Patents

Literature

30results about How to "Reduce welding operations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

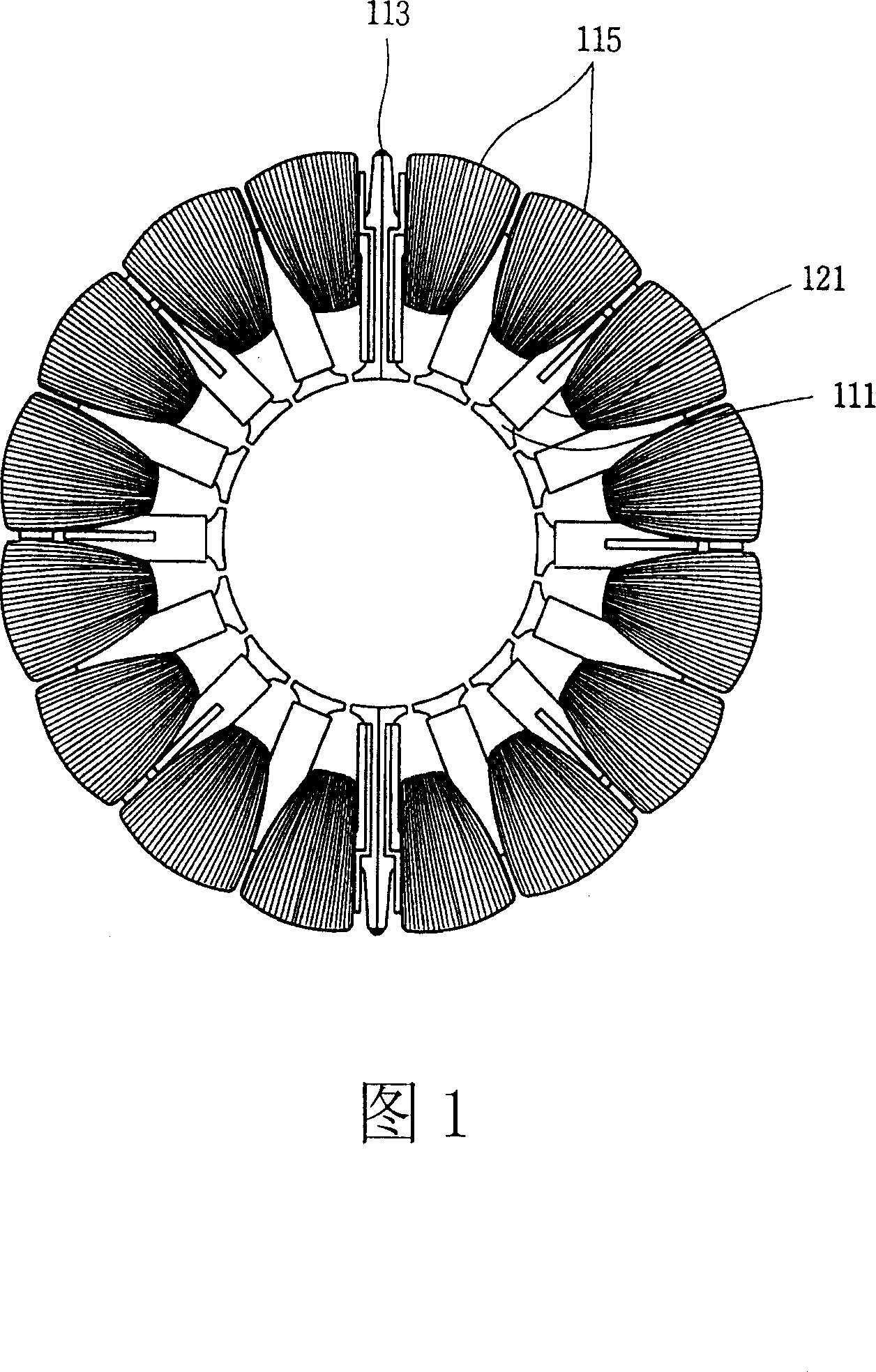

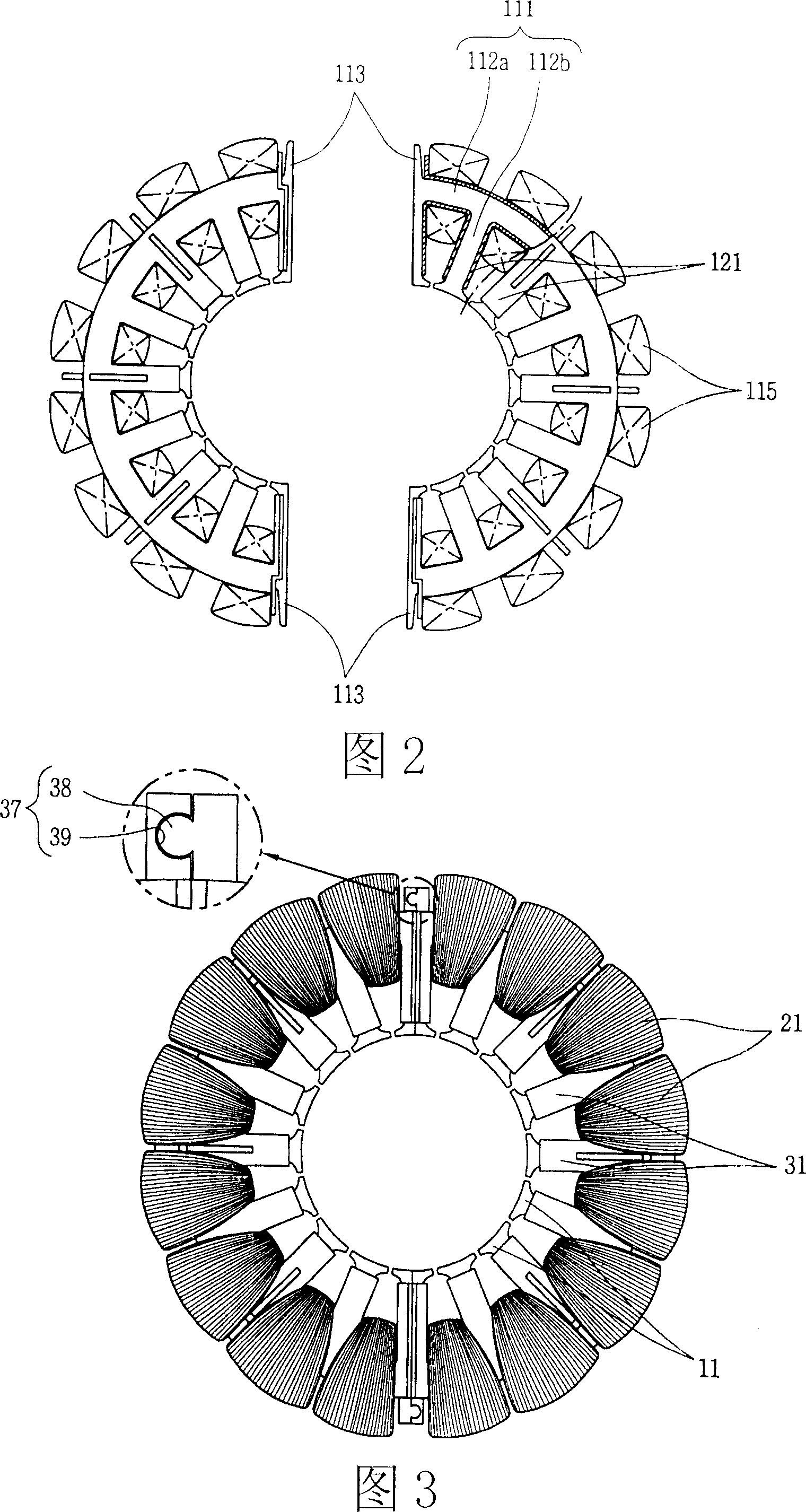

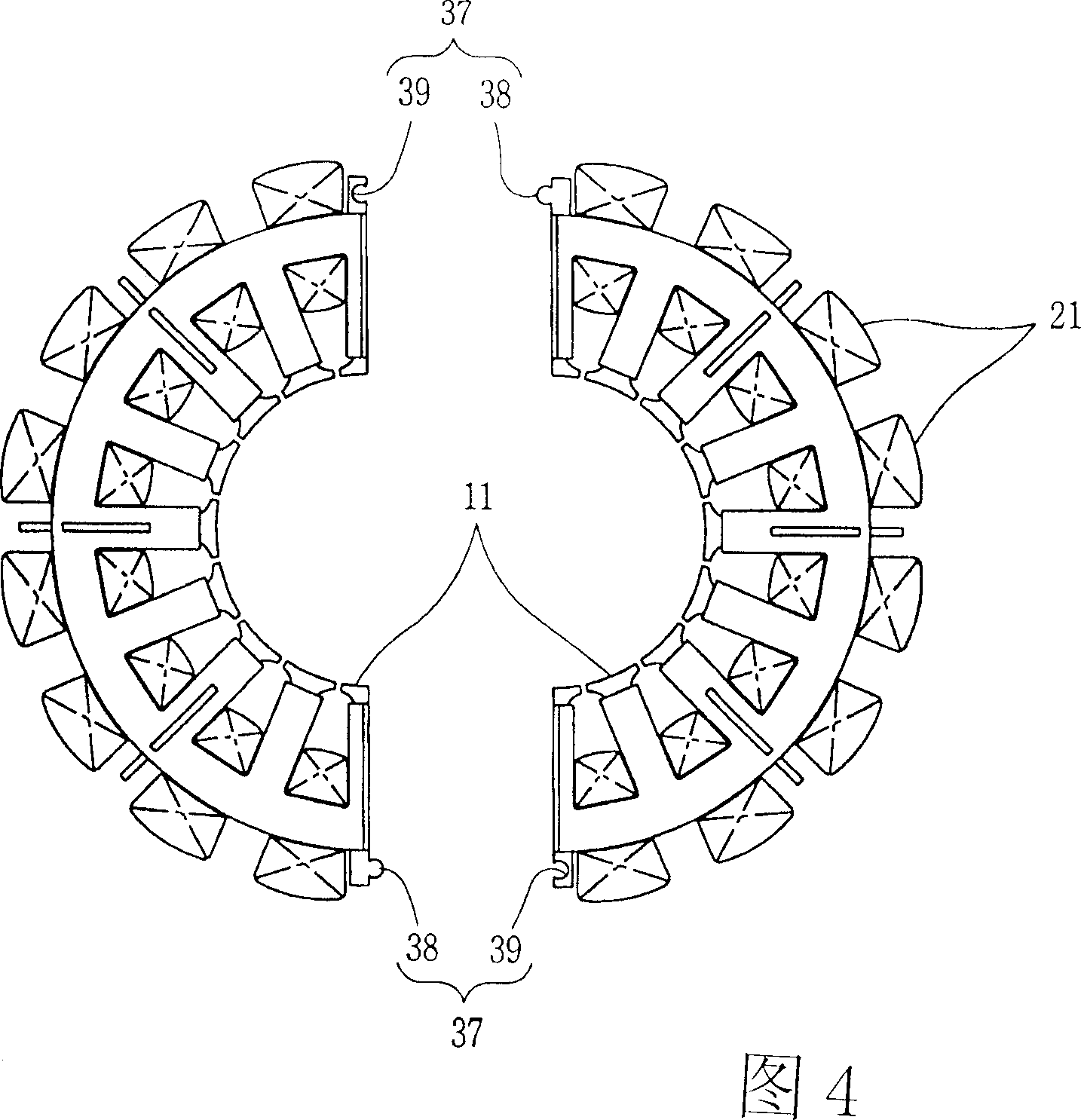

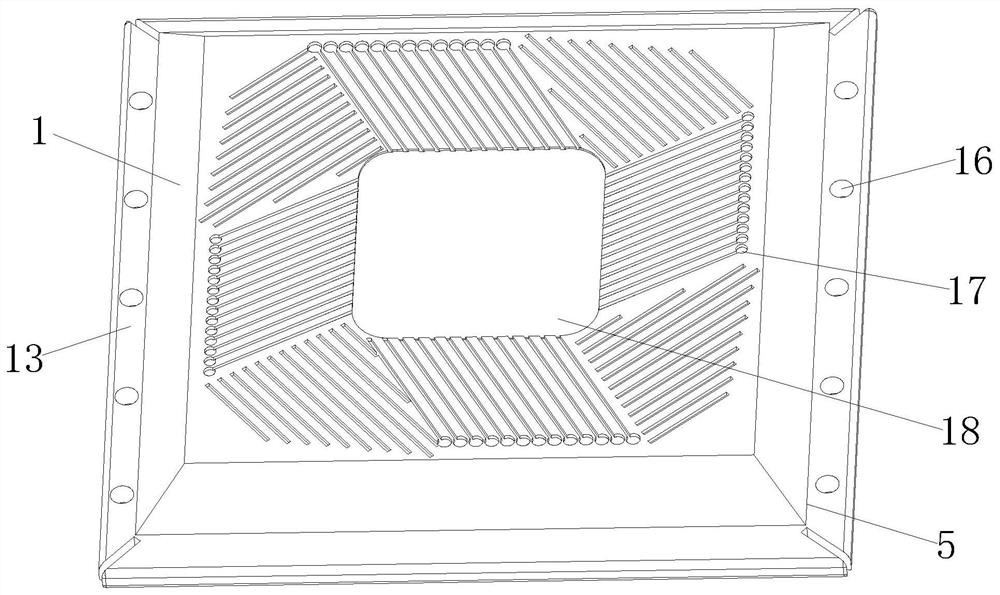

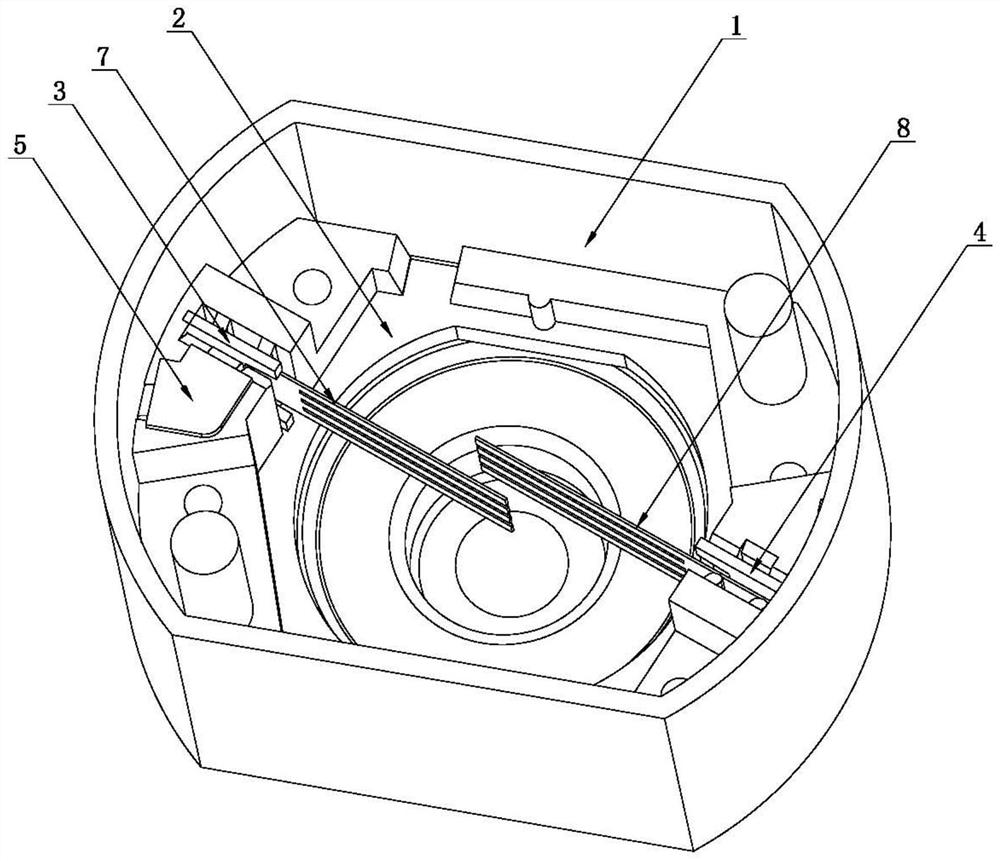

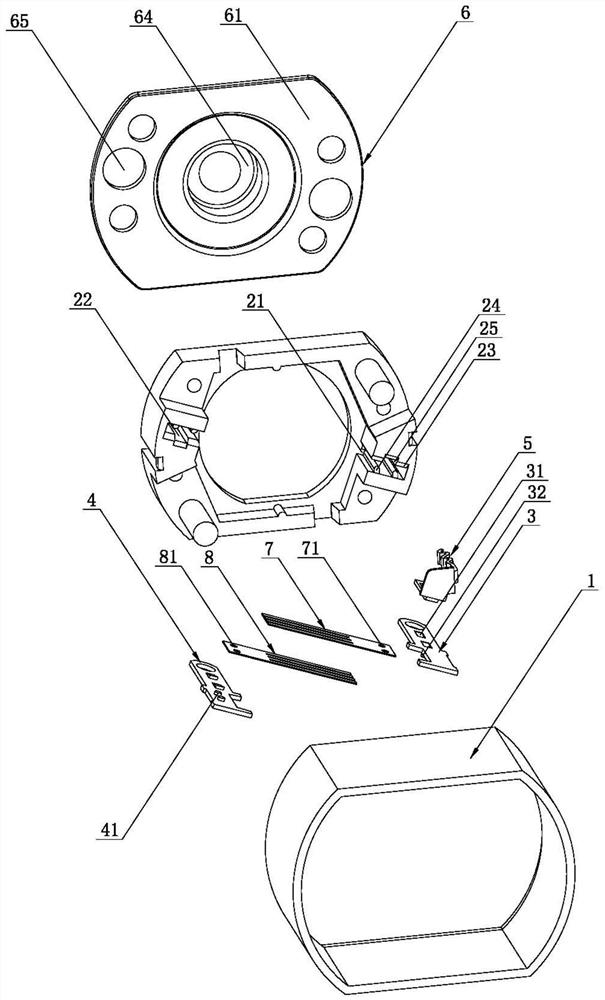

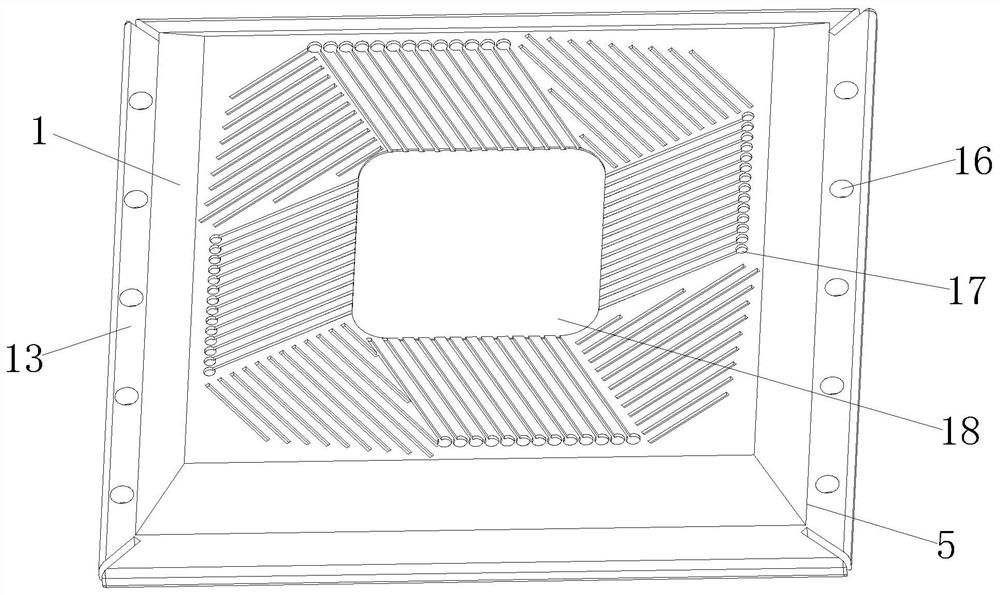

Stator for annular generator

InactiveCN1925260AReduce welding operationsPrevent thermal deformationWindings insulation shape/form/constructionMagnetic circuit stationary partsStator coilElectrical and Electronics engineering

This ring motor stator, which comprises the following parts: magnetic yoke part with arc shape and its protruding part along radium direction and several gear parts to form plug tank between with certain distance to form several cutting stator iron chip; stator coil outside magnetic yoke; several insulation iron chip of the magnetic yoke parts and gear parts and stator iron chip; protruding part set relative to the binding place near to the insulation; one integration part to integrate insulation parts and stator iron chips.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

