Single-span simply supported beam bridge structure applicable to coal mining subsidence area

A technology for mining subsidence areas and simply supported girder bridges, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as limited and irrespective of surface deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further explained below in conjunction with the accompanying drawings.

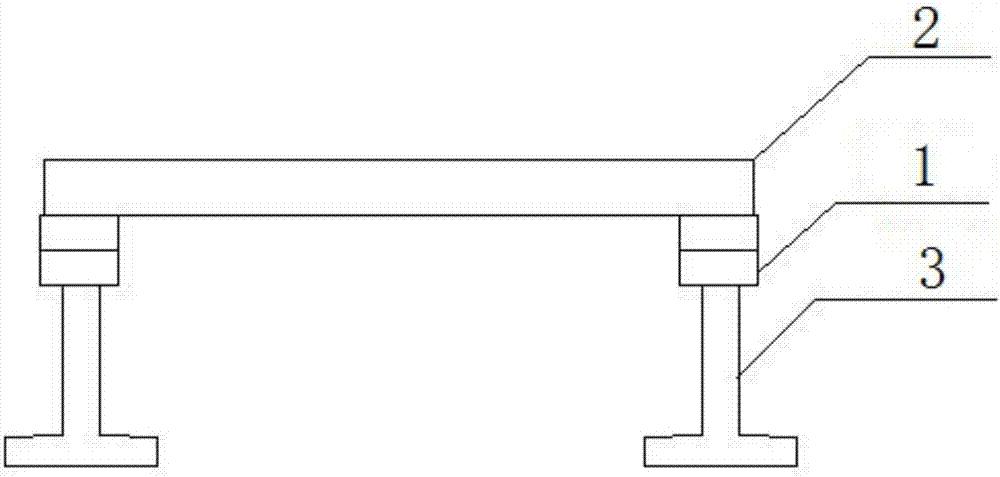

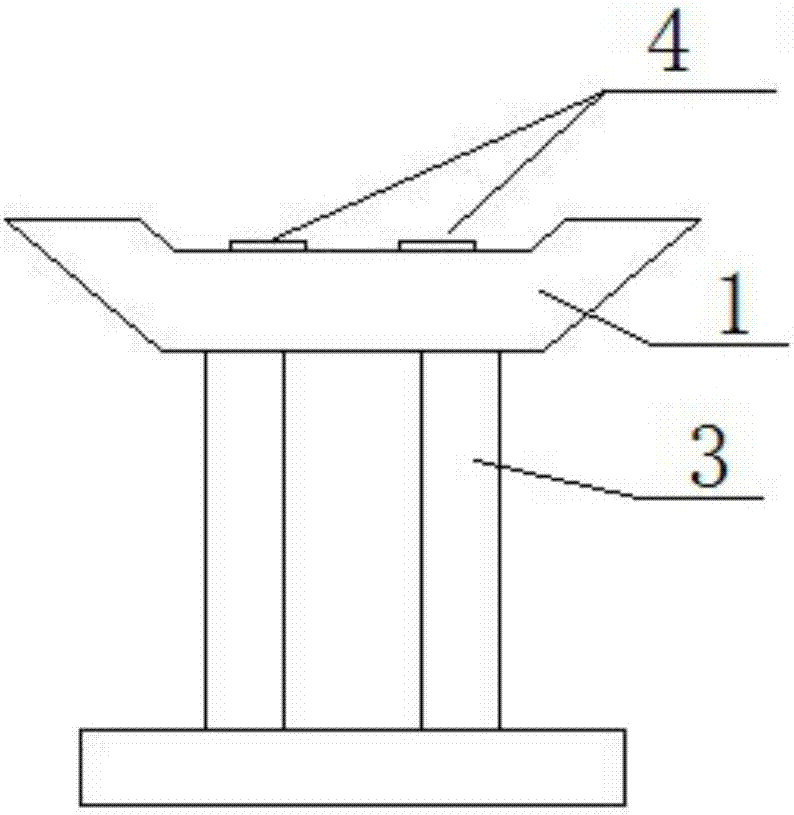

[0018] Such as figure 1 As shown, a single-span simply supported girder bridge structure suitable for coal mining subsidence area consists of abutment 1, bridge deck 2, foundation 3, and support 4. The bridge deck is a reinforced concrete hollow slab girder, and the span between abutments is not more than 30m. The top surface of the abutment is a broken line structure, which is composed of a horizontal plane in the middle and inclined surfaces on both sides. The included angle between the inclined plane and the horizontal plane is 15-30 degrees. figure 2 As shown, a concave shape is formed. The foundation adopts the expanded foundation, which is set above the ground surface, and no foundation backfilling is carried out. The number of bearings is 3, of which 2 are placed on the horizontal plane of the abutment on one side, and the other is placed on the horizontal p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com