Soldering iron

A soldering iron, cutting-edge technology, applied in the direction of soldering irons, soldering stations, auxiliary devices, etc., can solve the problems of reduced efficiency of current flow, secondary battery safety problems, etc., and achieve the effect of reducing soldering operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

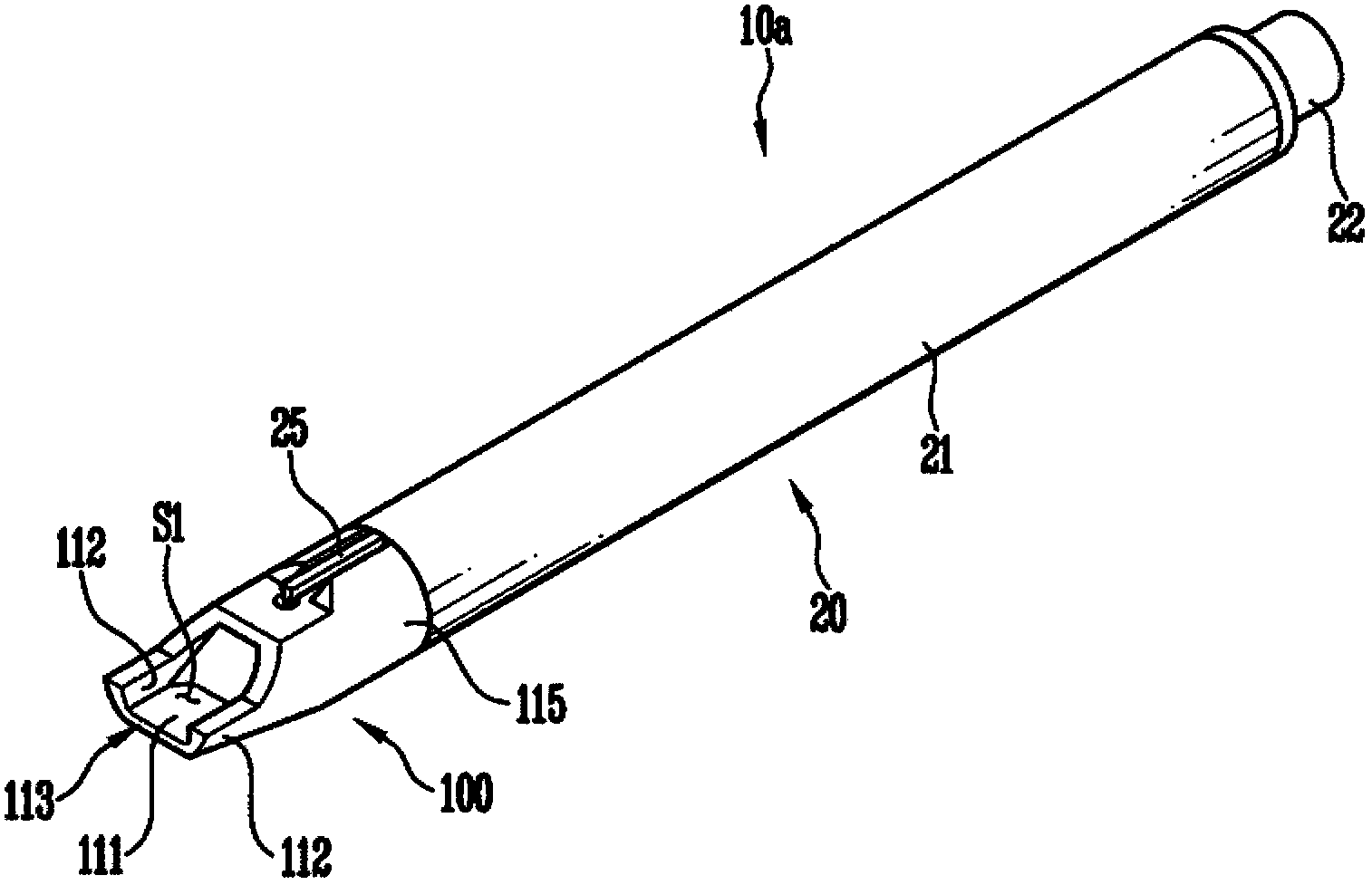

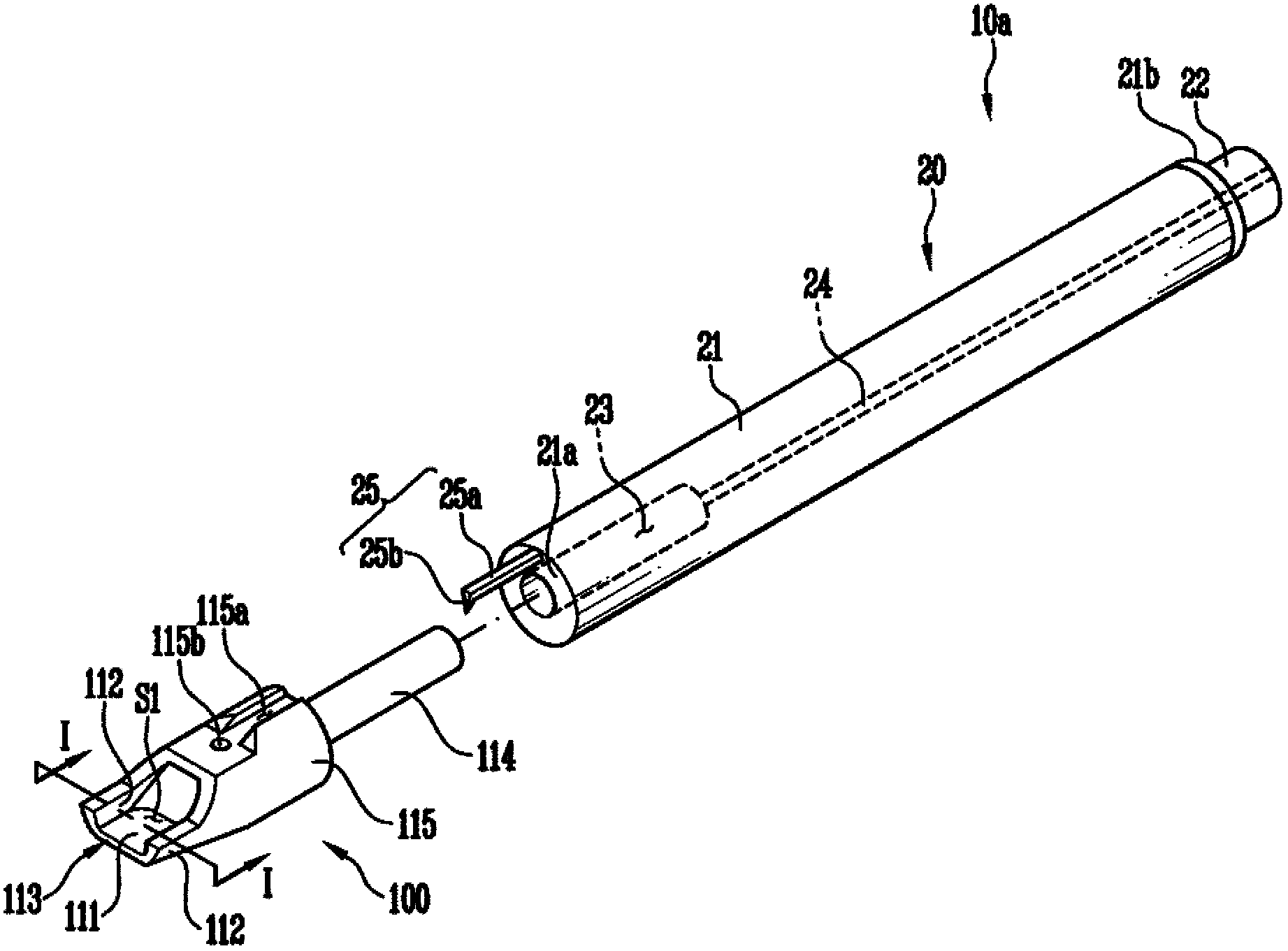

[0036] figure 1 is a perspective view of a soldering iron according to an embodiment of the present invention. figure 2 for figure 1 exploded perspective view of a soldering iron.

[0037] The soldering iron 10a according to this embodiment is used when components are soldered to the board. The soldering iron 10 a may