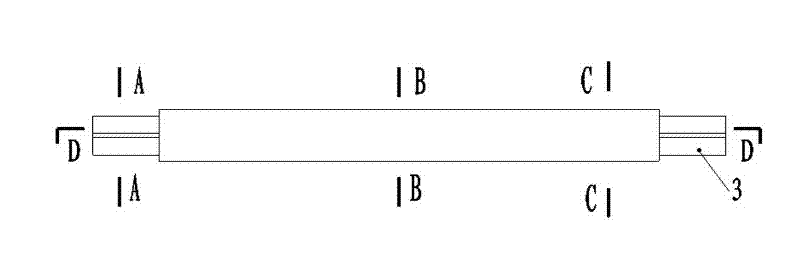

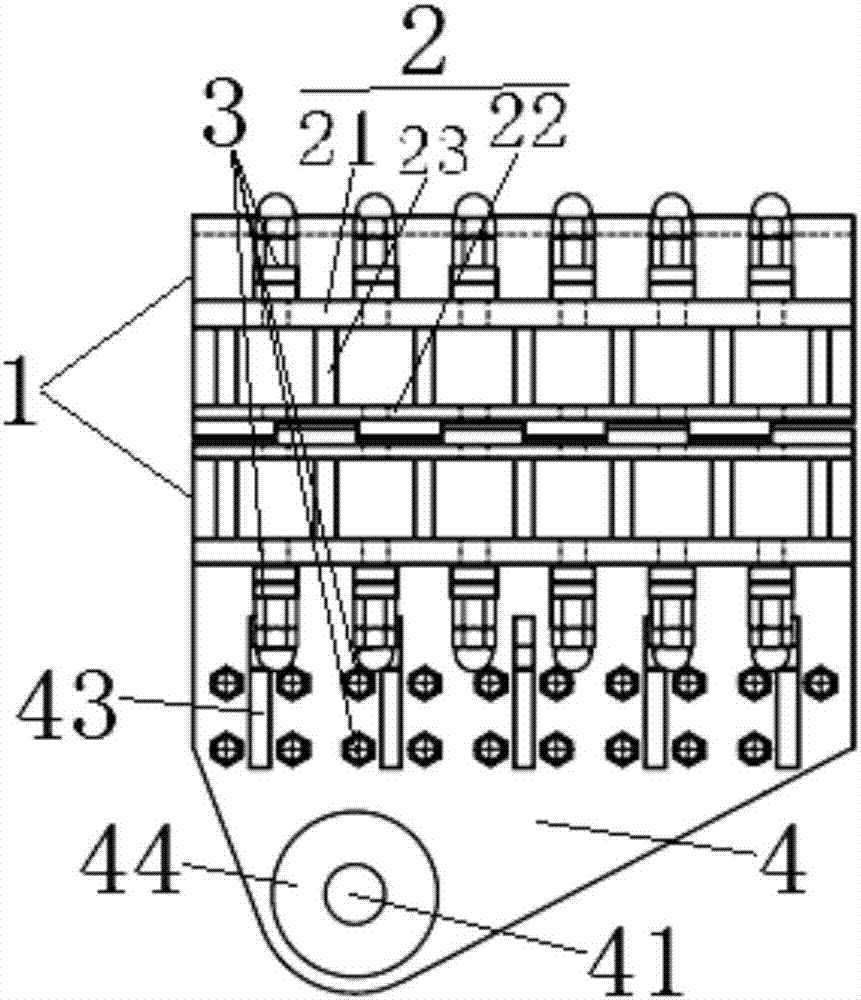

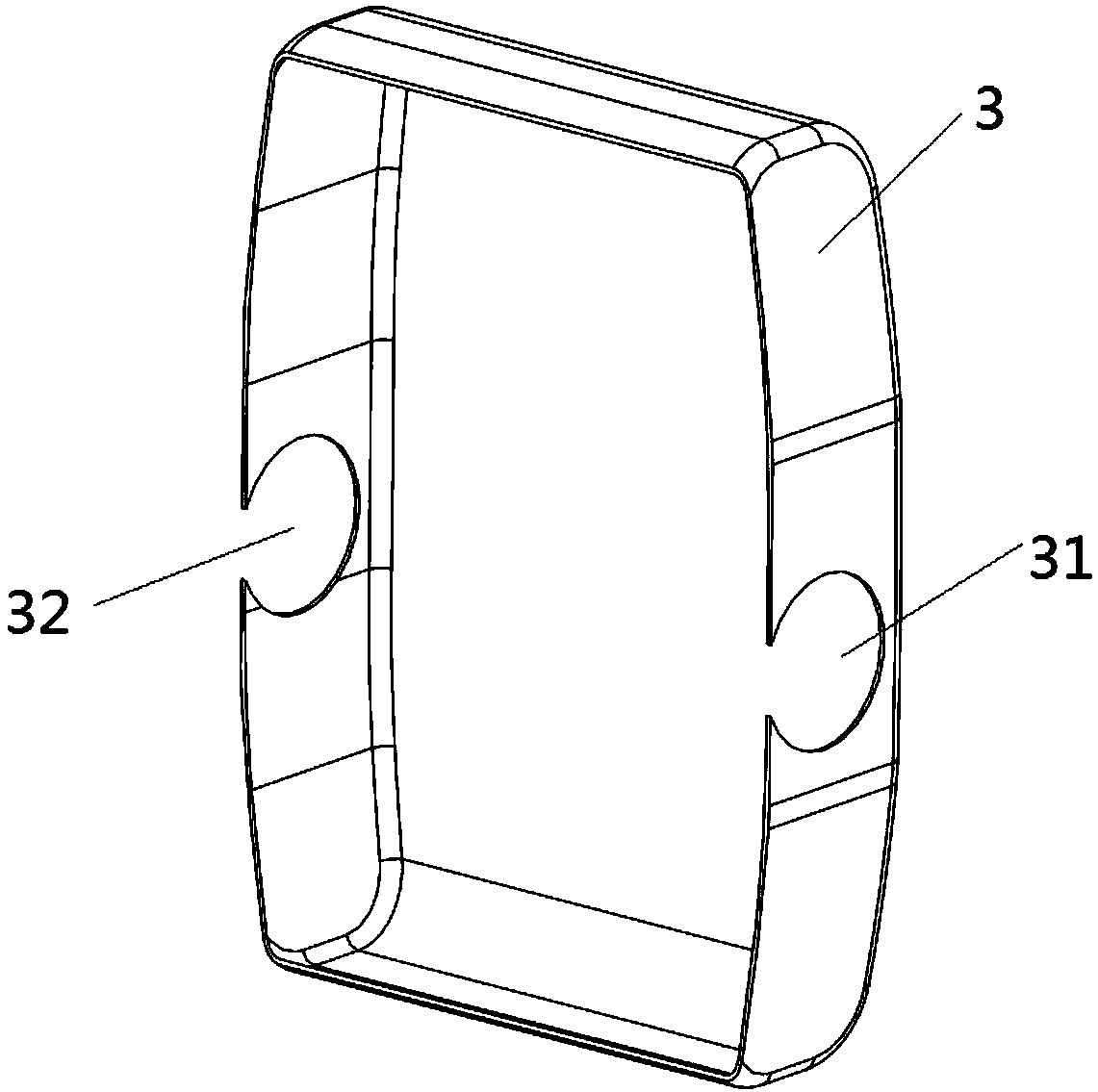

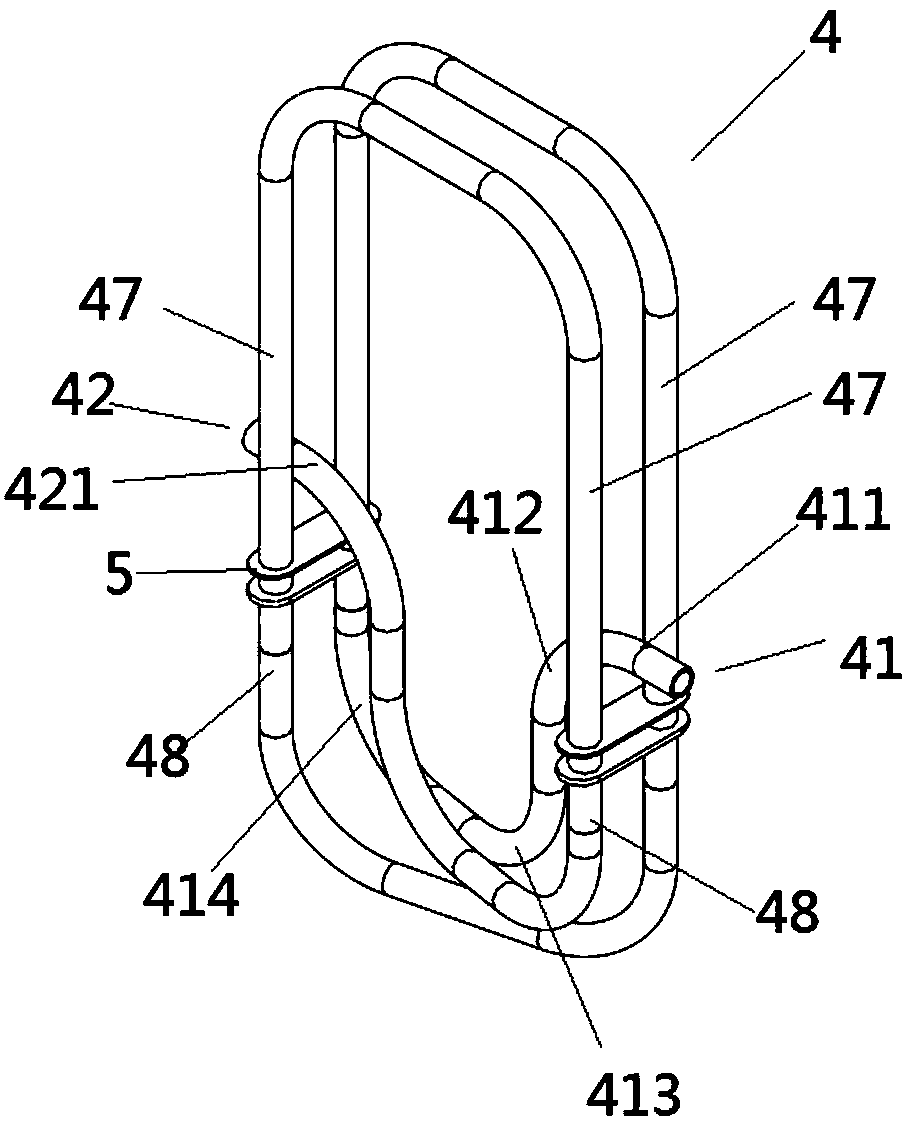

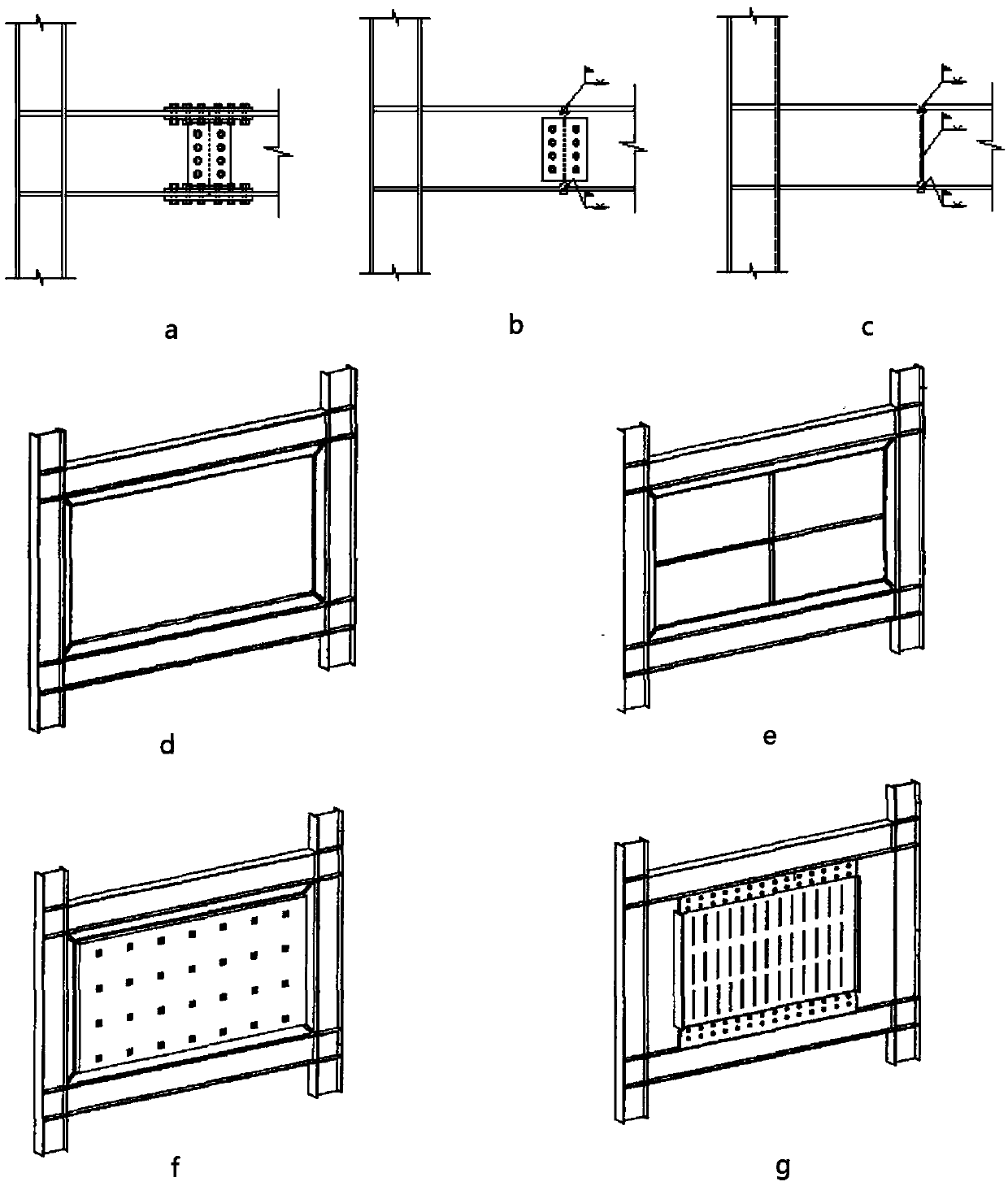

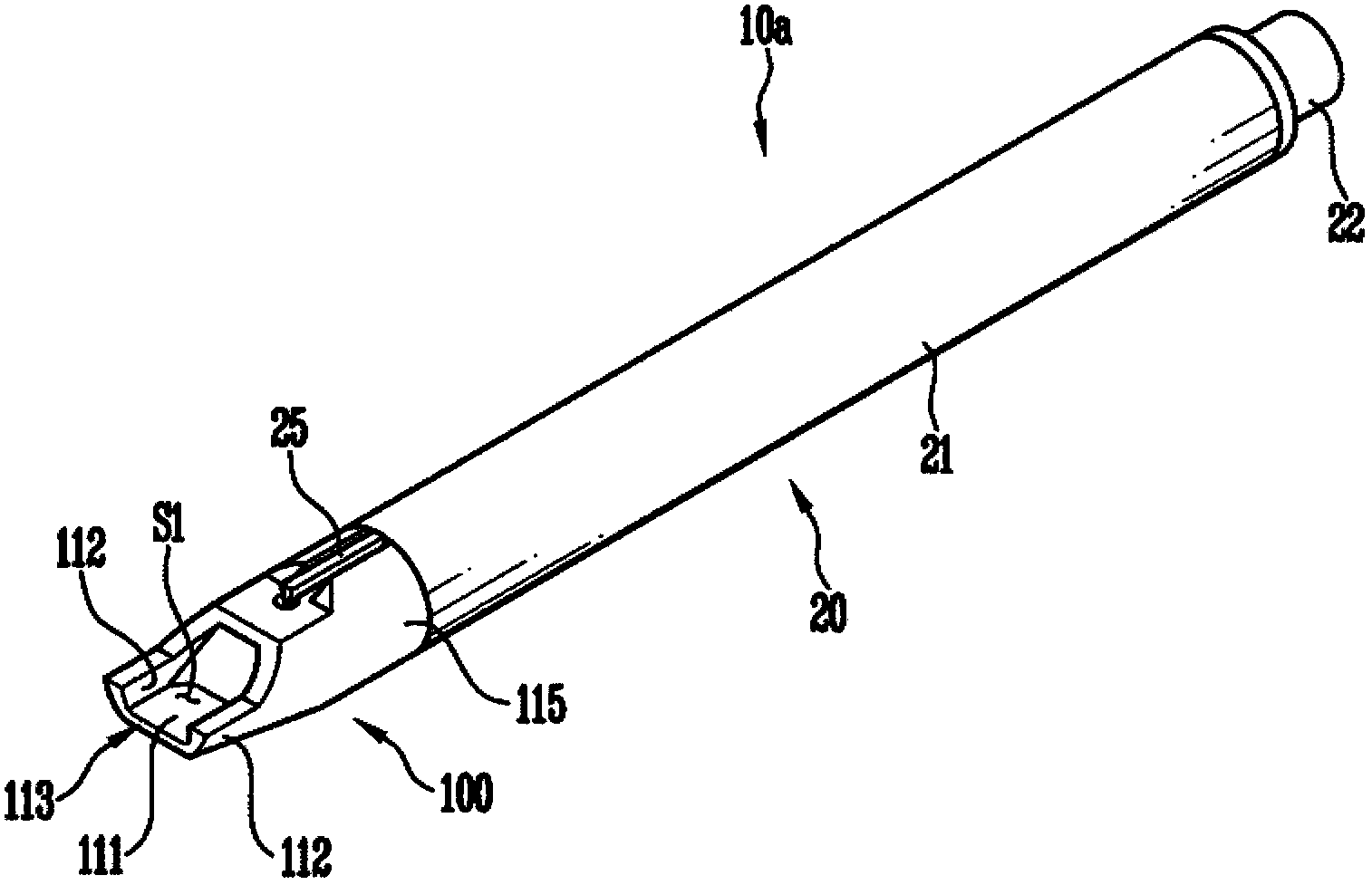

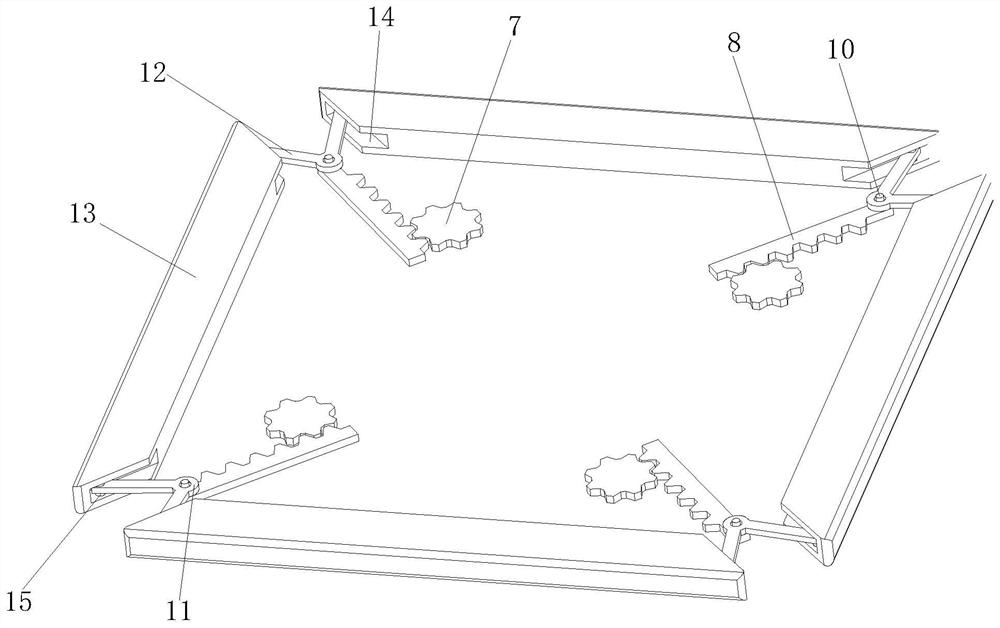

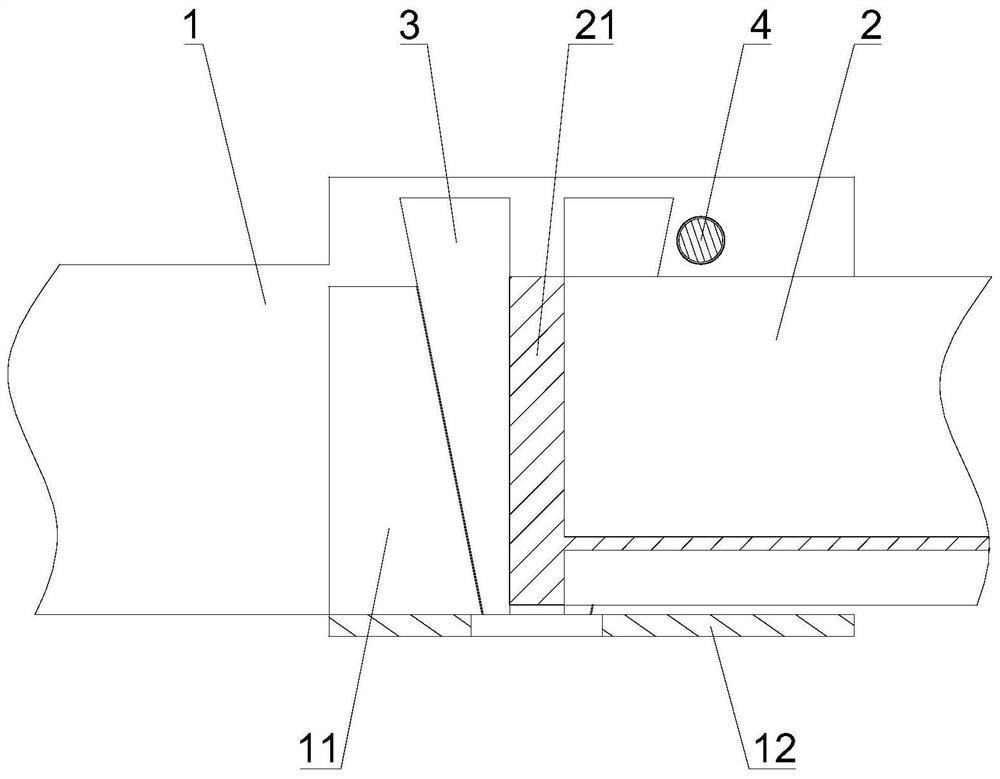

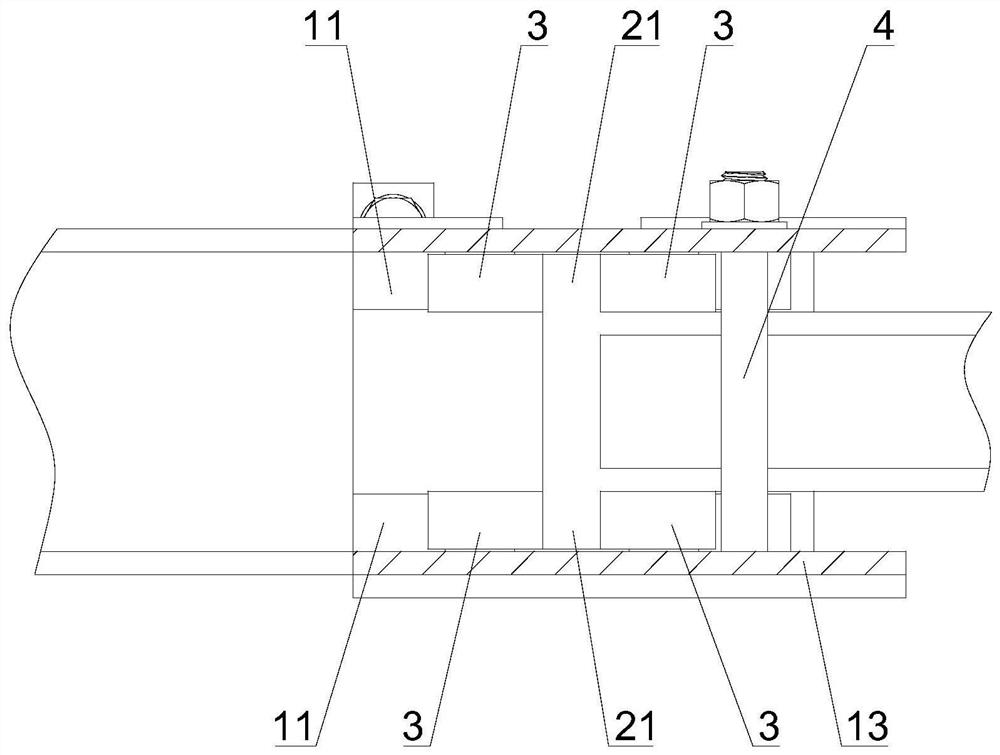

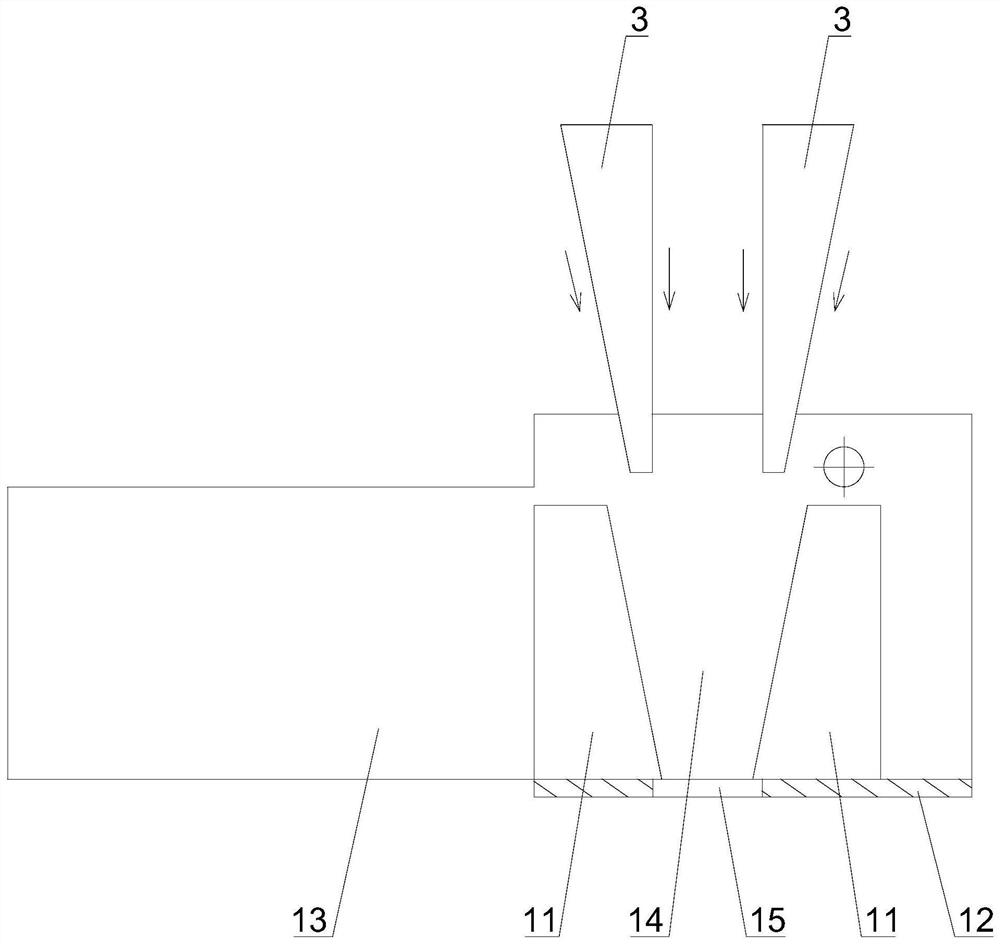

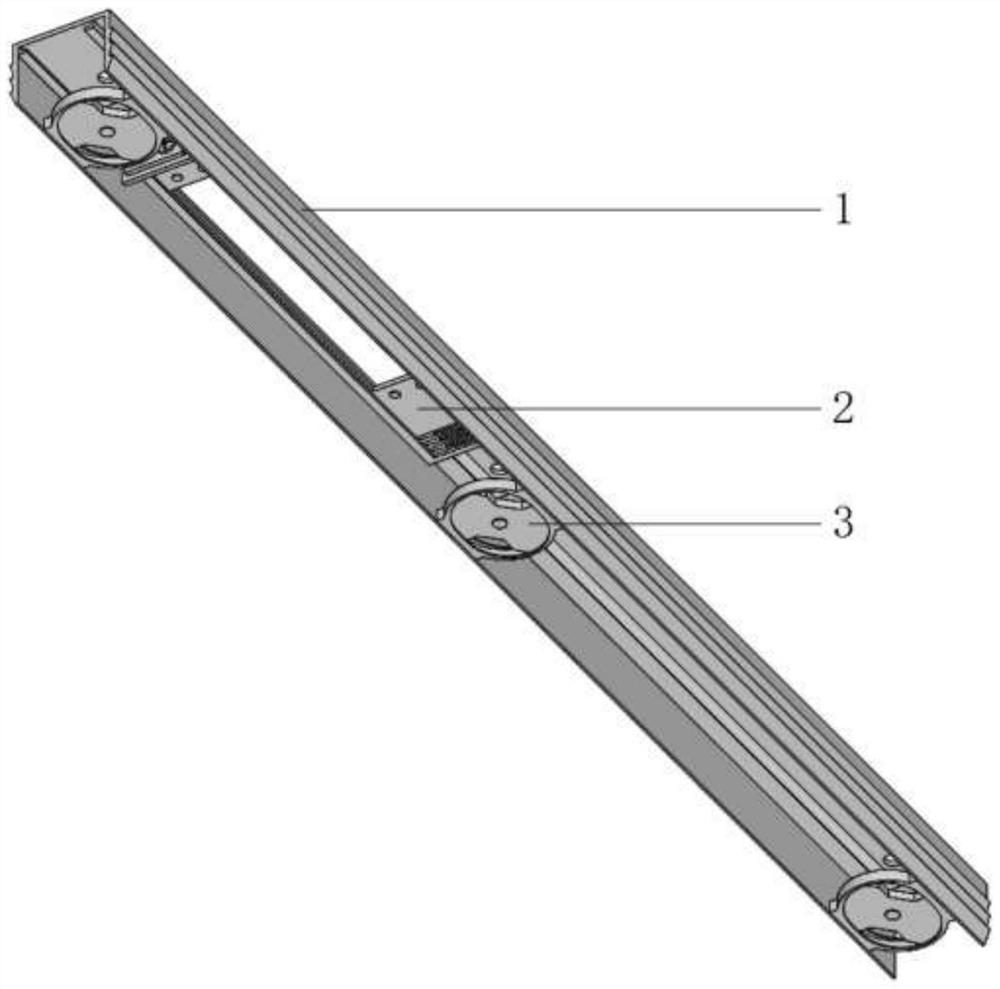

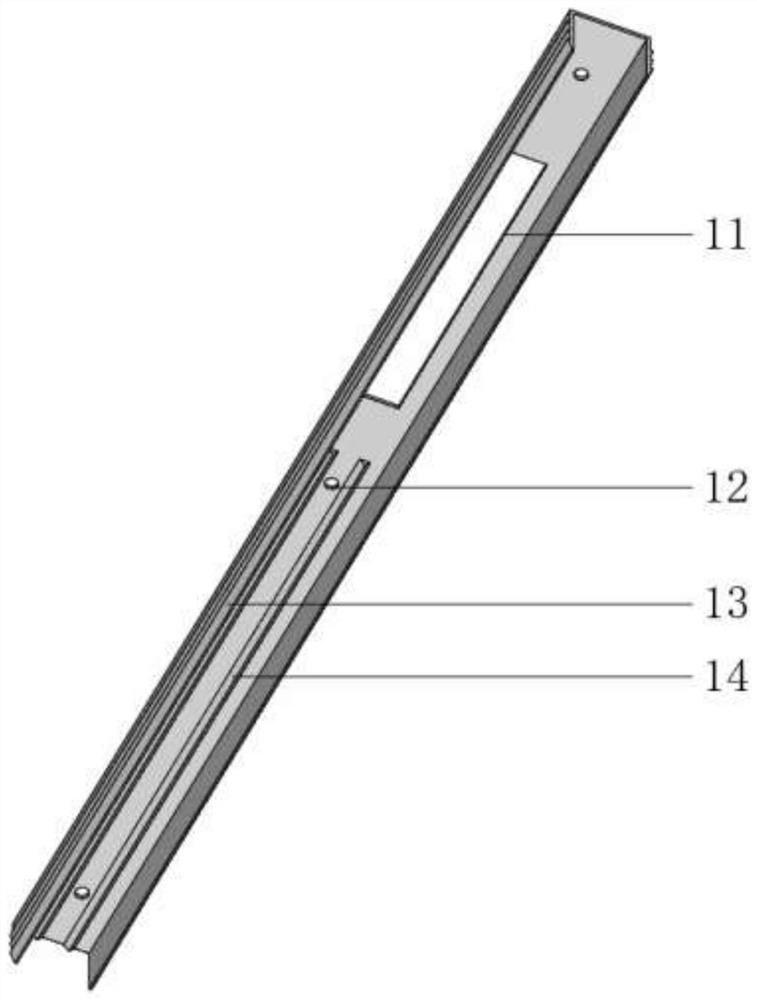

Rod type core bar bending restrain steel support

InactiveCN101974950BImprove local stabilityImprove buckling resistanceShock proofingBuckling-restrained braceSteel frame

