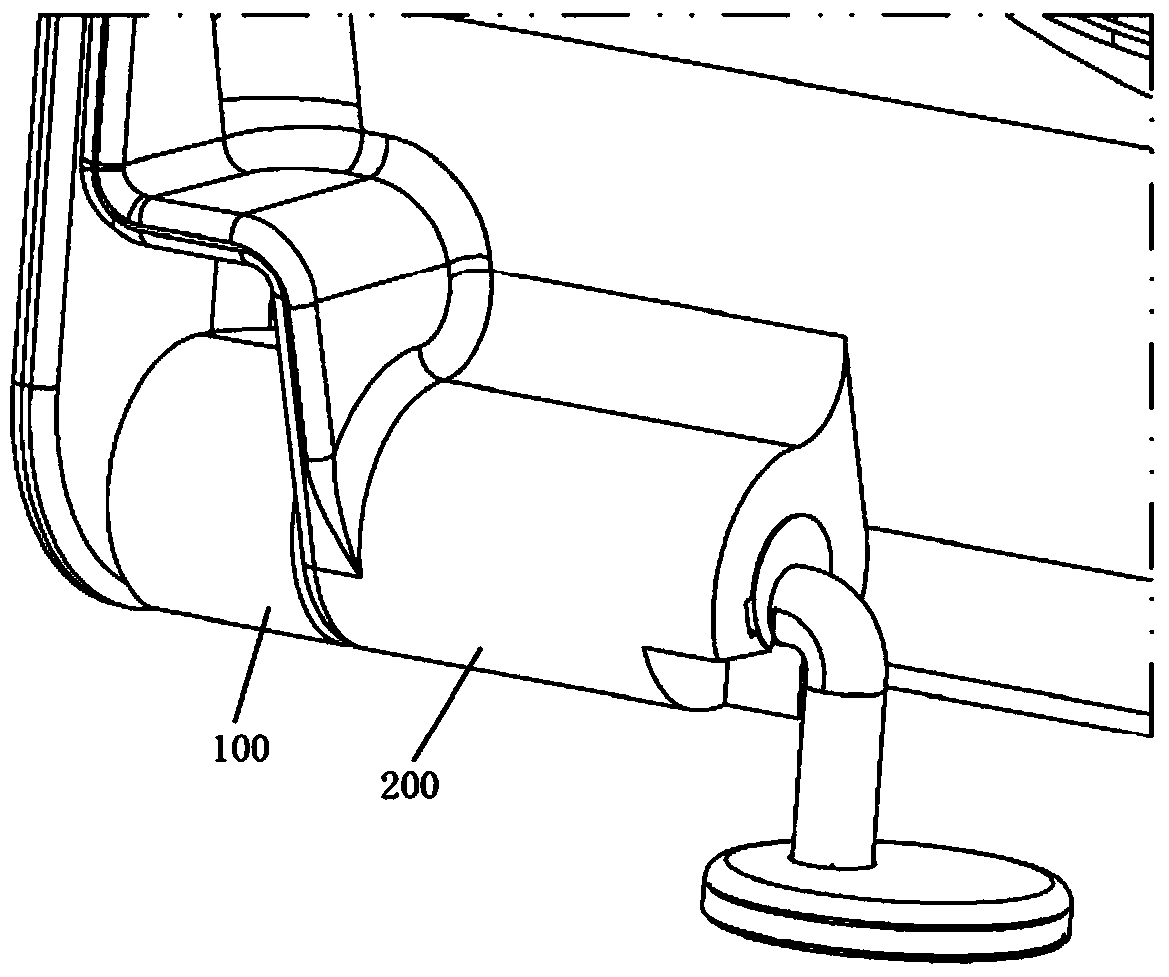

[0047] A toilet cover assembly hole 110 is opened at the bottom end of the toilet cover 100, and a seat assembly hole 210 is opened at the bottom end of the toilet seat 200.

[0048] The toilet lid assembly hole 110 communicates with the seat assembly hole 210, and communicates with the seat assembly hole 210 through the toilet lid assembly hole 110 to form a hinge assembly hole, and the slow-down hinge unit is disposed in the hinge assembly hole .

[0049] The front end of the rotating connecting body 10 is arranged in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com