include a tip portion 100 that melts lead and has a bent portion that contacts the lead, and a tip fixing portion 20 that has a heater that heats the tip portion 100 .

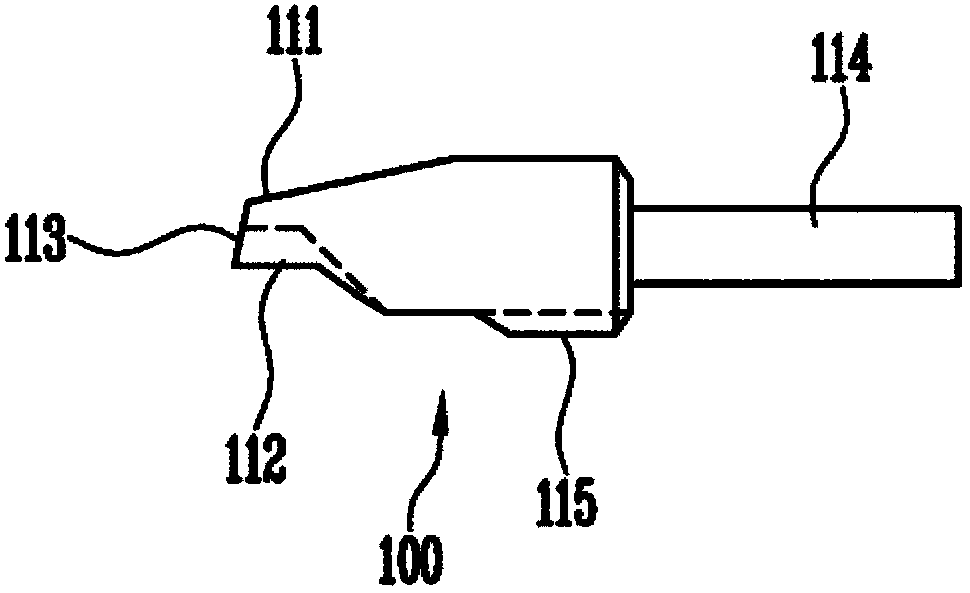

[0038] The tip portion 100 is a portion that melts lead by direct contact with lead. The tip part 100 may include a base 111 in direct contact with the lead, side parts 112 bent at one end and the other end of the base 111, respectively, a support part 115 connected to the upper part of the side part 112 and the base 111, and a tip from the support part 115 toward the tip. The extension 114 protrudes from the fixing part 20 . The base part 111 , the support part 115 and the extension part 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com