The invention relates to a rod type core bar bending restrain steel support which solves the problems of large difference of rigidity and stability of all directions of an energy dissipation section of the traditional bending restrain support, difficult support installation and complex restrain construction. A core main stress part comprises an energy dissipation section, conversion sections and an installation section, wherein the energy dissipation section is a solid steel bar or hollow steel pipe; an outer restrain steel part comprises a local restrain steel member and an integral restrainsteel member, the local restrain steel member comprises a core bar steel sleeve, the integral restrain steel member comprises a delay steel frame fixed outside the core bar steel sleeve and an auxiliary steel cylinder; one section of the two conversion section is in friction contact with the steel cylinder of the conversion section and a gap is remained between the core bar steel sleeve and the delay steel frame. The section of the energy dissipation section of the support has uniform size in all directions, which eliminates the difference of the rigidity and the stability of different directions, thus the local stable bearing capacity and the integral bending-preventing capacity are high, and the working reliability under large axial direction strain and strong shock is high; and the rodtype core bar bending restrain steel support is convenient for installation, and is suitable for engineering earthquake fortification and reinforcement.

Owner:山西恒晋减震科技股份有限公司

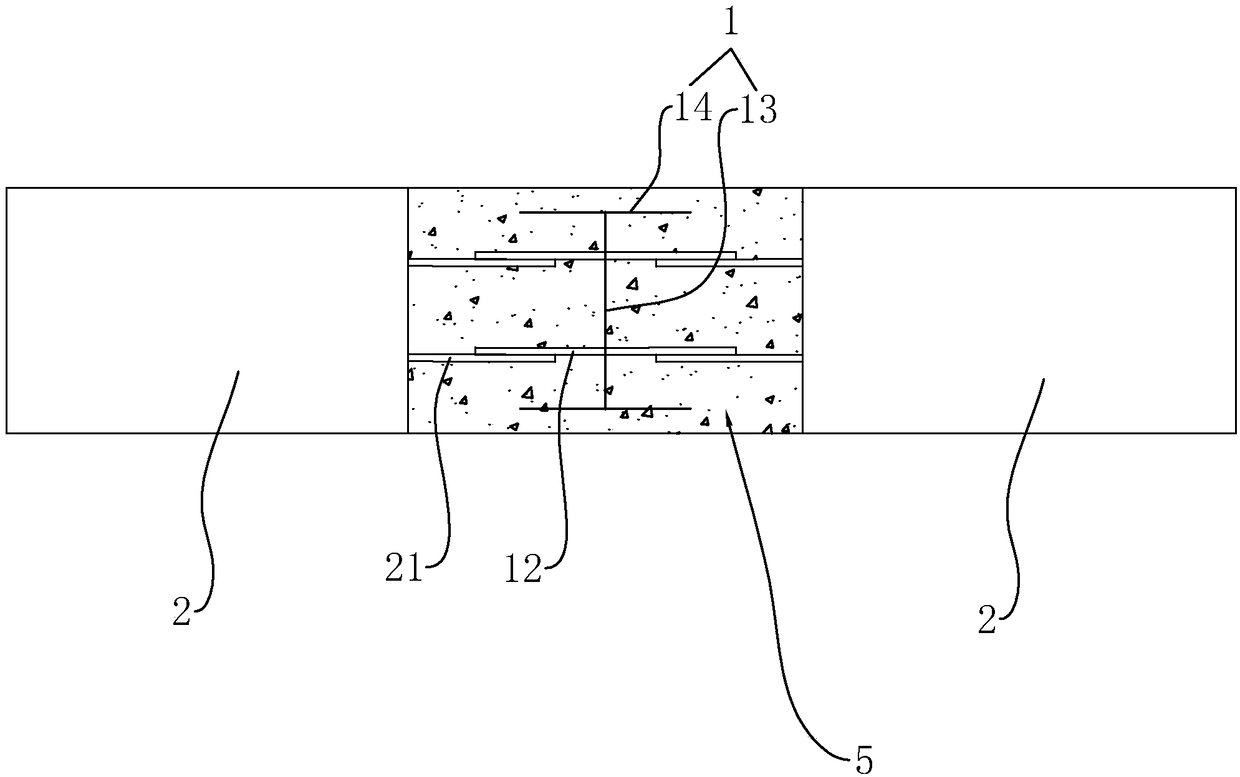

Connecting structure for prefabricated concrete wall panels and steel columns and construction method thereof

The invention discloses a connecting structure for prefabricated concrete wall panels and steel columns. The key point of the technical scheme is as follows: the connecting structure comprises sectionsteel columns and the prefabricated concrete wall panels, the section steel columns are vertically arranged, the prefabricated concrete wall panels are arranged in at least two directions of four side faces of each section steel column, and the prefabricated concrete wall panels and the section steel columns compose a straight, L-shaped, T-shaped or cross wall structure; post-cast strips are arranged between the section steel columns and the prefabricated concrete wall panels; connecting rebars which horizontally extend out are perpendicularly and fixedly connected to the four side faces of each section steel column, embedded rebars are arranged in the end surface, which is close to the section steel column, of each prefabricated concrete wall panel, part of each embedded rebar is locatedin a wall, and the other part extends into the post-cast strip; and after being fixedly connected, the connecting rebars and the embedded rebars are buried in concrete of the post-cast strips. The connecting structure ensures that the connection between the prefabricated concrete wall panels and the steel columns has good integrity and is steadier.

Owner:李藏柱

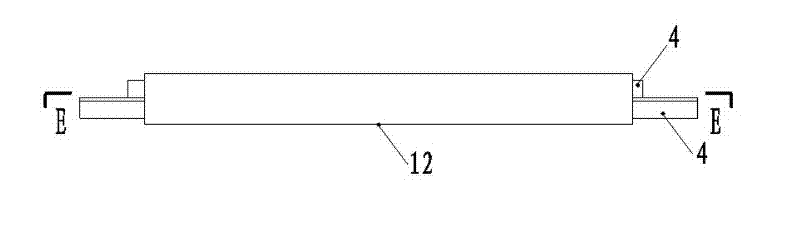

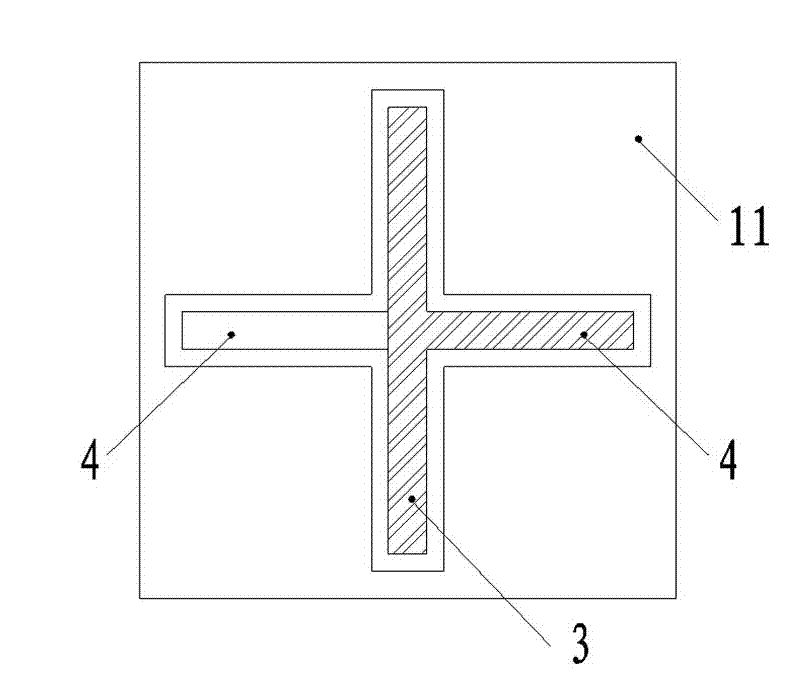

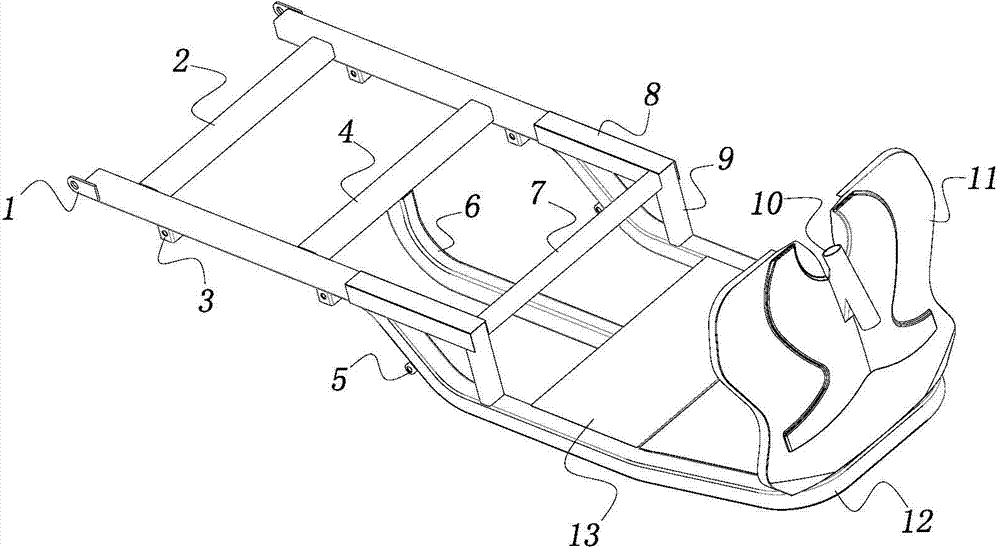

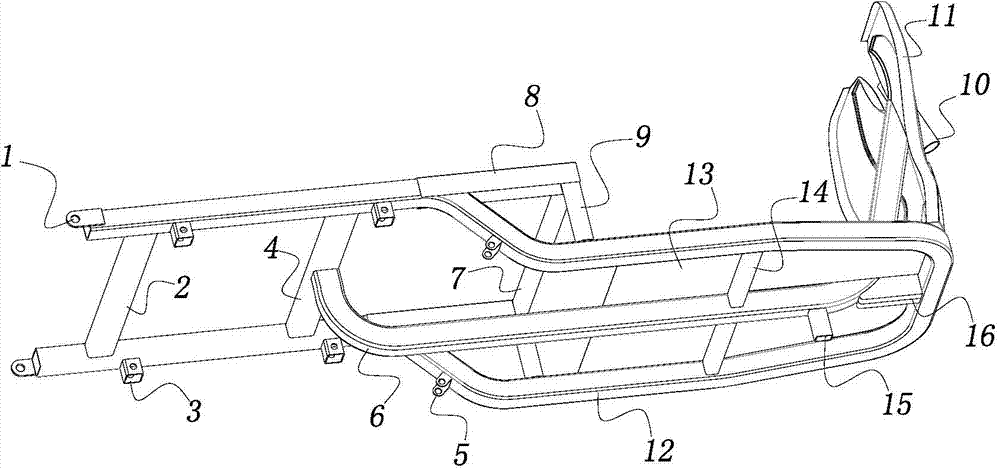

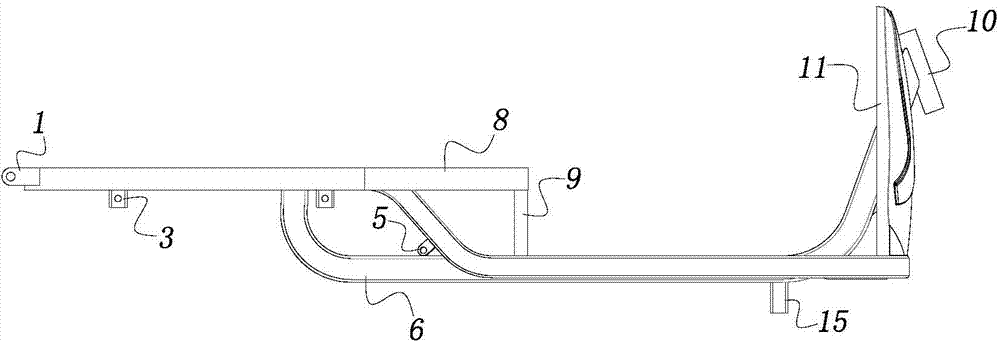

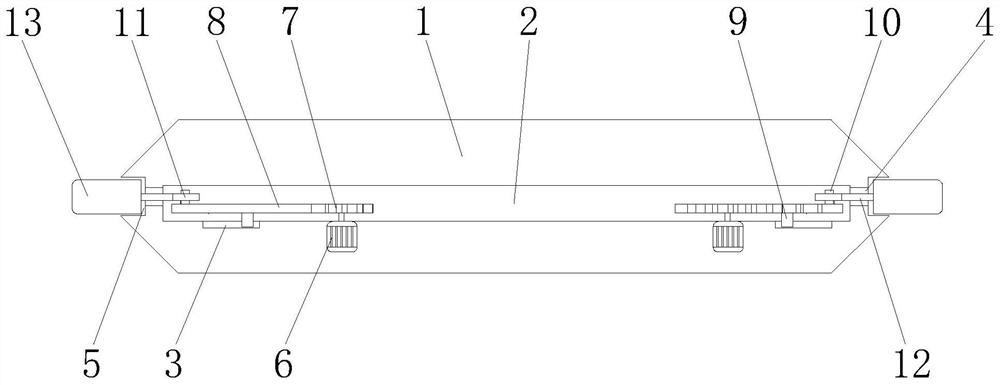

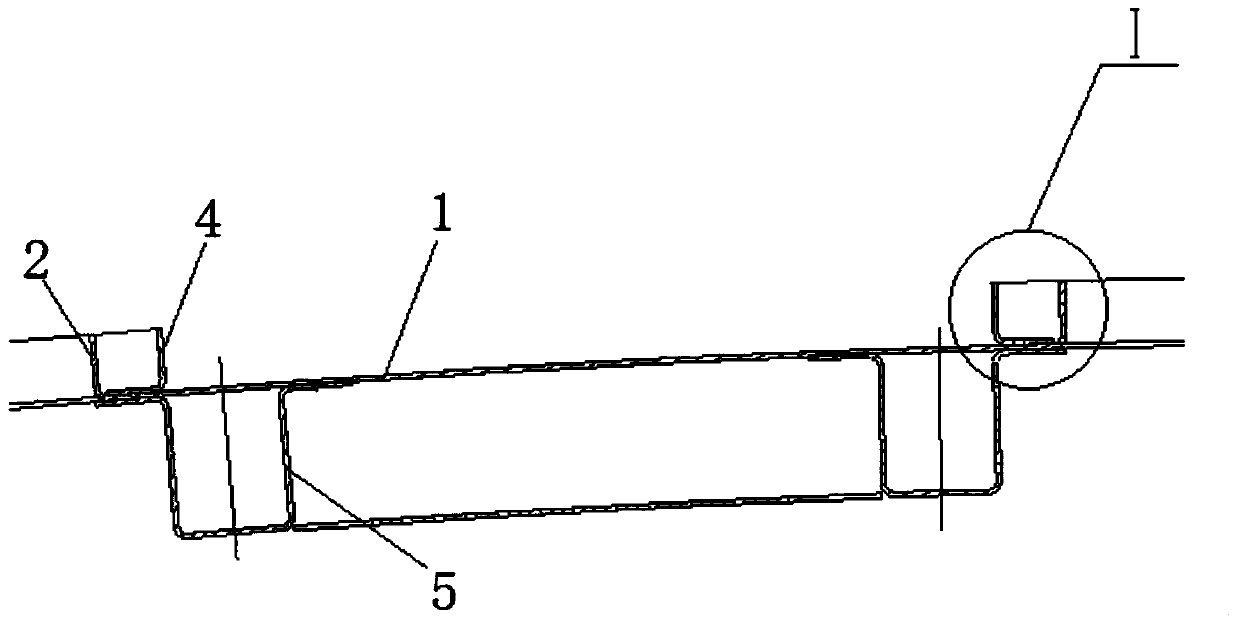

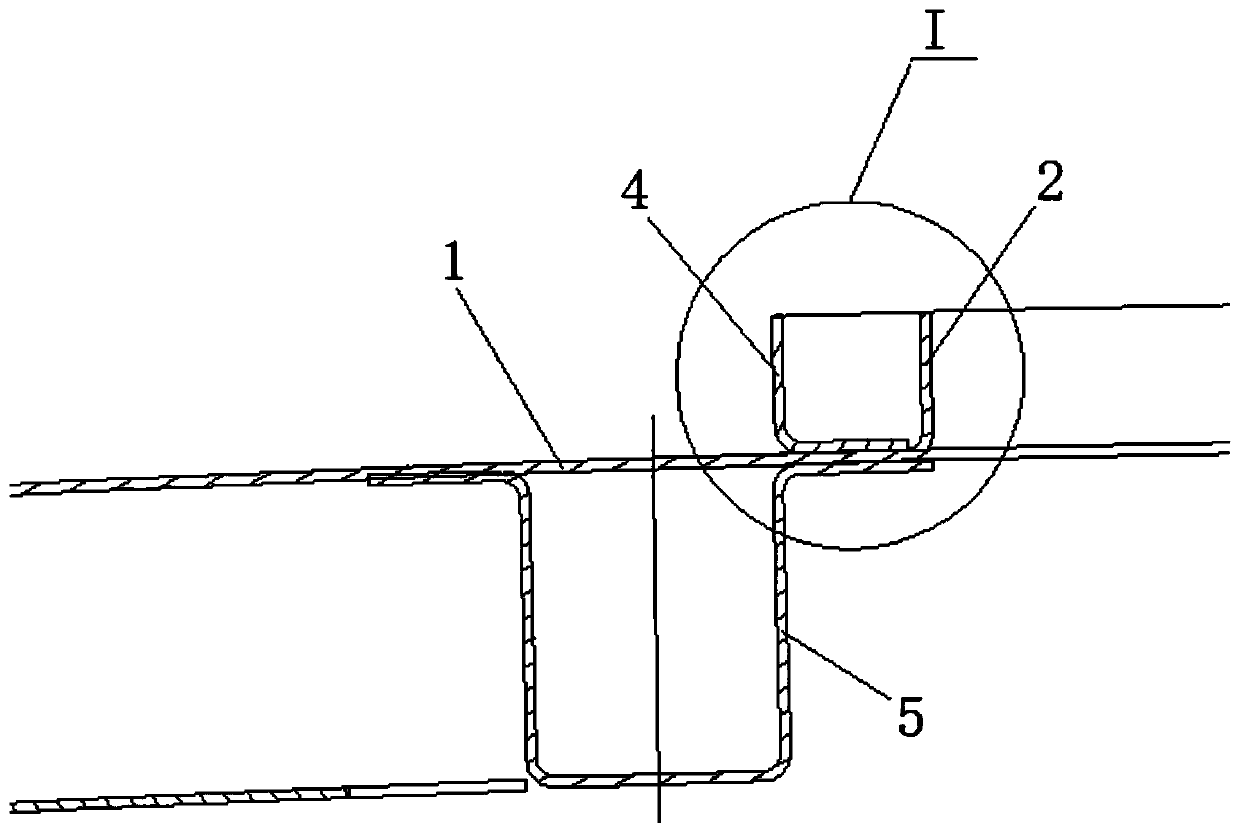

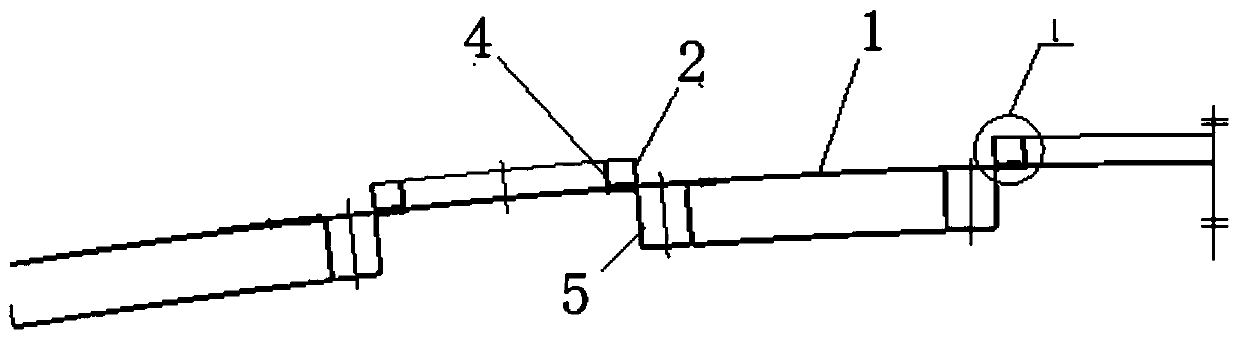

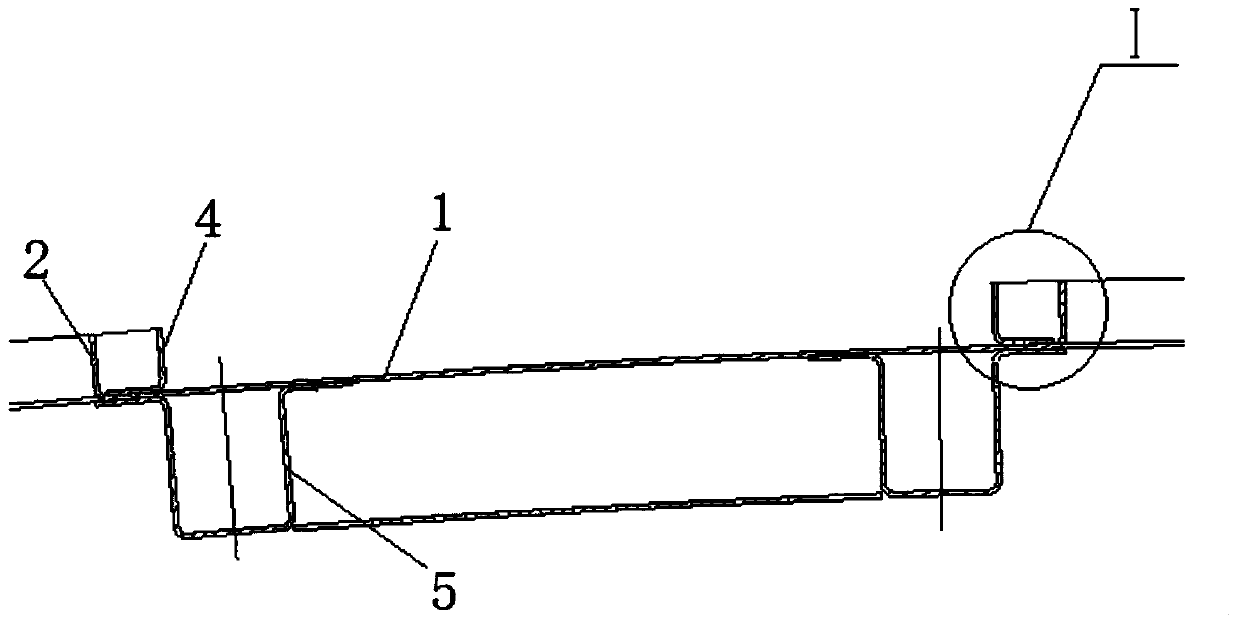

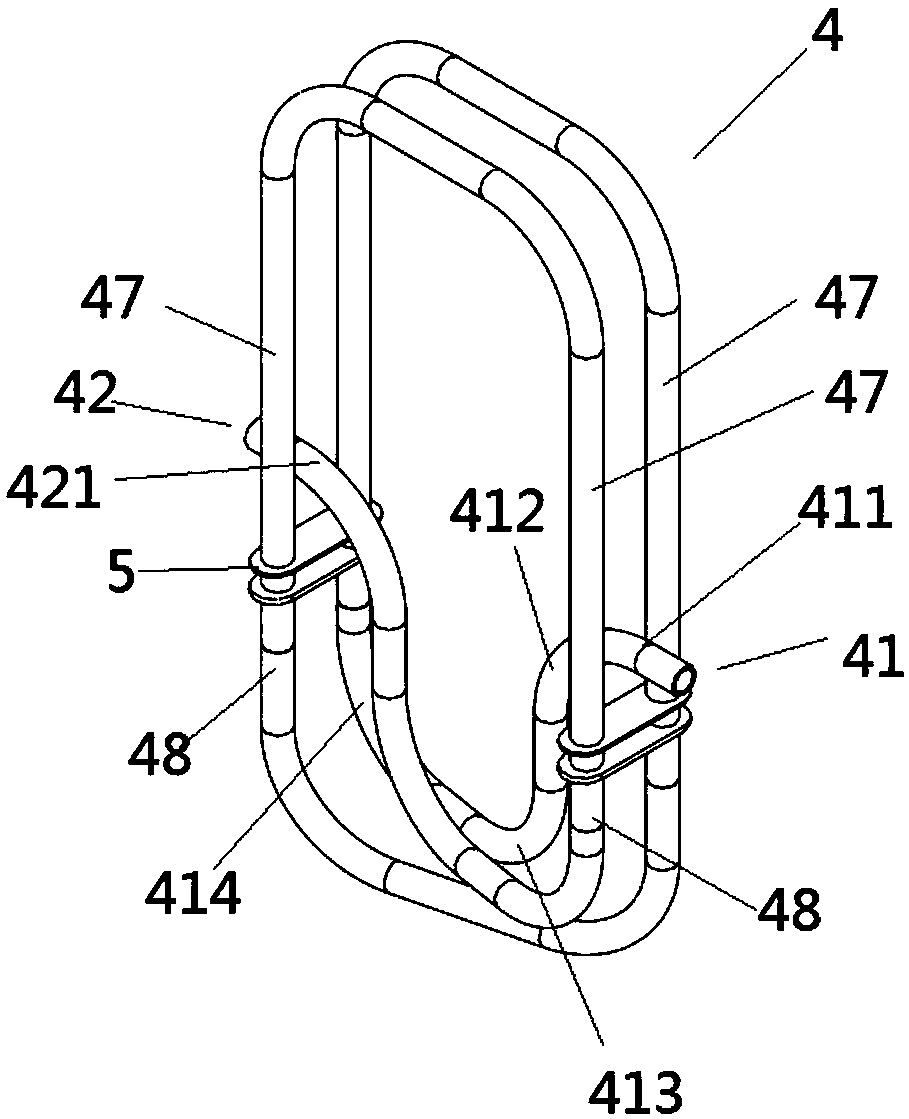

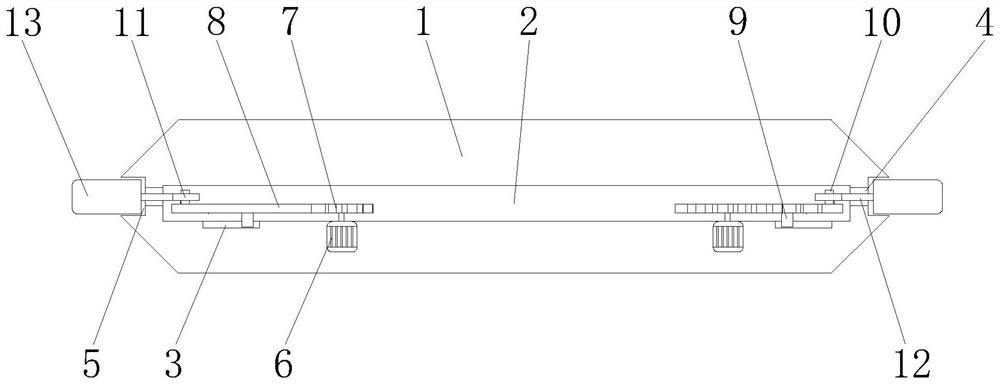

Novel electric tricycle frame

InactiveCN104709409ASimple structural designImprove structural strengthCyclesVehicle frameEngineering

The invention relates to a novel electric tricycle frame. The novel electric tricycle frame comprises a U-shaped main framework (12) formed by bending one pipe, bent portions are formed in the middle of the main framework (12) in a compression mode, the main framework (12) is divided into a front framework body and rear framework bodies, and the front framework body is lower than the rear framework bodies in the vertical direction, so that a step shape is formed. A tail crossbeam (2) is erected between the tail ends of the rear framework bodies in a fixedly connected mode, and a first middle crossbeam (4) is erected between the middles of the rear framework bodies in a fixedly connected mode. The novel electric tricycle frame further comprises a main crossbeam (6) formed by bending one pipe, the middle of the main crossbeam (6) is located in the front framework body of the main framework (12) and fixedly connected with the front framework body of the main framework (12) through a head crossbeam (14), the rear end of the main crossbeam (6) is bent upwards and fixedly connected with the middle of the first middle crossbeam (4), the front end of the main crossbeam (6) is bent and extends obliquely, forwards and upwards to form a front oblique beam, and the top end of the front oblique beam is fixedly connected with a front forked pipe (10).

Owner:TIANJIN DAAN ELECTRIC TRICYCLE

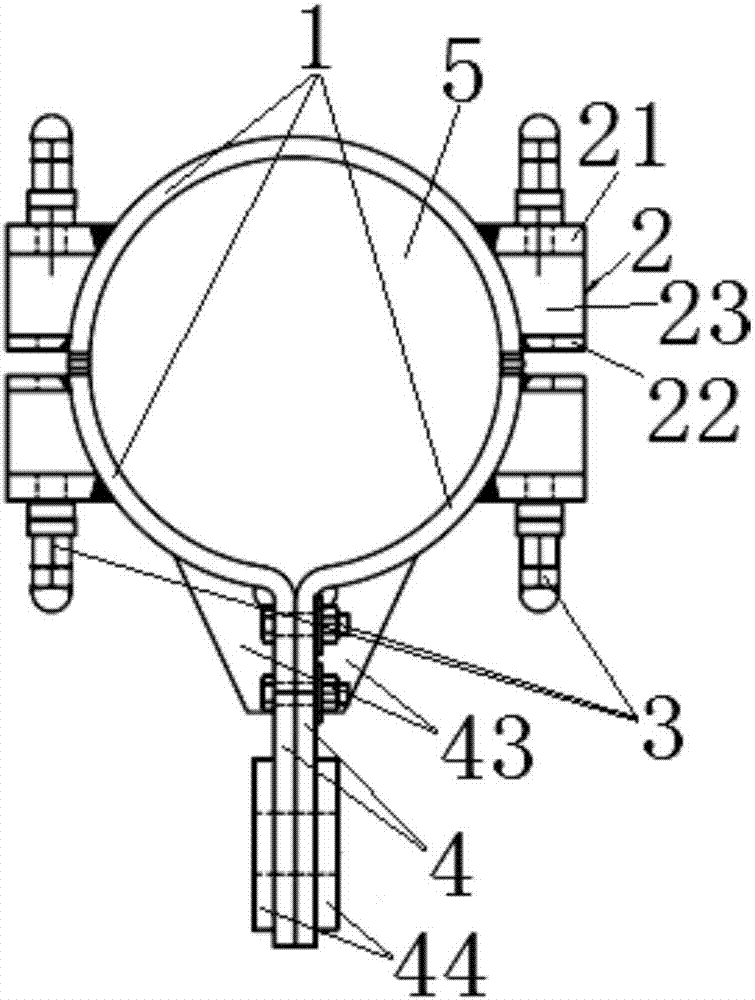

All-welded cable clamp

PendingCN107217595AThe stress structure is stable and reliableUniform mechanical propertiesBridge structural detailsClassical mechanicsStructural engineering

An all-welded cable clamp is provided with a plurality of arc-shaped plates formed by steel plates, wherein the arc-shaped plates are sequentially combined and connected in the peripheral direction to form a cable hole in a surrounding manner; edges of at least two arc-shaped plates are connected in the peripheral direction; connecting lugs formed by steel plates are respectively arranged on outer walls of the two arc-shaped plates of which the edges are connected in the peripheral direction; each connecting lug mainly comprises an outer pressure-bearing plate, an inner pressure-bearing plate and a plurality of supporting rib plates which are welded to the outer wall of the corresponding arc-shaped plate; each outer pressure-bearing plate and the corresponding inner pressure-bearing plate are elongated, are separated from each other in the peripheral direction of the corresponding arc-shaped plate, and are welded to the outer wall of the corresponding arc-shaped plate in the length direction of the arc-shaped plate; the welded position of each inner pressure-bearing plate is close to the peripheral connected edge of the corresponding arc-shaped plate; the supporting rib plates of each connecting lug are successively separated from one another in the length direction of the corresponding arc-shaped plate, are arranged on the outer wall of the corresponding arc-shaped plate, and are positioned between the corresponding outer pressure-bearing plate and the corresponding inner pressure-bearing plate; three sides of each supporting rib are welded with the corresponding outer pressure-bearing plate, the corresponding arc-shaped plate and the corresponding inner pressure-bearing plate; and a plurality of bolt holes which correspond in pairs are formed in parts, which are staggered from the corresponding supporting rib plates, of each outer pressure-bearing plate and each inner pressure bearing plate.

Owner:DEYANG TIANYUAN HEAVY IND

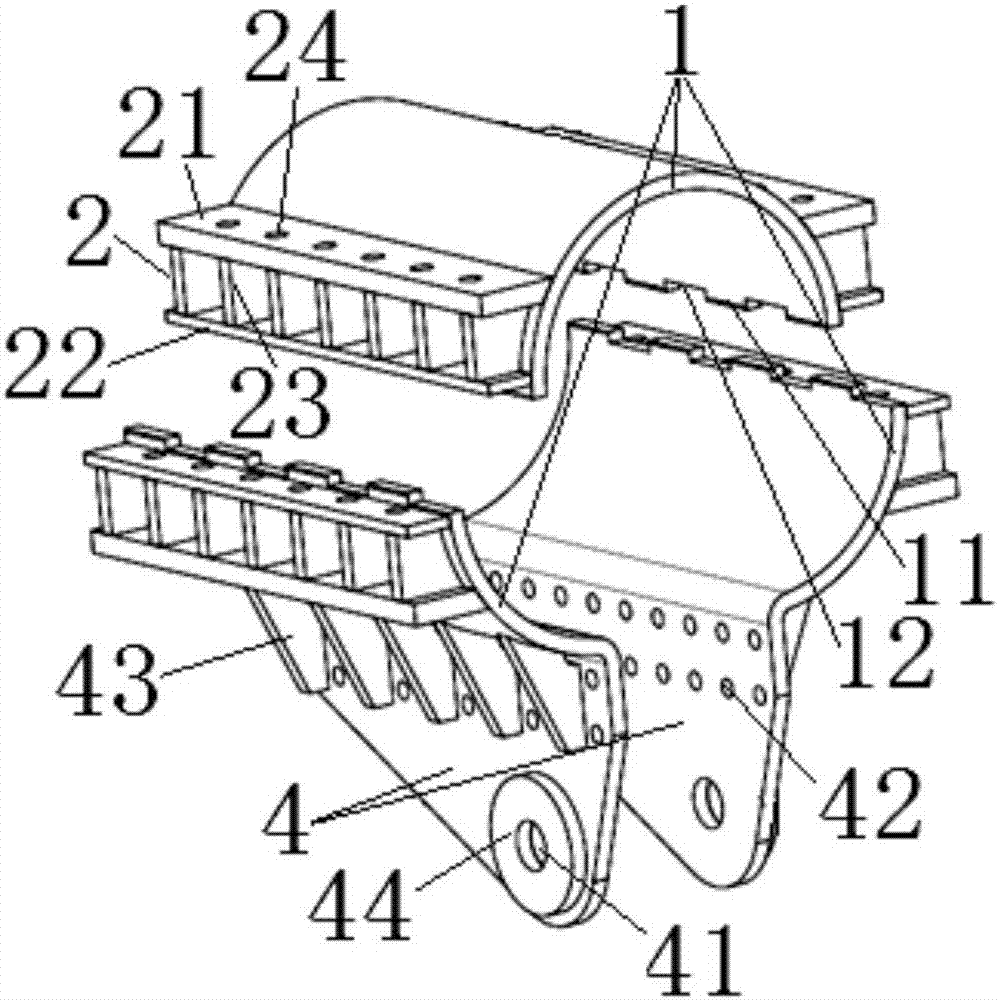

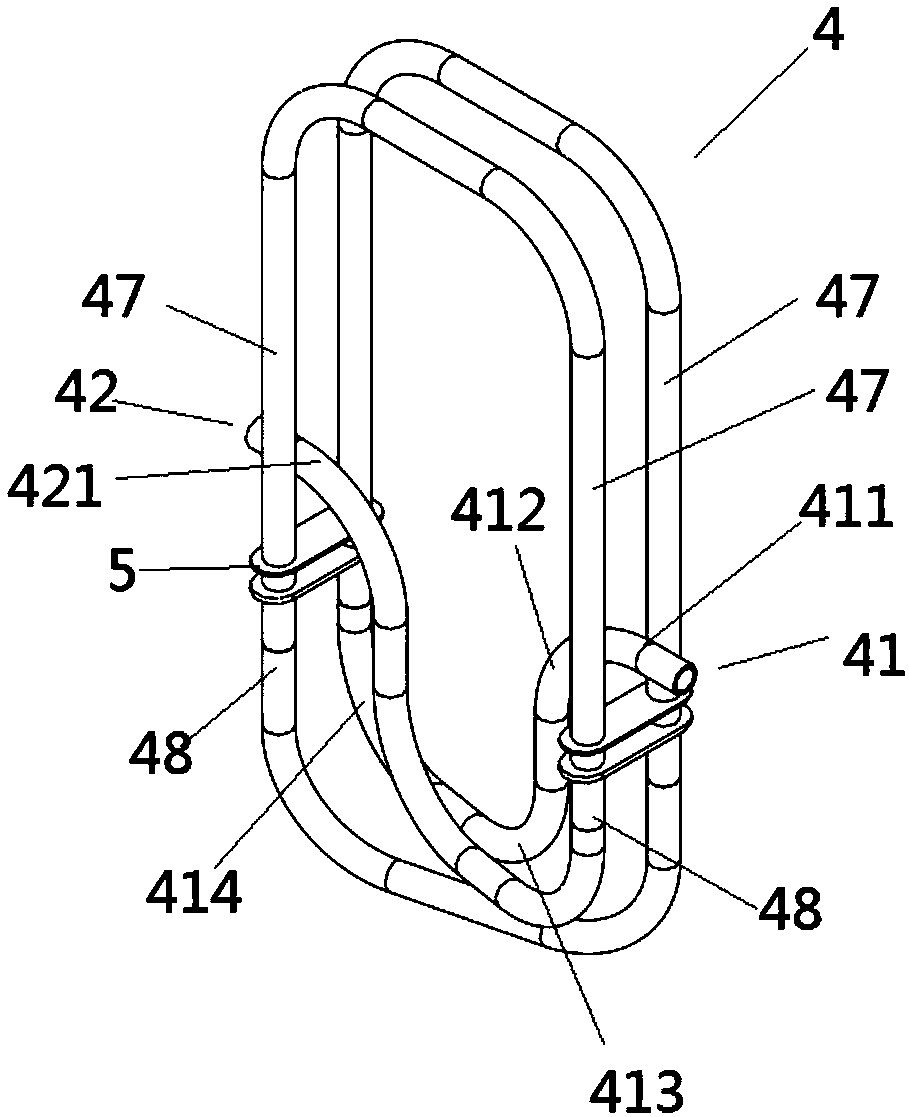

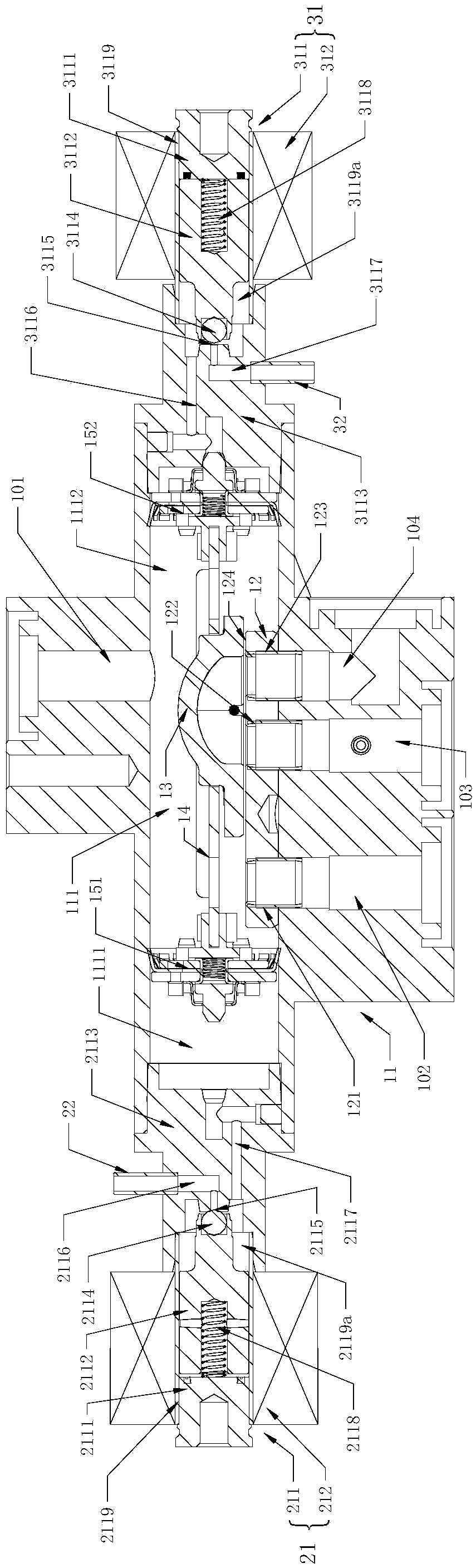

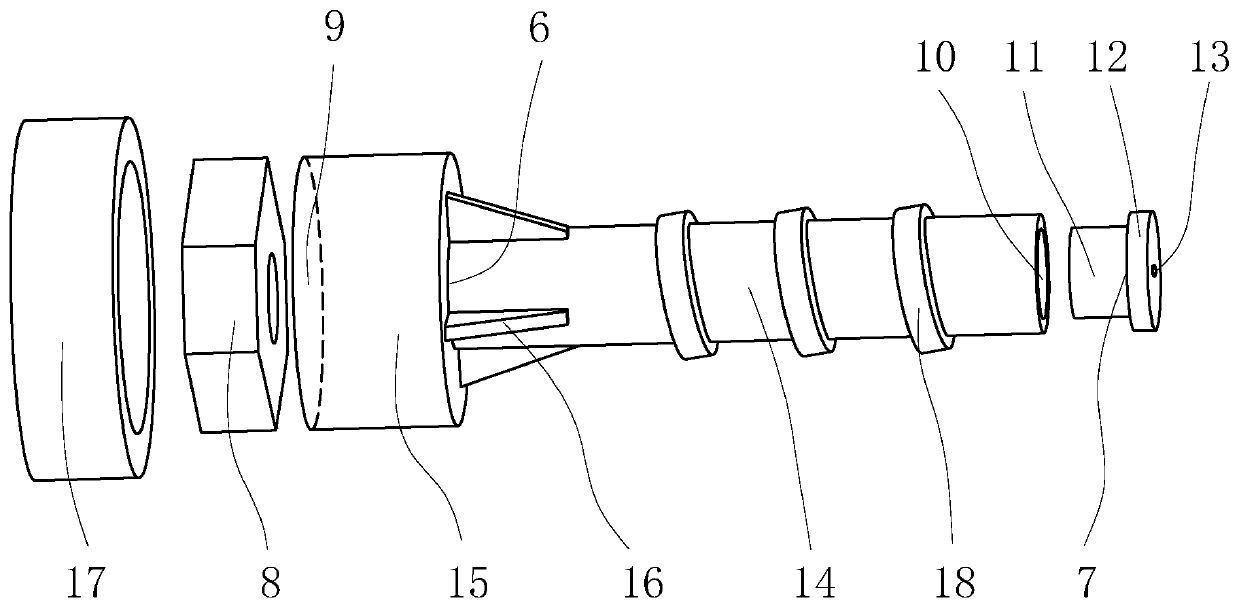

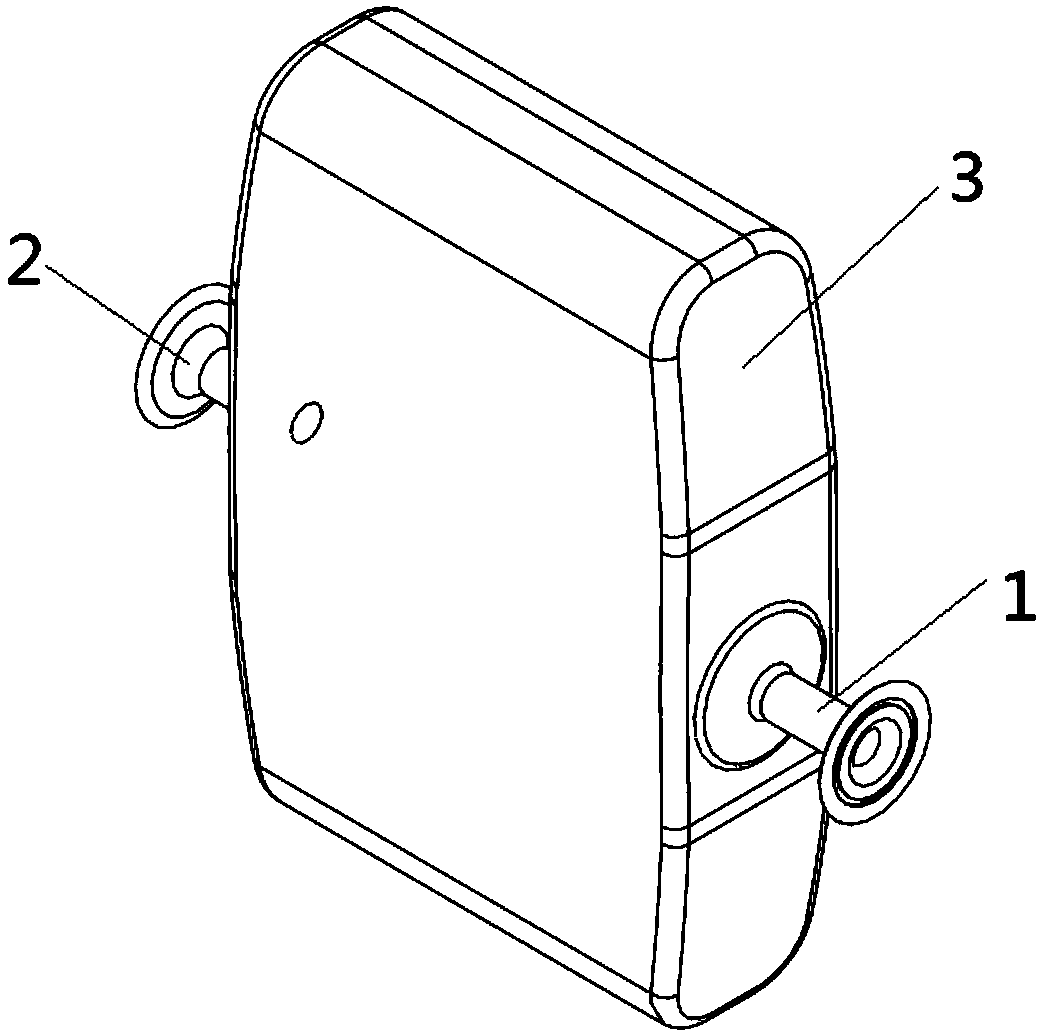

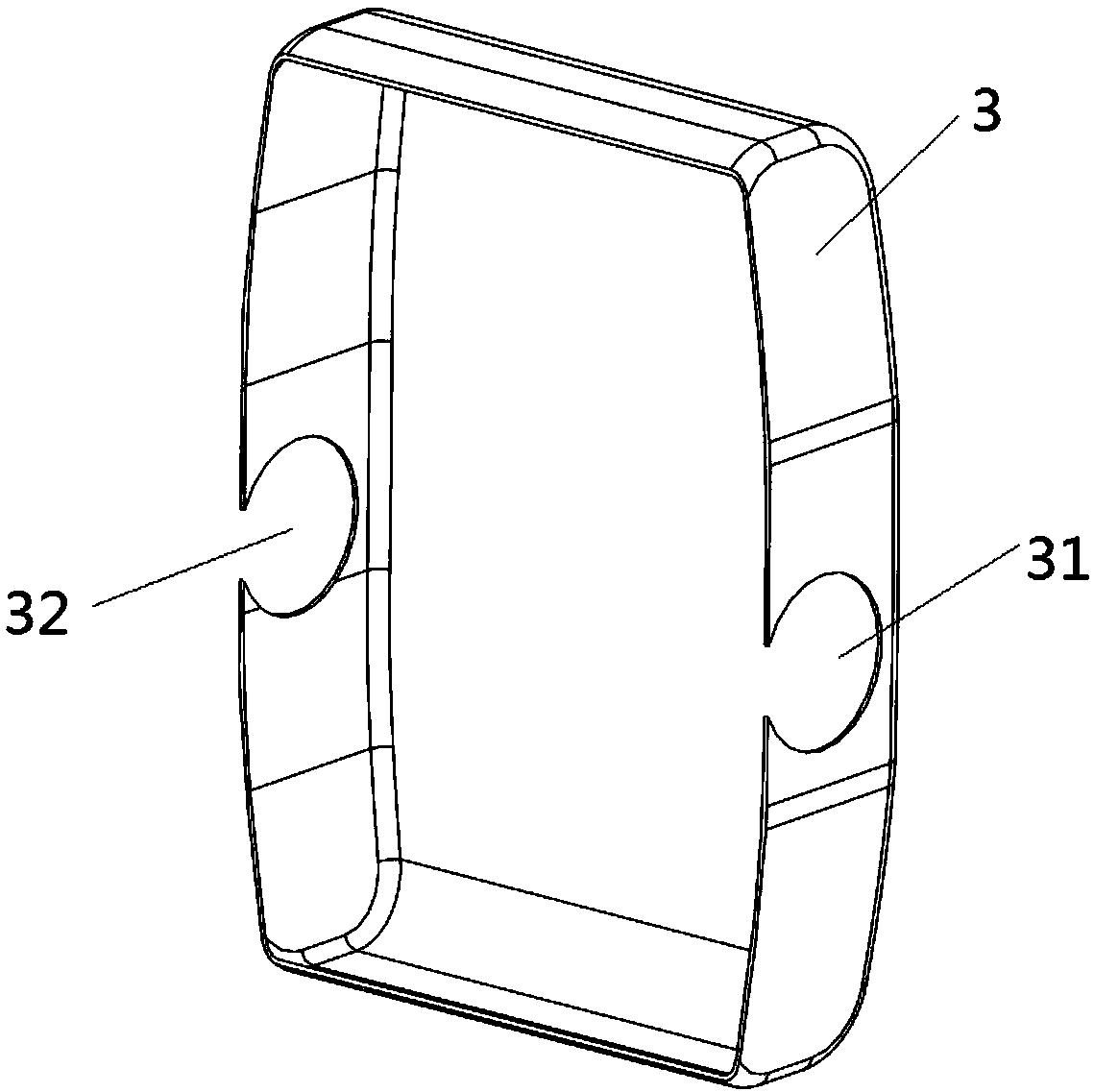

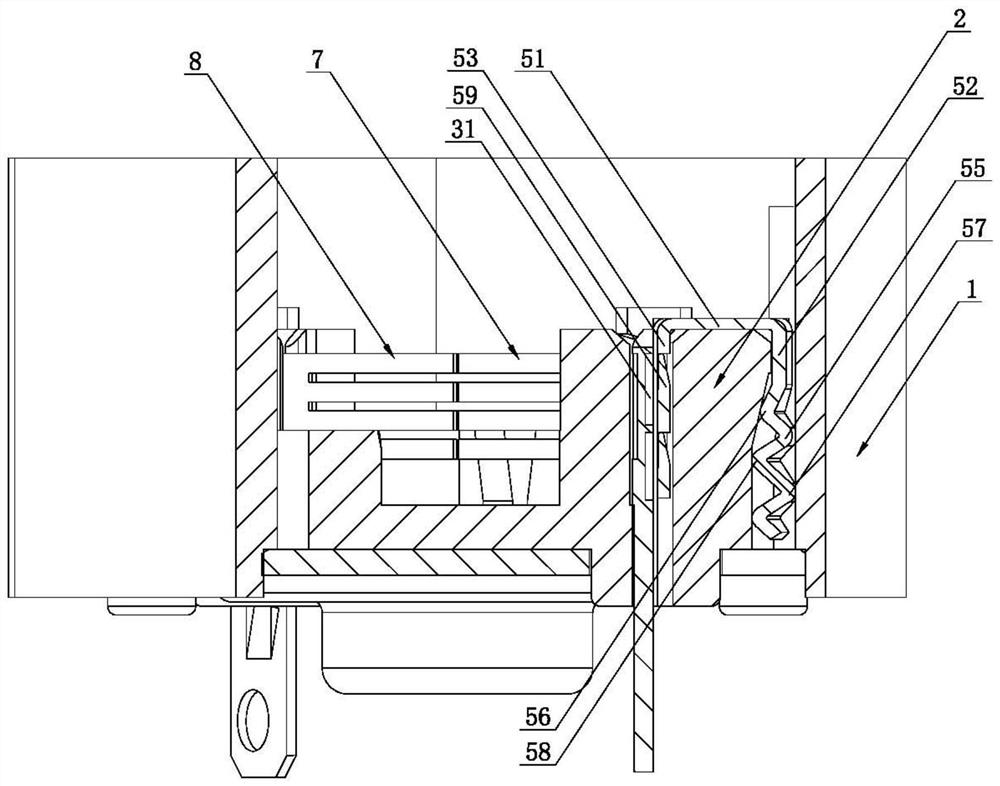

Coriolis mass flowmeter and sensor assembly thereof

PendingCN109425399AReduce distanceWon't turnVolume meteringDirect mass flowmetersEngineeringVibration isolation

The invention discloses a sensor assembly for a Coriolis mass flowmeter. The flowmeter includes an upstream pipeline connector used for being connected to an upstream fluid pipeline and a downstream pipeline connector used for being connected to a downstream fluid pipeline. The axis of the upstream pipeline connector and the axis of the downstream pipeline connector are positioned on one central axis; the sensor assembly is arranged in a shell of the flowmeter and comprises a vibration part and a non-vibration part which are separated by a vibration isolation structure; the vibration isolationstructure at least includes a first vibration isolation piece which divides the fluid flow pipe into a vibration pipeline and a non-vibration pipeline, and the first vibration isolation piece is close to a central axis. By arranging the first vibration isolation piece close to the central axis, the distance between the first vibration isolation piece and the upstream and downstream pipeline connectors is short; if vibration leaks from the vibration part, correspondingly the distance between an exciting force formed on a vibration isolation sheet and an upstream and downstream junction is short, and the flowmeter cannot rotate because of eccentricity of the exciting force.

Owner:罗凡

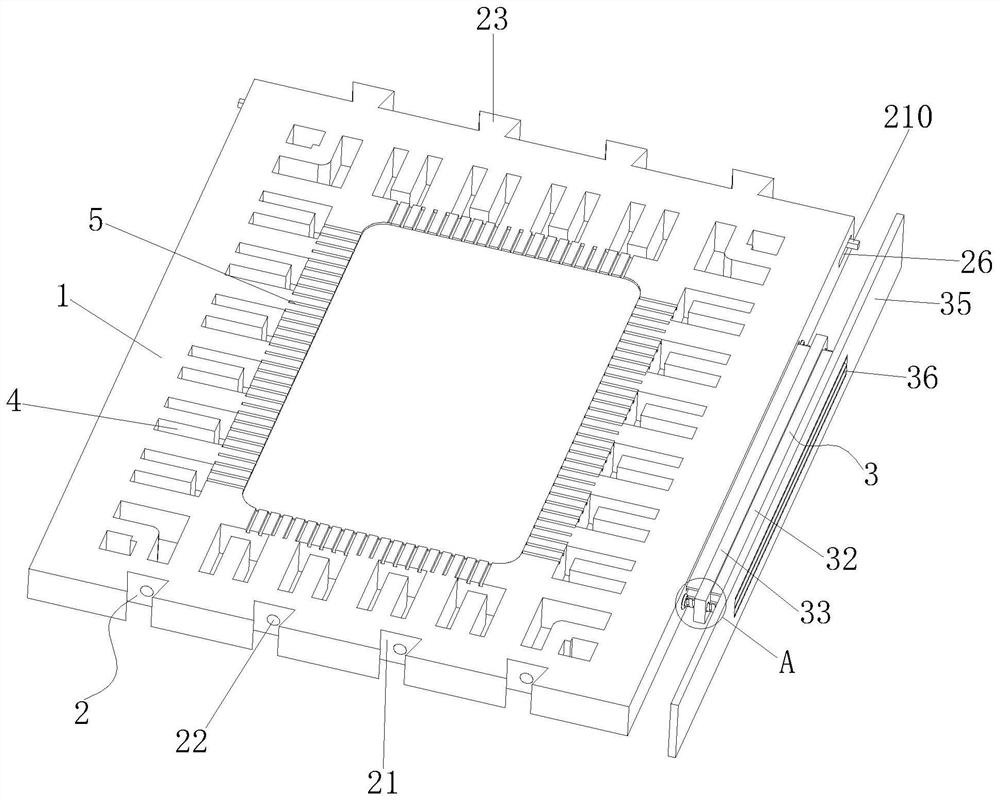

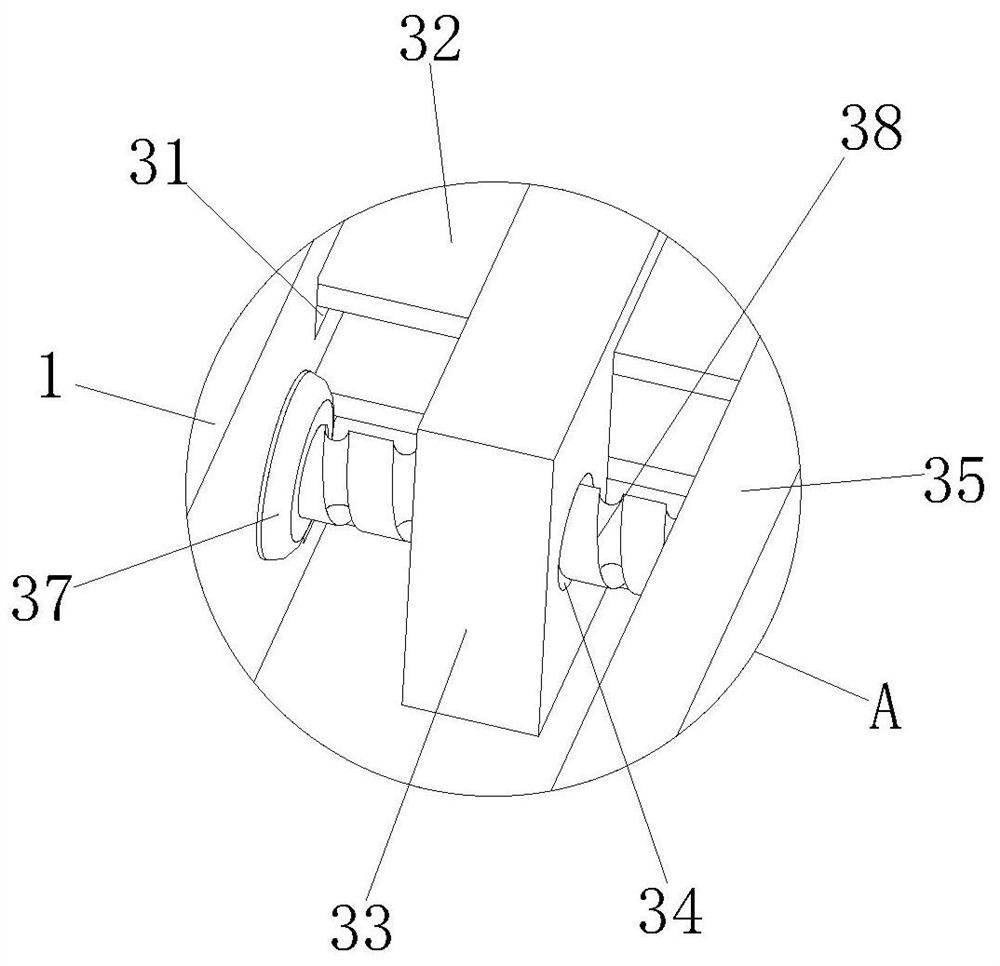

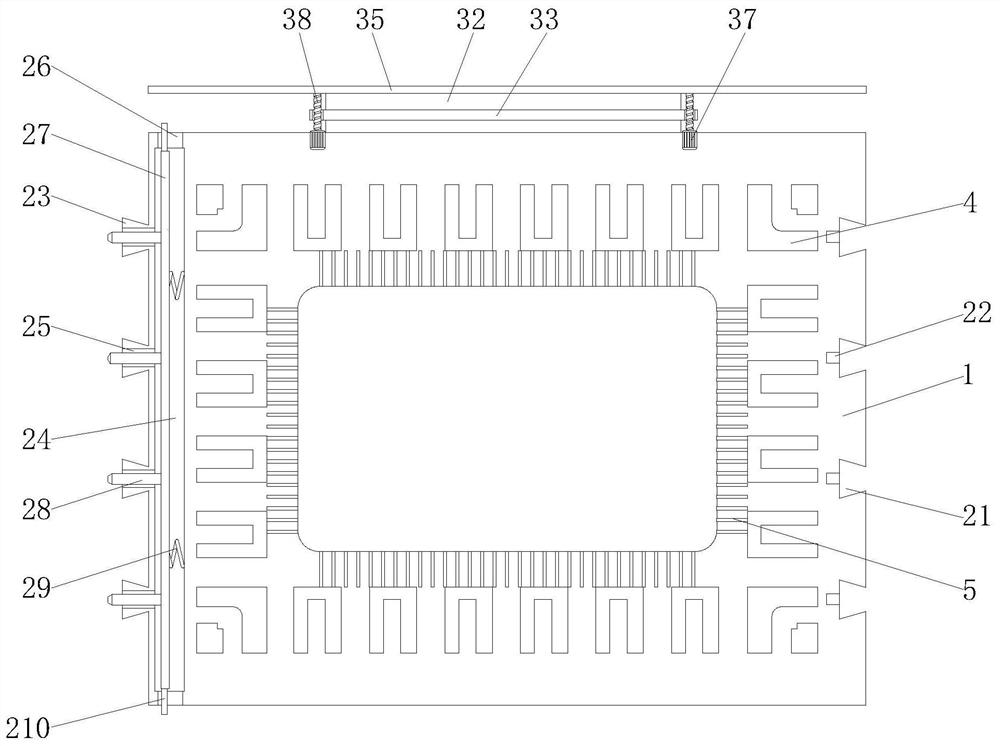

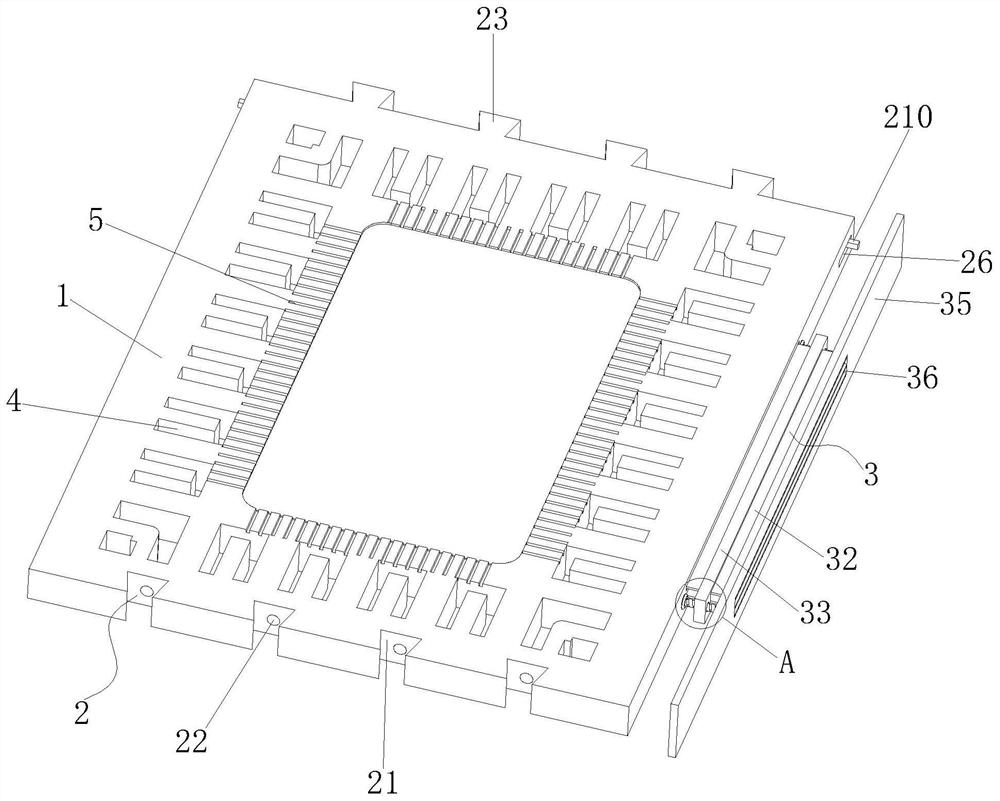

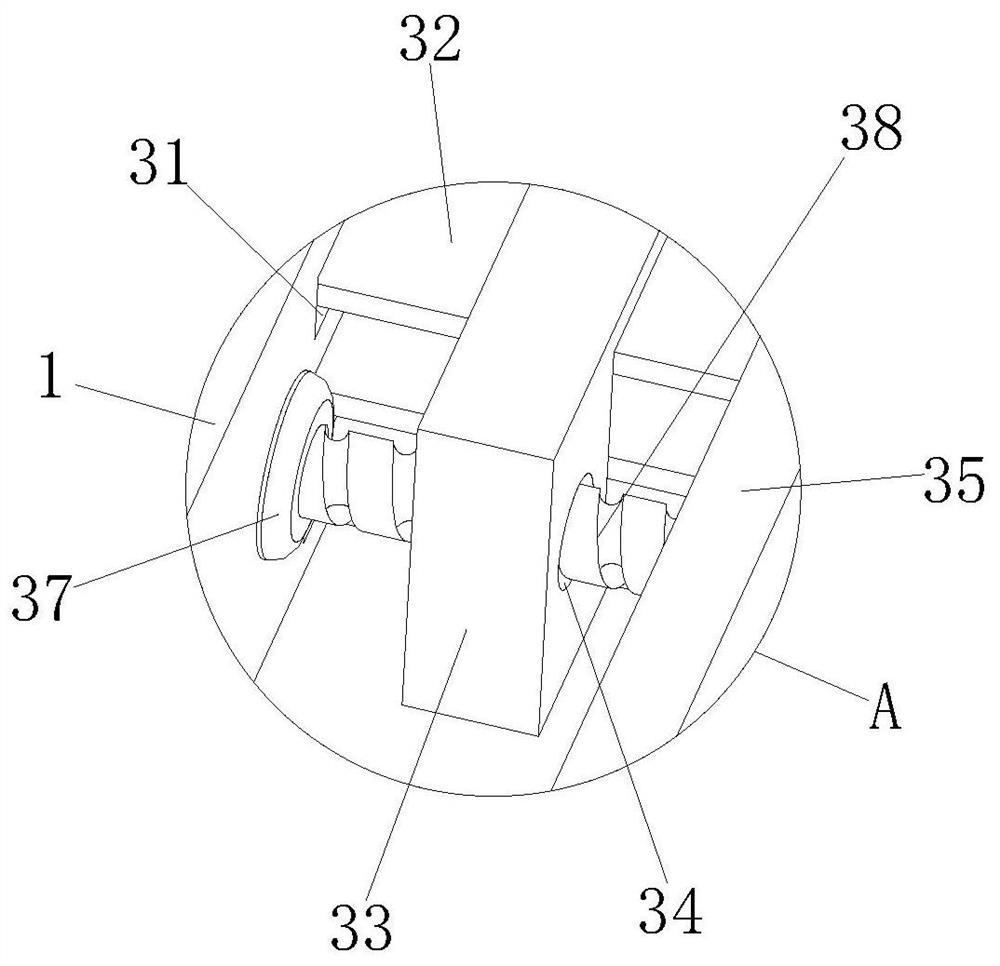

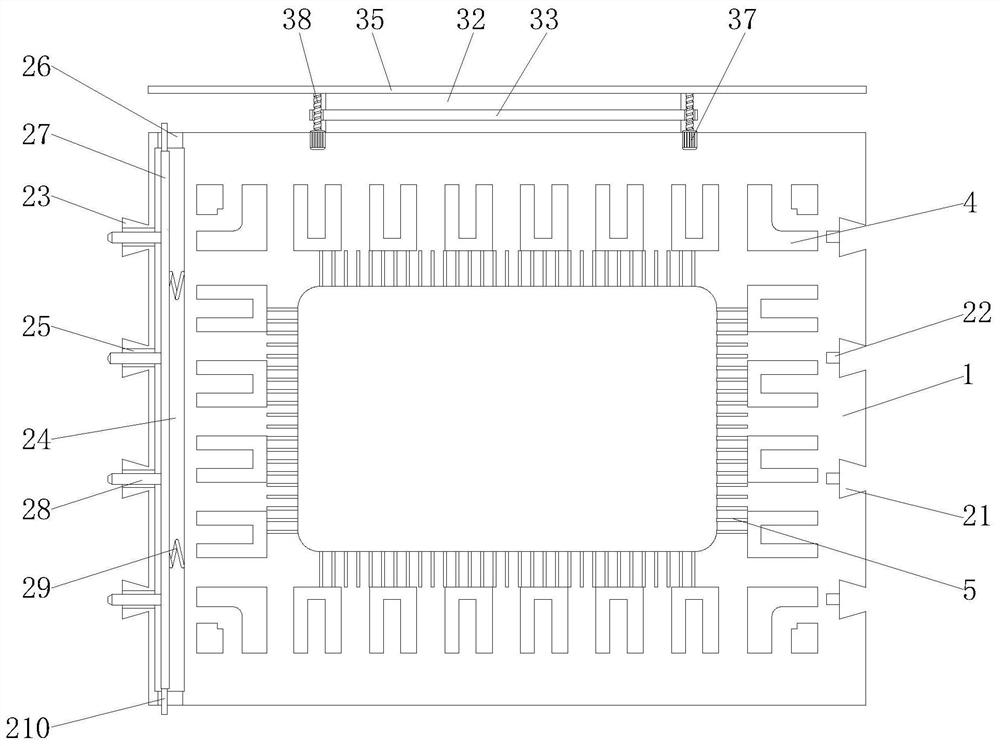

Lead frame of high-power driving circuit and production method

ActiveCN112216668AAvoid it happening againProtect healthSemiconductor/solid-state device detailsSolid-state devicesLead frameMechanical engineering

The invention discloses a lead frame of a high-power drive circuit and a production method, and the lead frame comprises a lead frame main body, a splicing assembly is fixed in one side of the lead frame main body, and a heat dissipation assembly is fixed outside one side of the lead frame main body; the splicing assembly comprises clamping blocks distributed and welded to the side face of one side of the lead frame body, clamping grooves corresponding to the clamping blocks are distributed in one side of the lead frame body, a moving groove is formed in one side of the lead frame body, and aconnecting plate is installed in one side of the moving groove. According to the invention, splicing operation can be rapidly carried out, so that a plurality of lead frame main bodies are fixedly connected, the welding operation can be reduced, a lot of harmful gases are prevented from being generated in the welding process, the environment can be effectively protected, the human health is protected, the potential safety hazard is reduced, and continuous heat conduction and heat dissipation can be carried out; the heat in the lead frame main body is rapidly dissipated, and the heat dissipation efficiency is improved.

Owner:ANHUI LONGXINWEI TECH CO LTD

Coriolis mass flowmeter and sensor assembly thereof

PendingCN109425395AImprove stabilitySmall turning radiusVolume meteringDirect mass flowmetersGravity centerEngineering

The invention discloses a sensor assembly for a Coriolis mass flowmeter. The flowmeter includes an upstream pipeline connector used for being connected to an upstream fluid pipeline and a downstream pipeline connector used for being connected to a downstream fluid pipeline. The axis of the upstream pipeline connector and the axis of the downstream pipeline connector are positioned on one central axis; the sensor assembly is arranged in a shell of the flowmeter and comprises a vibration part and a non-vibration part which are separated by a vibration isolation structure, and the gravity centerof the sensor assembly is basically positioned on the central axis. By positioning the gravity center of the sensor assembly basically on the central axis, when vibration leakage happens at the vibration part, since the gravity center of the sensor assembly is as close as possible to the central axis of the upstream and downstream pipeline connectors or is positioned on the central axis of the upstream and downstream pipeline connectors, the rotation radius of a sensor about the axis of an upstream and downstream junction is decreased. Therefore, no matter what causes vibration leakage of thevibration part of the sensor, vibration of the non-vibration part of the whole sensor is unlikely to happen, and the stability of the flowmeter is improved.

Owner:罗凡

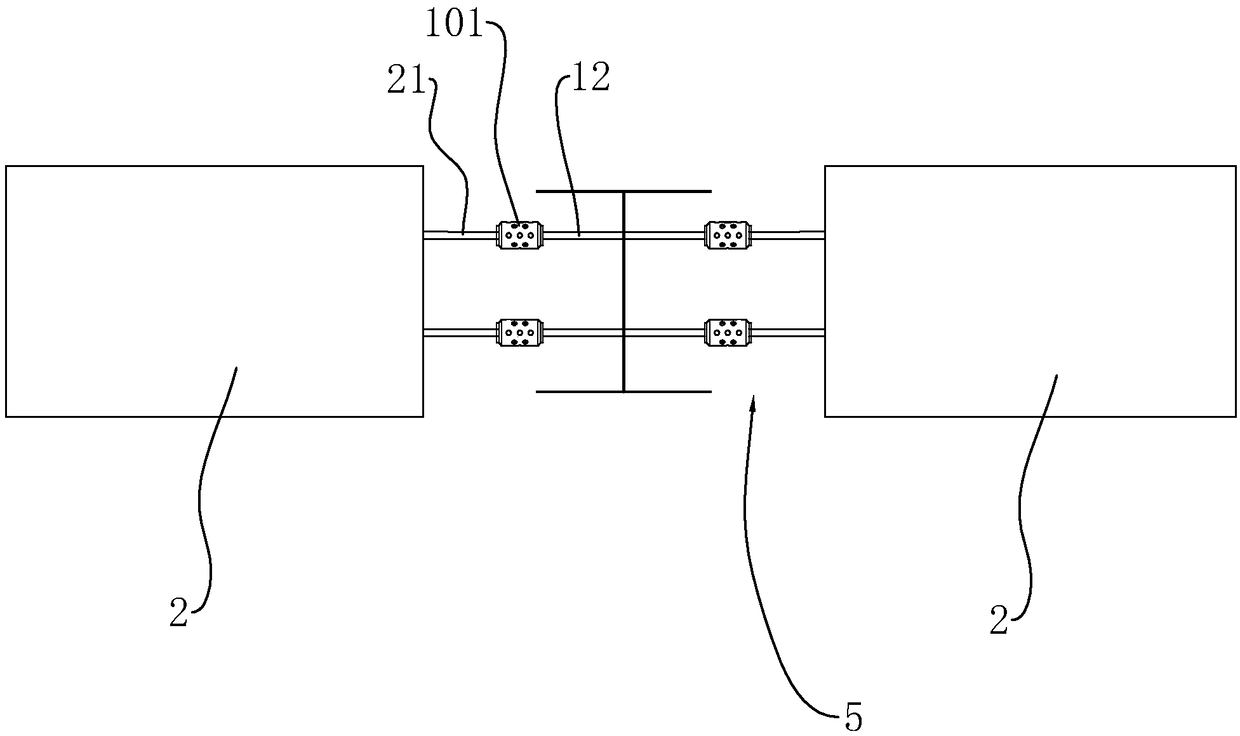

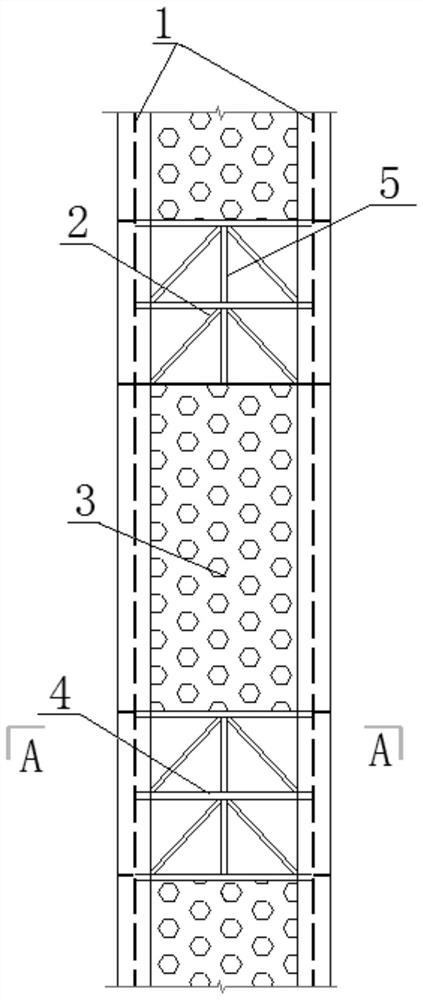

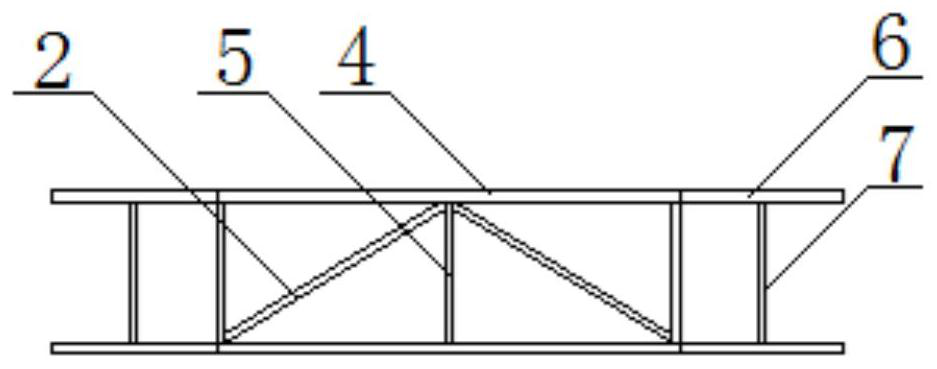

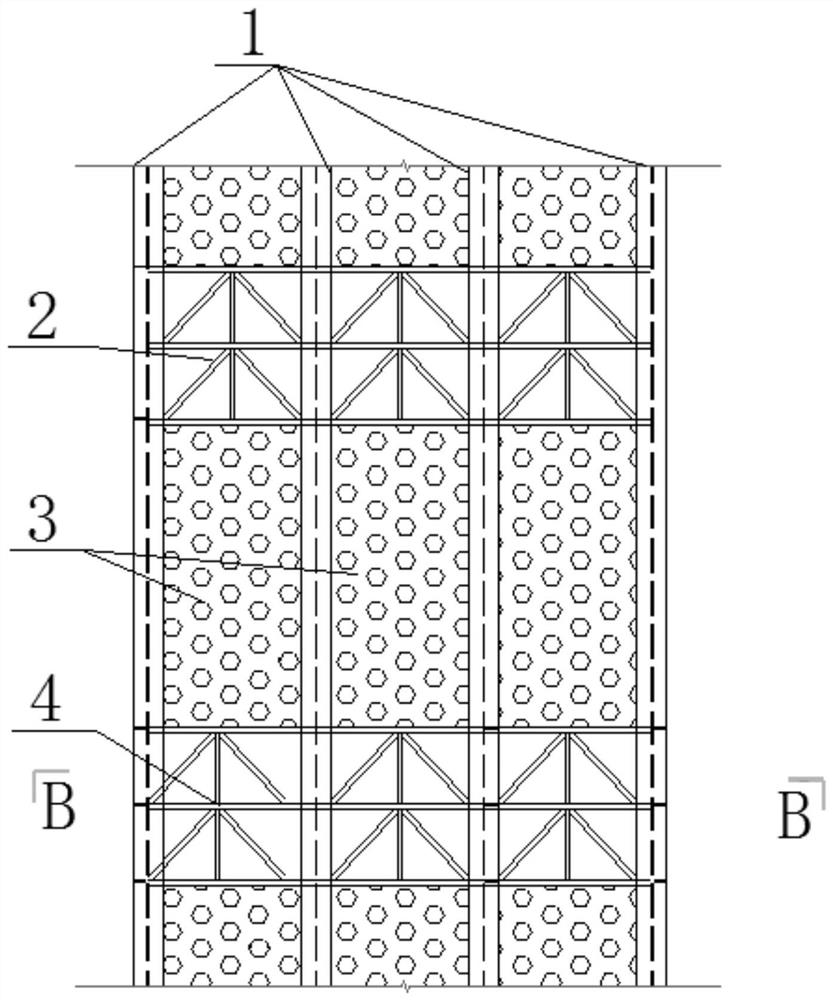

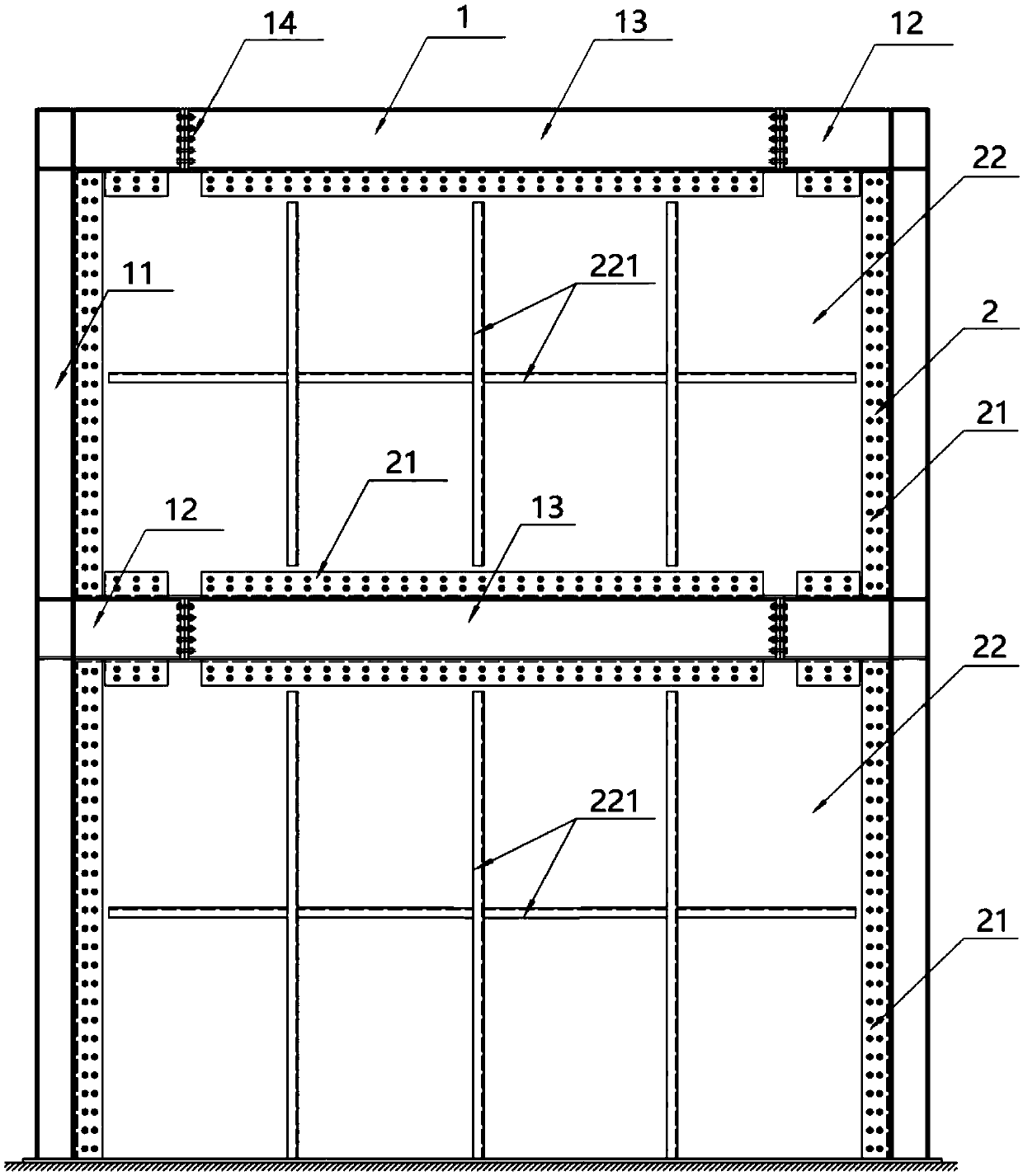

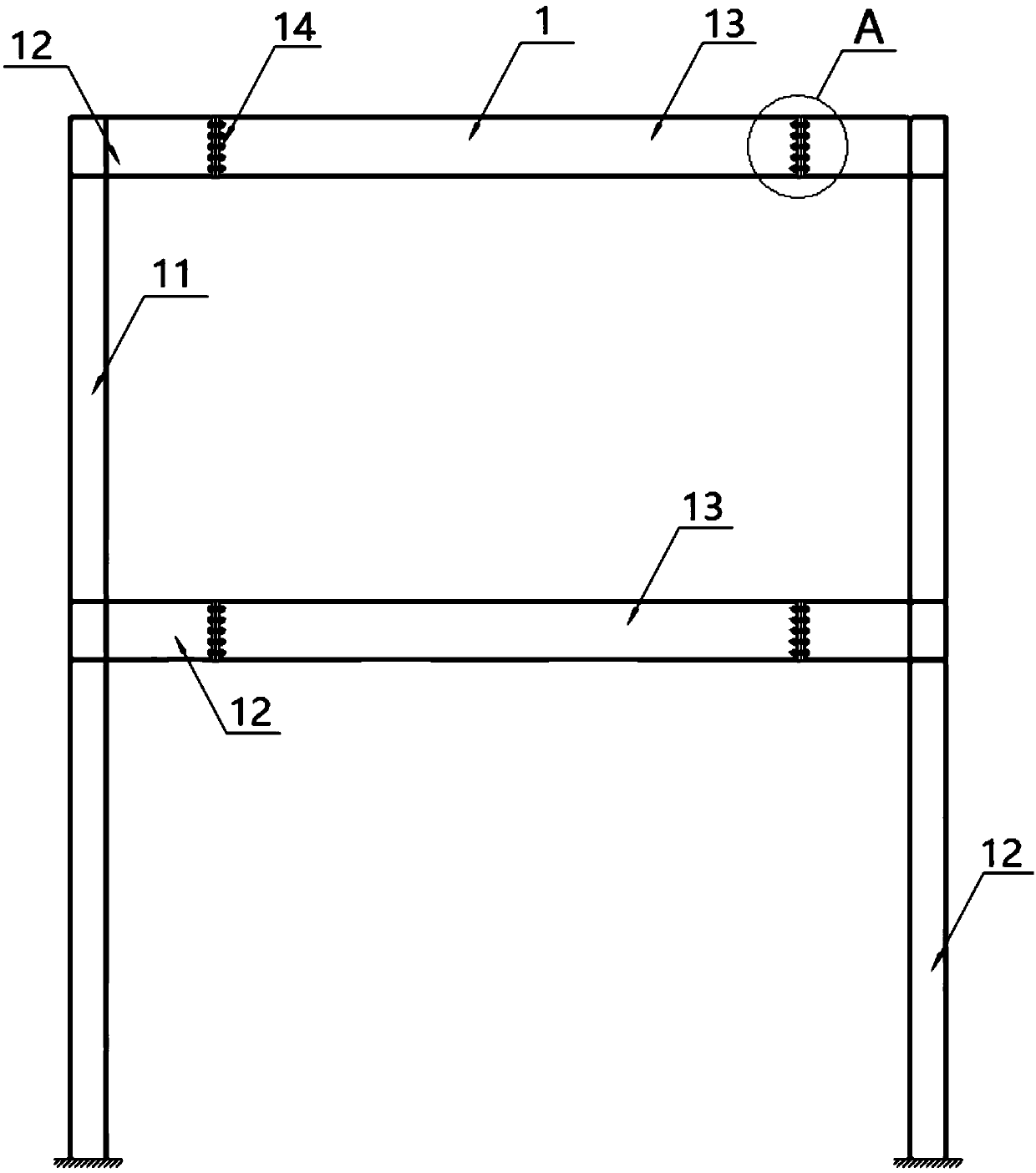

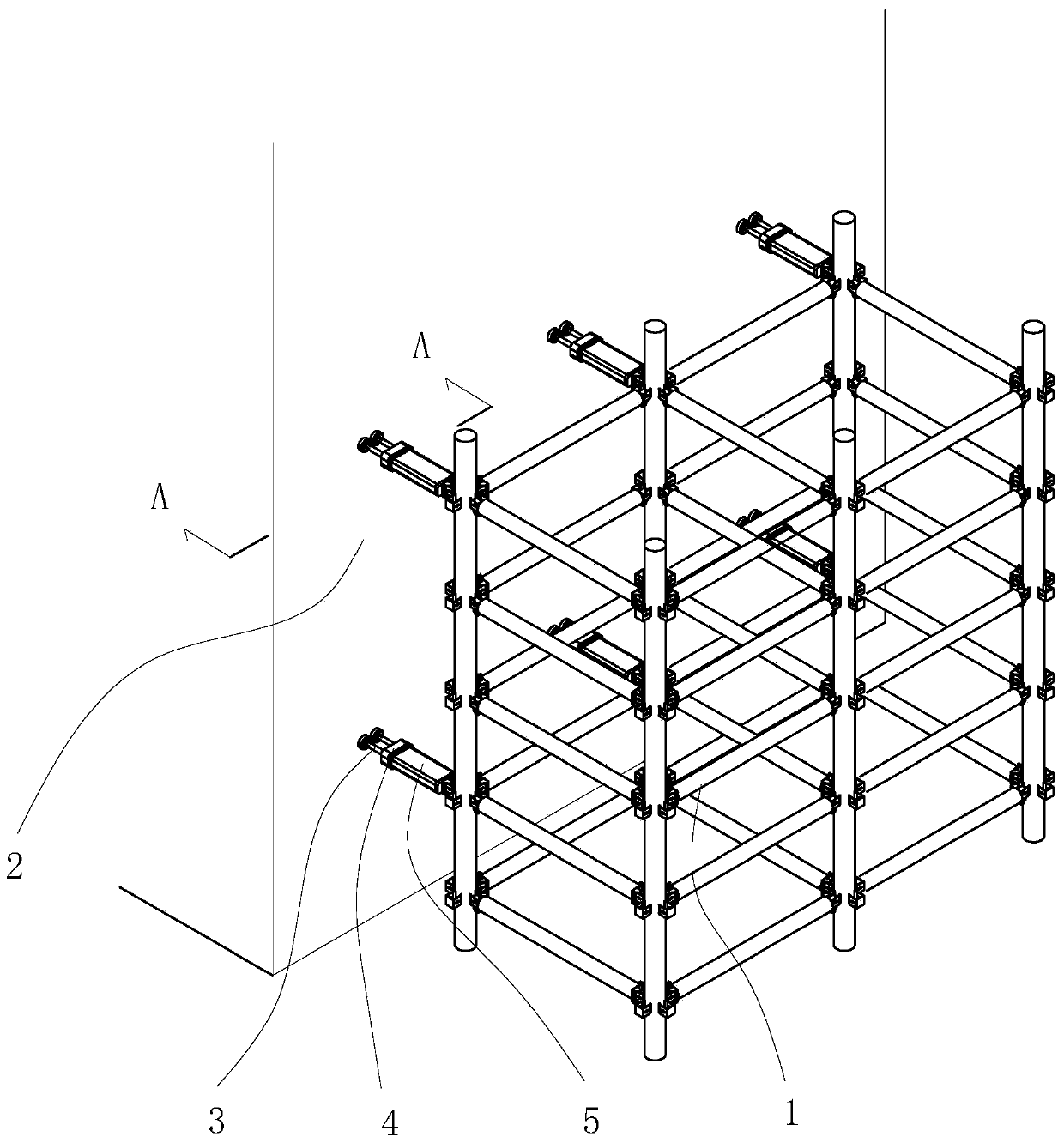

Coupled steel structure

PendingCN112854540AReduce welding operationsShorten the construction periodWallsMechanical engineeringIndustrial engineering

The invention discloses a coupled steel structure. The coupled steel structure comprises at least two stand columns arranged side by side, and the adjacent stand columns are connected through horizontal components. According to the coupled steel structure, the overall size can be set in a factory in advance, the stand columns and the horizontal components are produced and assembled in the factory, and after being transported to a construction site, the stand columns and the horizontal components can be directly used as a wall body, and the stand columns and the horizontal components are not assembled as well after being prefabricated in the factory, and are assembled after being transported to the construction site. According to the coupled steel structure, welding operation during construction is reduced, and the construction period is remarkably shortened.

Owner:HANGXIAO STEEL STRUCTURE

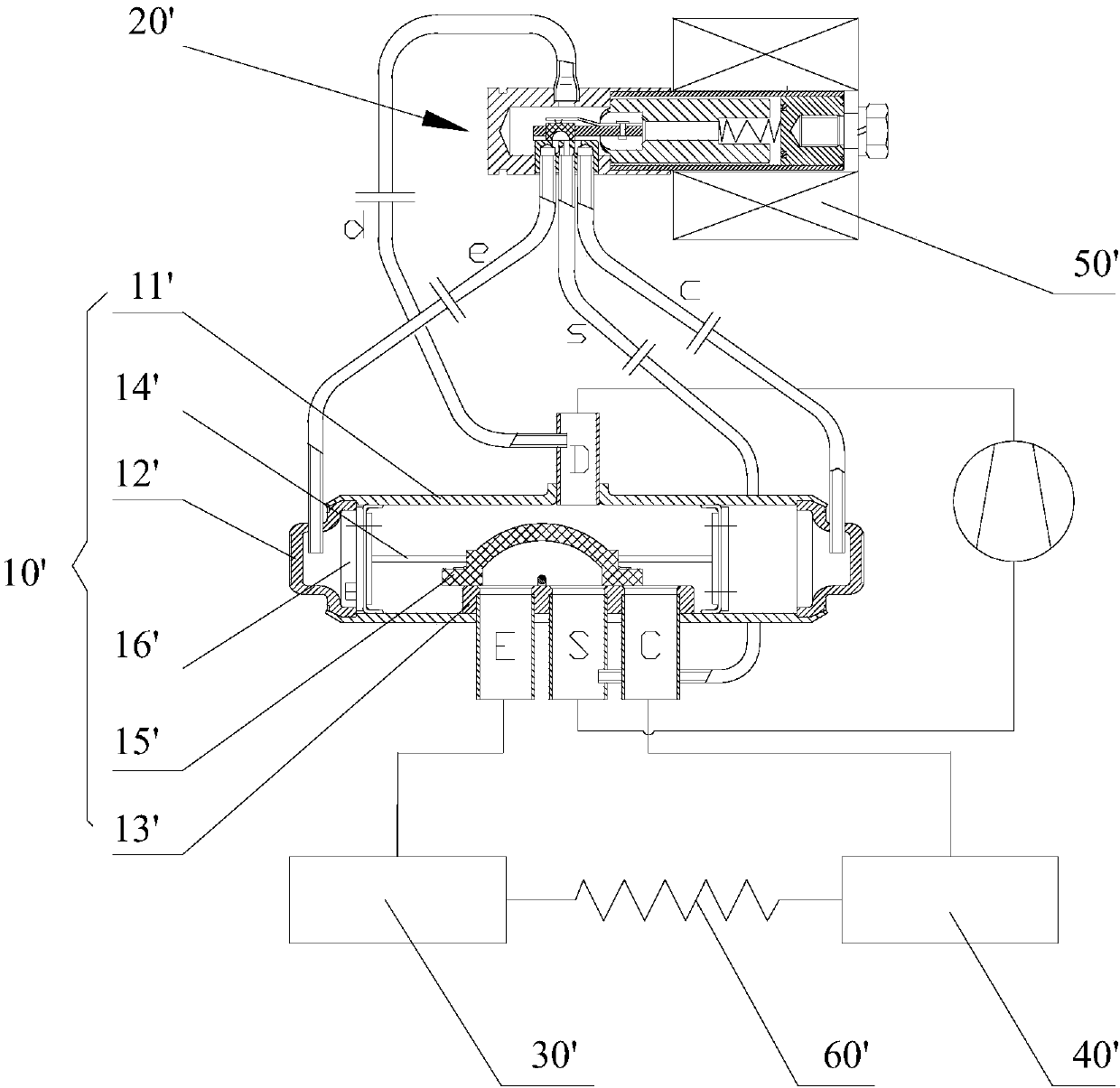

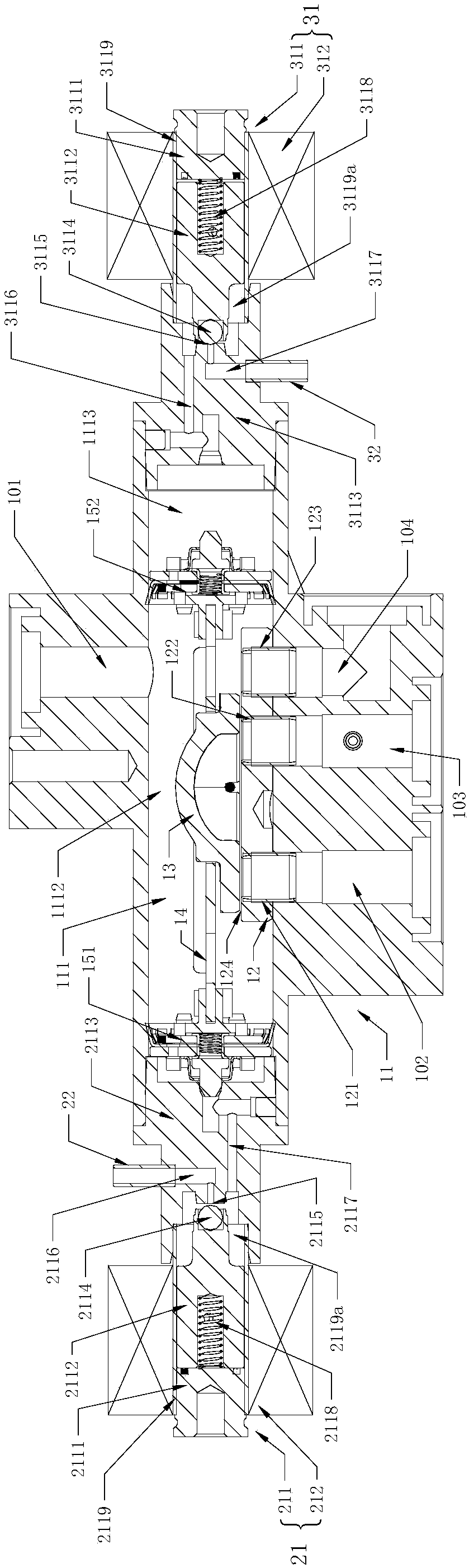

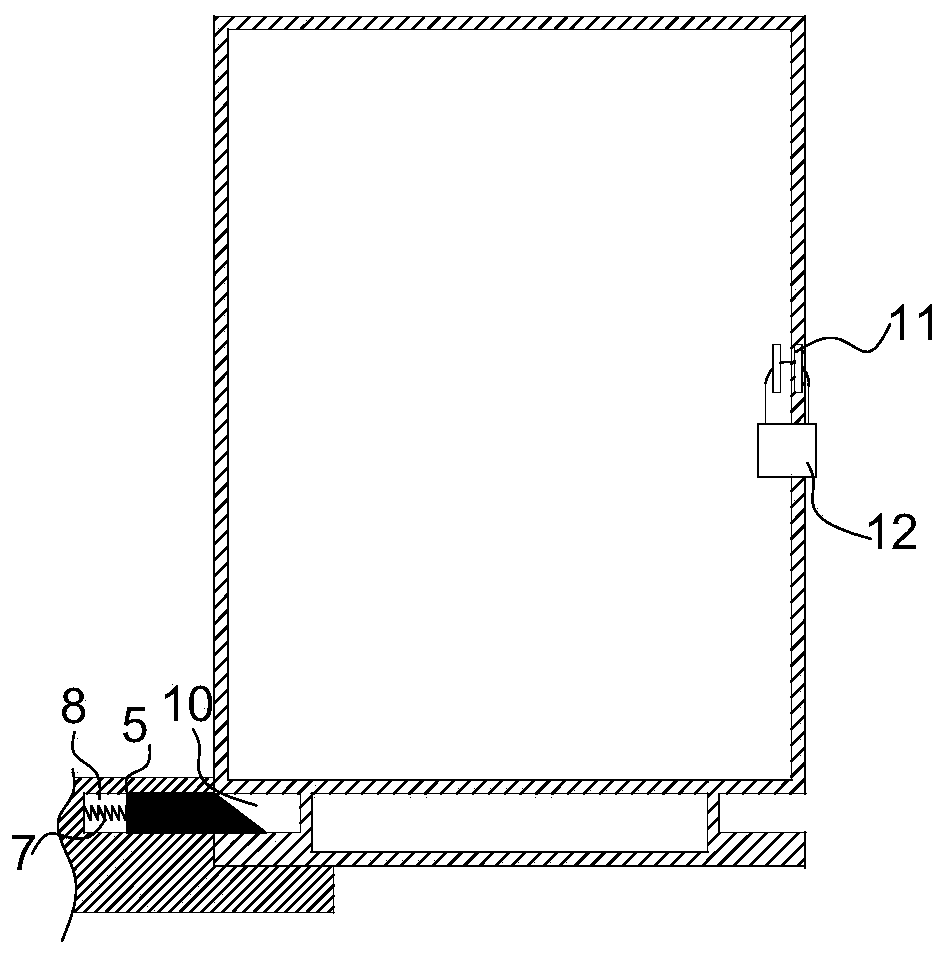

Electromagnetic switching valve

PendingCN109990129AReduce welding operationsReduce vibrationOperating means/releasing devices for valvesMultiple way valvesHigh pressurePilot valve

The invention discloses an electromagnetic switching valve which is characterized by comprising a main valve and a pilot valve, and the pilot valve comprises a first pilot valve and a second pilot valve; the first pilot valve comprises a first valve body and a first coil which are matched with each other; the second pilot valve comprises a second valve body and a second coil which are matched witheach other; the first valve body comprises a first flow guide part, and the second valve body comprises a second flow guide part; the main valve comprises a main valve body, and the main valve body comprises a main valve cavity; two sides, in the central axis direction of the main valve body, of the main valve body are fixedly connected with the first pilot valve and the second pilot valve correspondingly; the first flow guide part and the main valve body are fixed in a press fit and welding mode, and the second flow guide part and the main valve body are fixed in a press fit and welding mode. According to the electromagnetic switching valve provided by the invention, the welding operation of connecting pipes is reduced, and the potential risks that too many welding parts are prone to failure due to high pressure and vibration can be reduced.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

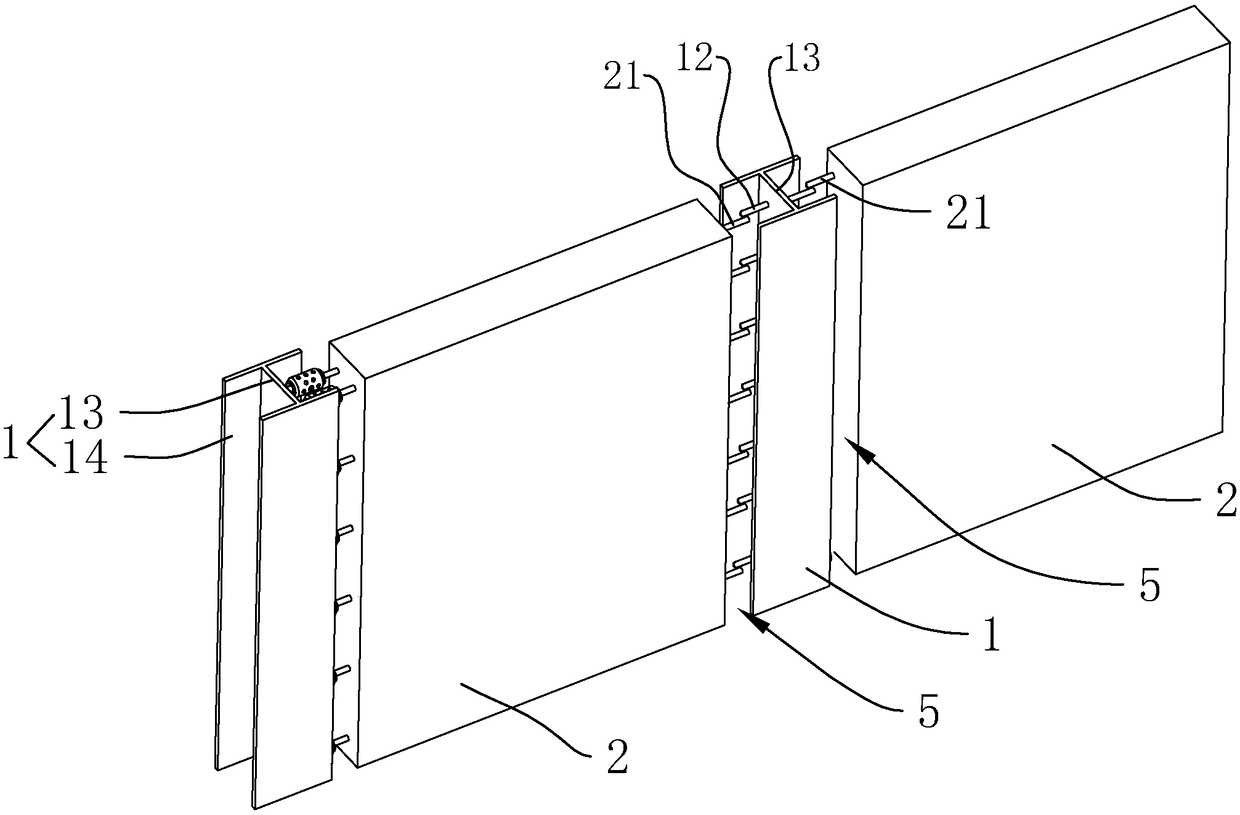

Steel frame shear wall structure

The invention provides a steel frame shear wall structure. The steel frame shear wall structure comprises a steel frame structure and a wallboard assembly, and the steel frame structure comprises supporting pillars, end beams, cross beams and beam splicing structures. The beam slicing structures comprise first end plates, second end plates and first connecting bolt components, and the wallboard assembly comprises splice bars, wallboards and second connecting bolt components. The end beams and the supporting pillars are welded and fixed to form firm beam-pillar joints, the first end plates andthe second end plates are welded, fixed and provided with first bolt holes, the splice bars are welded and fixed to the cross beams, the end beams and the supporting pillars, and all the parts are prefabricated in a factory. When the steep frame shear wall structure is installed on site, the first end plates of the cross beams and the second end plates of the end beams are matched and connected through the first connecting bolt components, accordingly a steel frame structure is installed, then the wallboards are fixedly assembled on the steel frame structure through the second bolt componentsand the splice bars, in this way, installing and operating are more convenient and easier, and construction efficiency is higher.

Owner:CHINA CONSTR STEEL STRUCTURE CORP LTD

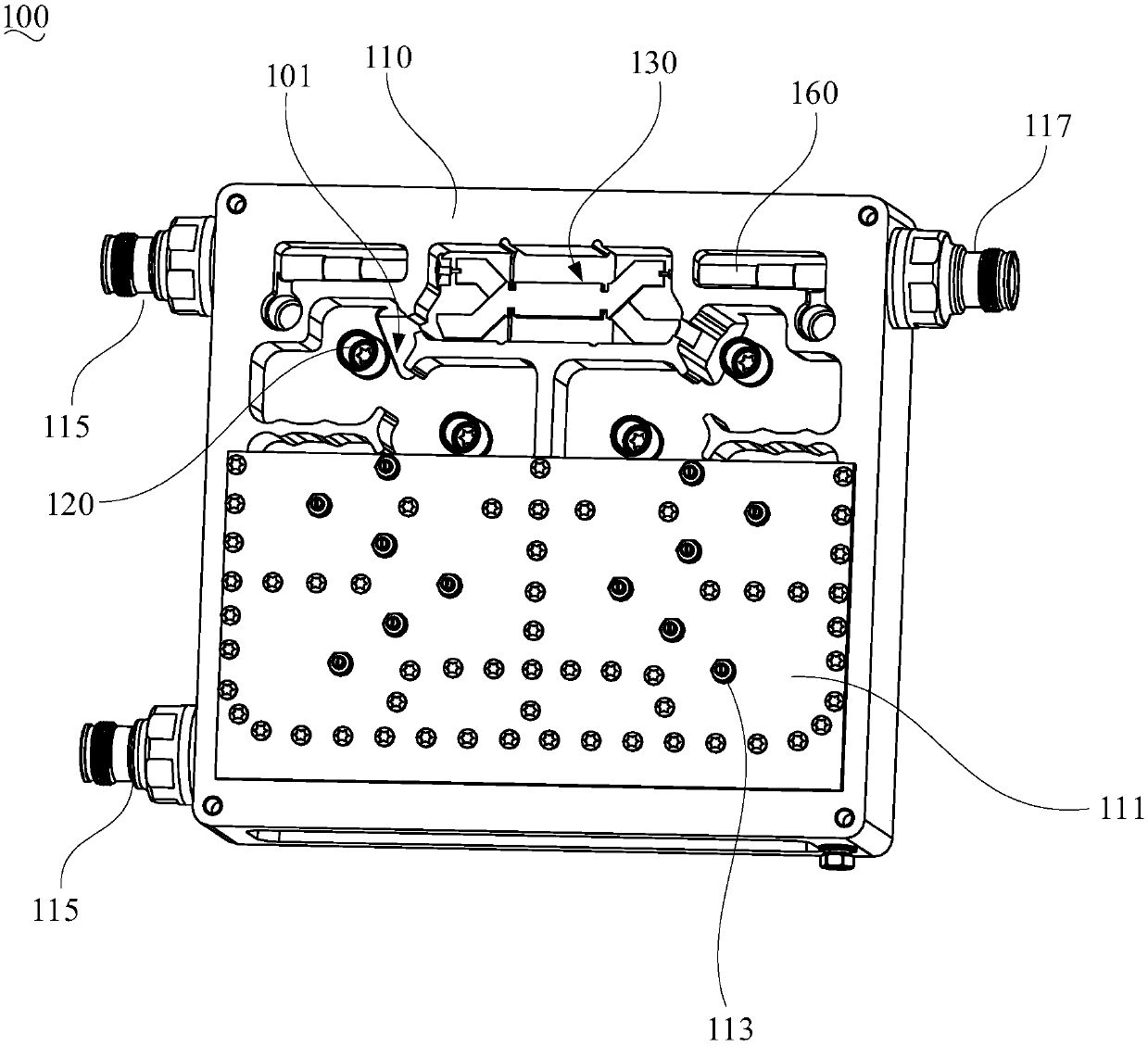

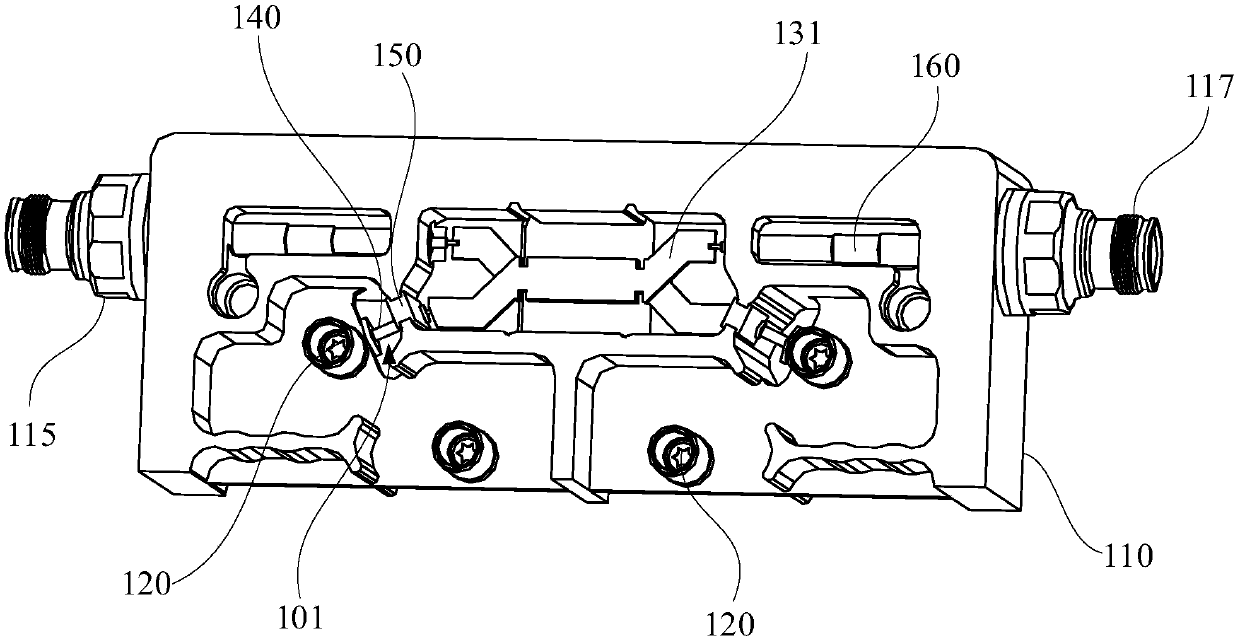

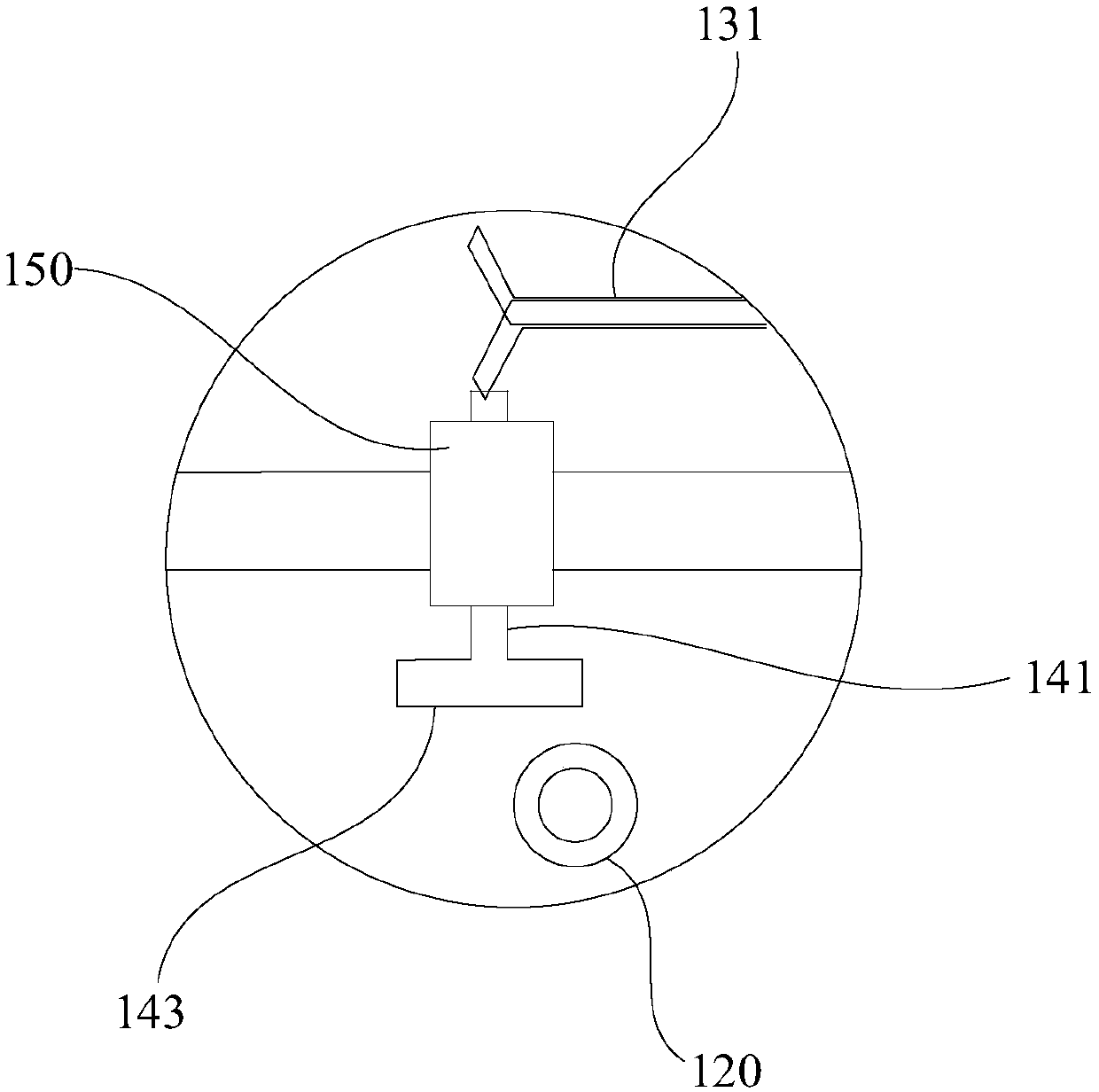

Bridge combiner

The invention relates to a bridge combiner. The bridge combiner comprises a cavity, a bridge structure, filter structures composed of a plurality of resonators, and coupling structures. The bridge structure and the filter structures are integrated in the cavity, so that the structure is compact and the volume is reduced. The resonator of the first-cavity filter structure is electrically coupled with a bridge port of a bridge conduction band sheet through the corresponding coupling structures, coupling discs are not in direct contact with the resonators, and the conduction of signals between the bridge structure and the filter structures is realized in an electric coupling manner. Compared with a traditional structure, according to the bridge combiner, the bridge structure is connected withthe filter structures without using cables or connectors, and the welding operation can be reduced obviously, so that the quantity of welding spots is reduced. Moreover, one coupling structure can realize electric coupling with the filter structures simultaneously. Therefore, the structure of the bridge combiner can be simplified effectively.

Owner:COMBA TELECOM TECH (GUANGZHOU) CO LTD +1

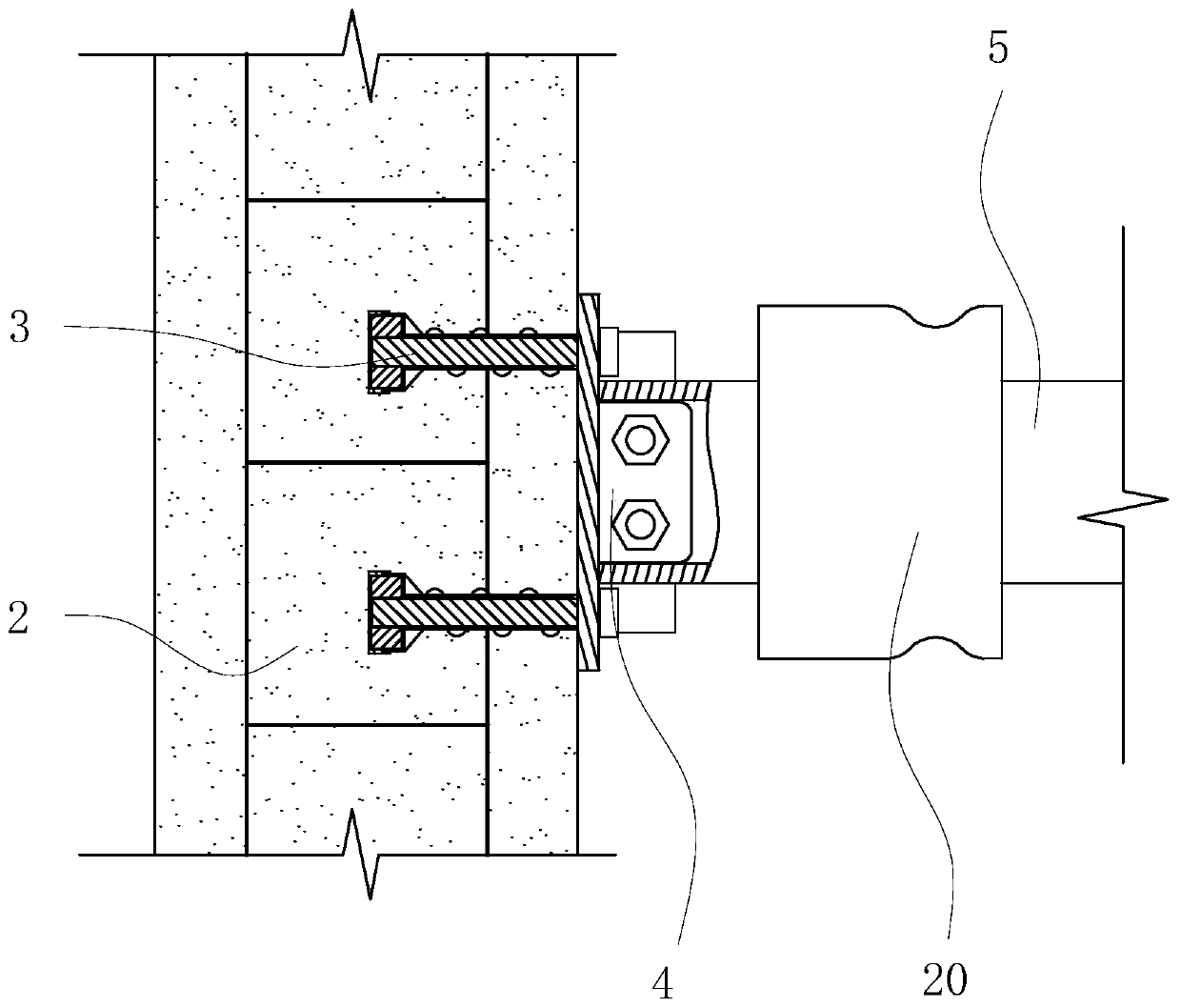

Wall connecting part structure of external scaffold and construction method of wall connecting part structure

InactiveCN111519893AReduce welding operationsImprove construction efficiencyScaffold accessoriesPipeIndustrial engineering

The invention relates to the technical field of scaffold construction, in particular to a wall connecting part structure of an external scaffold and a construction method of the wall connecting part structure. The wall connecting part structure of the external scaffold comprises embedded parts, external connecting mechanisms and connecting rods. The embedded parts, the external connecting mechanisms and the connecting rods are detachably connected through fastening bolts and fasteners, so that welding operation in the construction process of the wall connecting part structure is reduced, and construction efficiency is improved; and the wall connecting part of the external scaffold is simple in installation and disassembly construction steps and easy and convenient to disassemble and assemble, during disassembly, grout of T-shaped pipes can be completely blocked in a wall body, and the part exposed out of the side wall of the wall body does not exist, so that the problem that the wall connecting part structure remains on the outer wall of the wall body and rusts is effectively avoided, completeness of the wall body is ensured, and the wall body is not damaged.

Owner:福建省育才建设发展有限公司

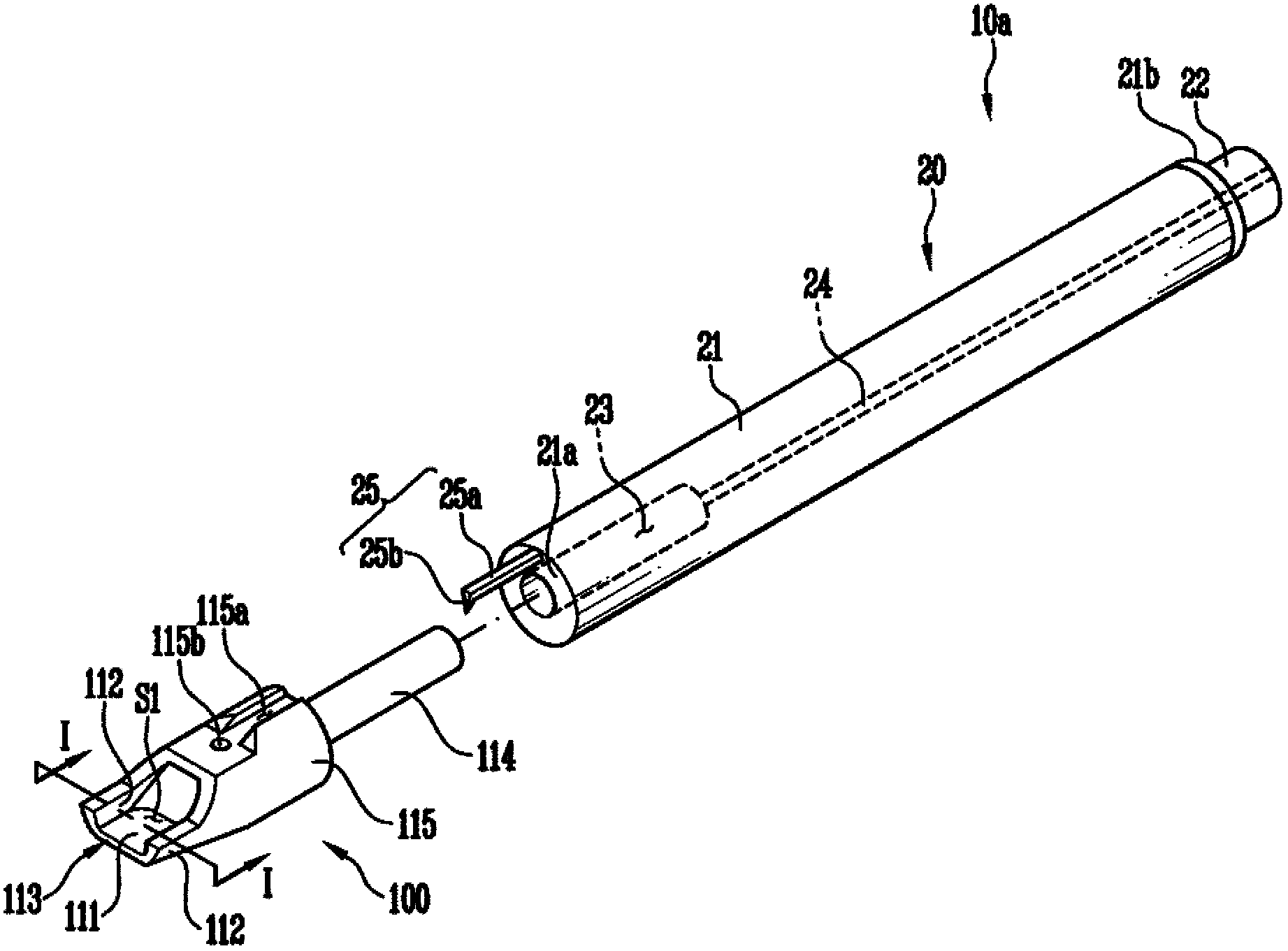

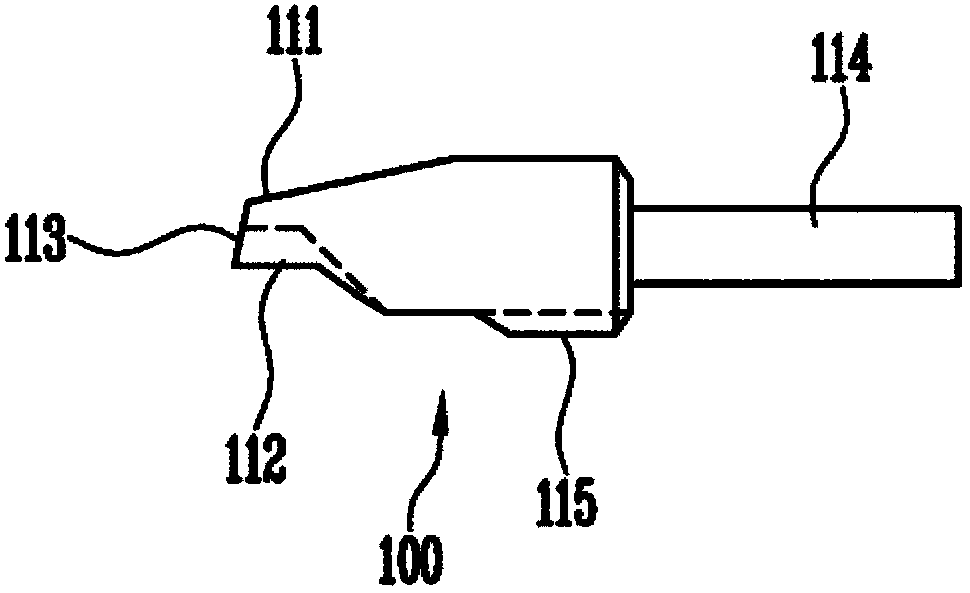

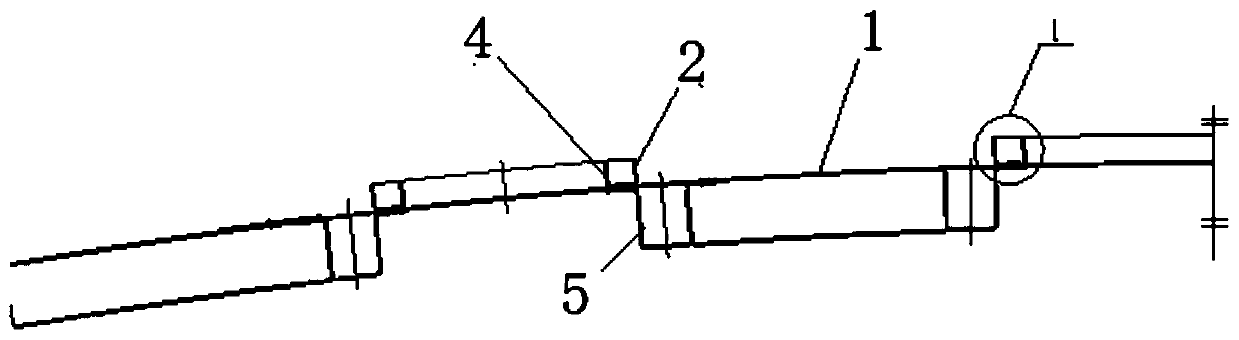

Soldering iron

InactiveCN104043887AReduce welding operationsReduce failureSoldering bitsSoldering ironEngineeringSoldering iron

Owner:SAMSUNG SDI CO LTD

Switch cabinet installation base and switch cabinet

PendingCN109713584ARealize self-locking effectEasy to operateSubstation/switching arrangement casingsSelf lockingEngineering

The invention discloses a switch cabinet installation base, which comprises a left side base body and a right side base body which are used in cooperation, wherein the left side base body and the right side base body are connected in a left-right splicing manner, a cavity is formed inside the left side base body and the right side base body, and an installation groove is formed in the upper end surfaces. Accordingly, the invention further discloses a switch cabinet, which comprises the switch cabinet installation base. The switch cabinet comprises a switch cabinet body, wherein the lower end of the switch cabinet body is arranged in the installation groove, clamping grooves are formed in the lower end of the switch cabinet body, locking blocks are clamped in the clamping grooves after installation, and the locking blocks can achieve the self-locking effect of the switch cabinet body without welding the switch cabinet body to the installation base. The operation is simple, the welding operation is omitted, the efficiency is improved, and the environment is protected; and by arranging the prefabricated installation base, the installation efficiency is further improved.

Owner:TIANJIN HUIHE ELECTRICAL EQUIP

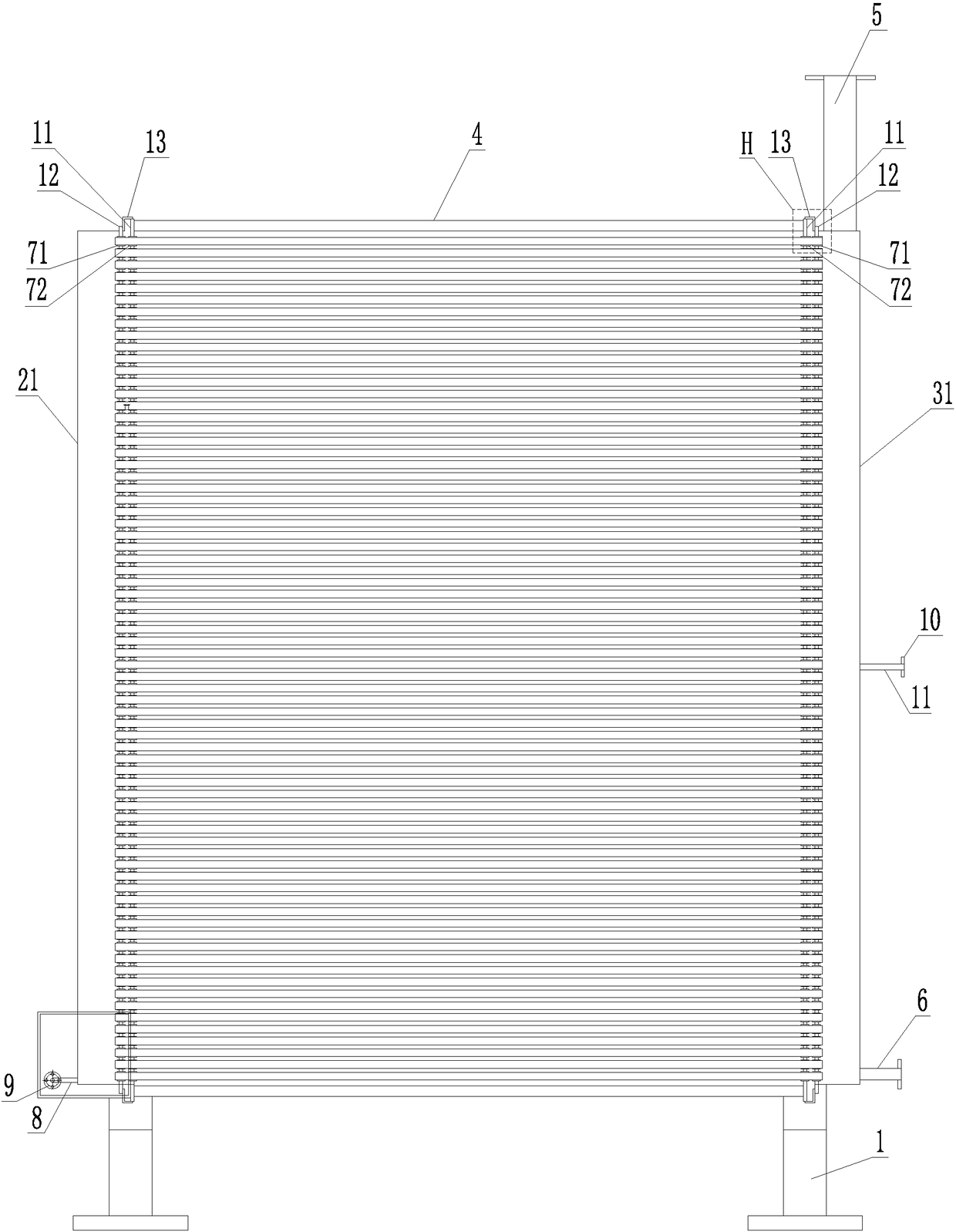

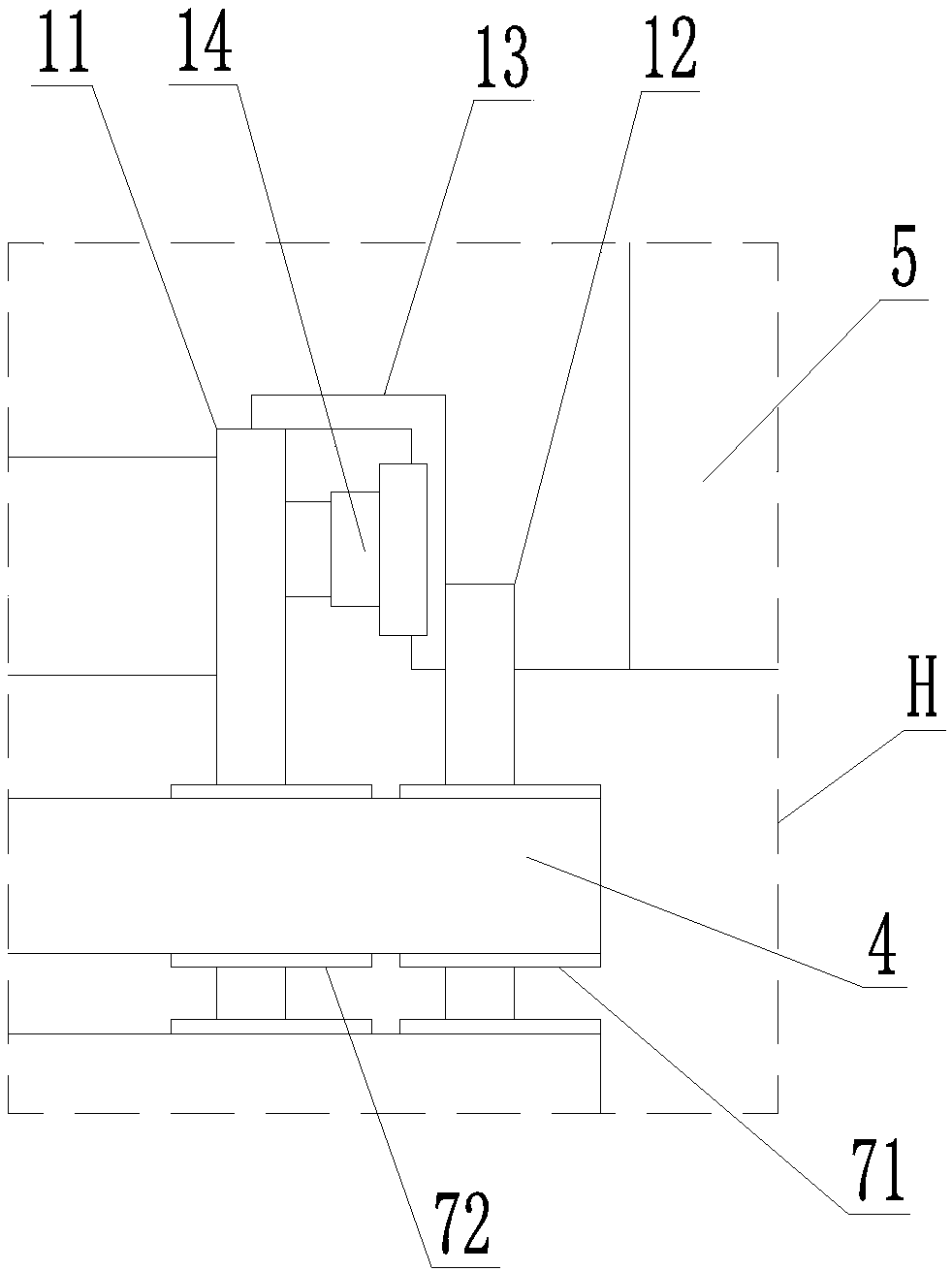

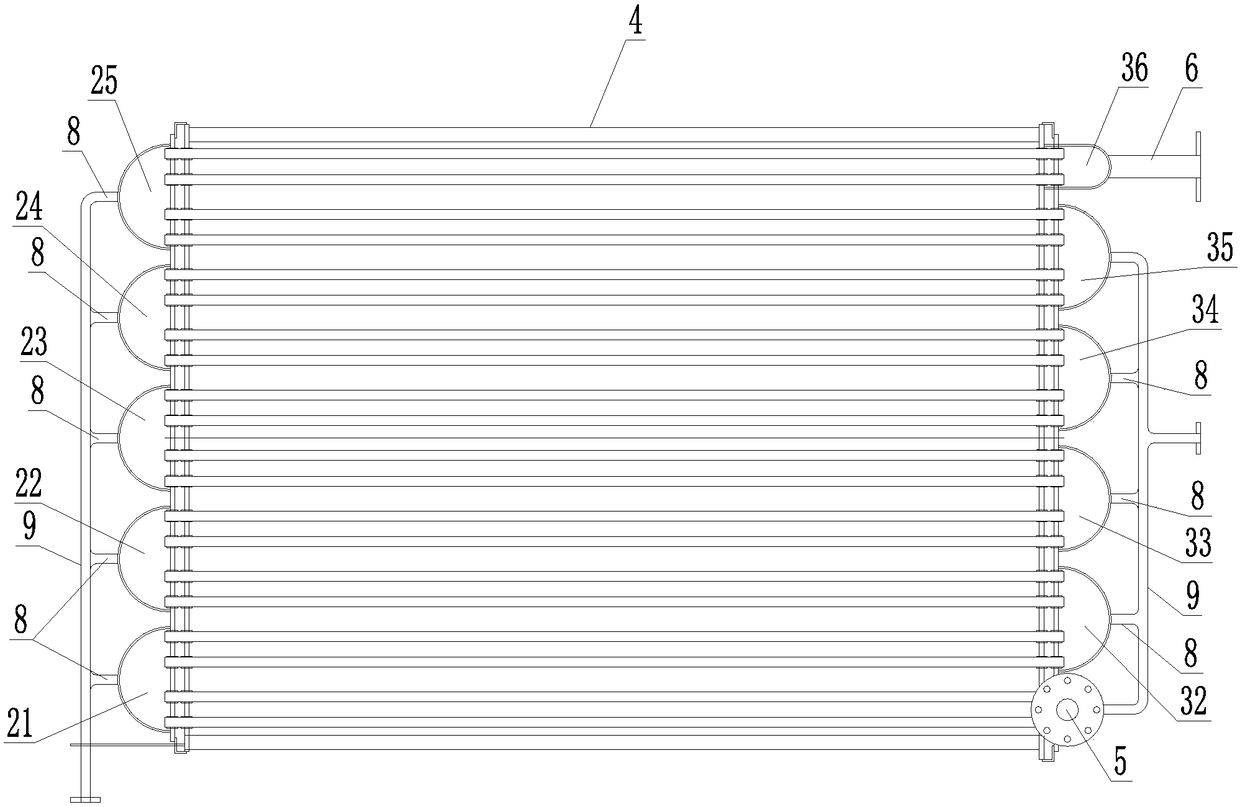

Titanium material heat exchange device

PendingCN108413785AEffective protectionAvoid wear and tearHeat exchanger casingsStationary tubular conduit assembliesTitaniumUltimate tensile strength

The invention discloses a titanium material heat exchange device. The device comprises two titanium material side plates which are distributed left and right, and a plurality of relatively independenttitanium material collecting boxes are arranged on the outer sides of the two titanium material side plates correspondingly; all the titanium material collecting boxes are connected in series througha plurality of titanium material heat exchange tubes supported between the two titanium material side plates, so that all the titanium material collecting boxes and all the titanium material heat exchange tubes form a plurality of parallel S-shaped heat exchange pipelines; a steam inlet pipe is arranged at the top of the titanium material collecting box located at the head position of the S-shaped heat exchange pipelines, and a steam outlet pipe is arranged at the bottom of the titanium material collecting box at the tail position of the S-shaped heat exchange pipelines; and a protective sleeve is arranged on the portion, in contact with each titanium material side plate, of each titanium material heat exchange tube in a sleeving mode. The titanium material heat exchange device has the advantages that the structure is compact, the situation that the titanium material heat exchange tubes are damaged due to friction between the titanium material heat exchange tubes and the titanium material side plate in the using process can be avoided, and the service life of the heat exchange tubes is long; and the overall structure is high in stability and strength, the assembling efficiency ishigh, and the use safety is high.

Owner:江苏龙净节能科技有限公司

Stacked package with ground ring and method of processing the same

ActiveCN112151510BSave spaceImprove securitySemiconductor/solid-state device detailsSolid-state devicesElectric machineGear wheel

The invention discloses a stacking package with a grounding ring and a processing method thereof. A hinged ferrule, a connecting plate, a grounding ring, a second receiving slot and a rotating shaft, an inner wall of one side of the main body of the package is provided with a mounting slot, and a motor is distributed and mounted on the inner wall of the bottom end of the mounting slot. Gears are installed on the inner wall of one side of the installation slot, and one end of the output shaft of the motor is fixed to the inside of the gear. The outer wall of one side of the gear is meshed and connected with a rack. The invention adopts the method of grounding ring to reduce ground The connection of the wire facilitates the installation and fixation of the chip, reduces the space of the package, and facilitates the installation of the grounding ring, reduces the welding operation, avoids the generation of a large amount of harmful gas during welding, prevents environmental pollution, and improves the safety of the package.

Owner:ANHUI LONGXINWEI TECH CO LTD

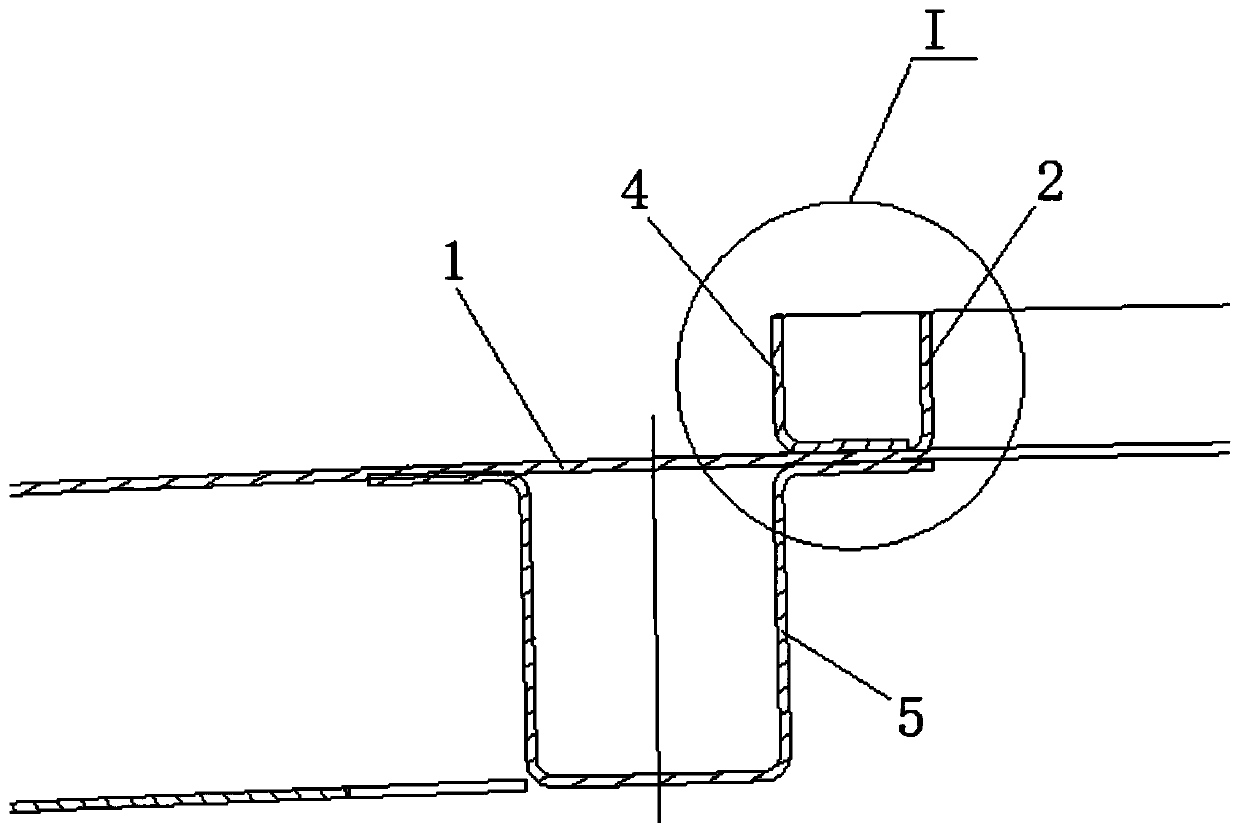

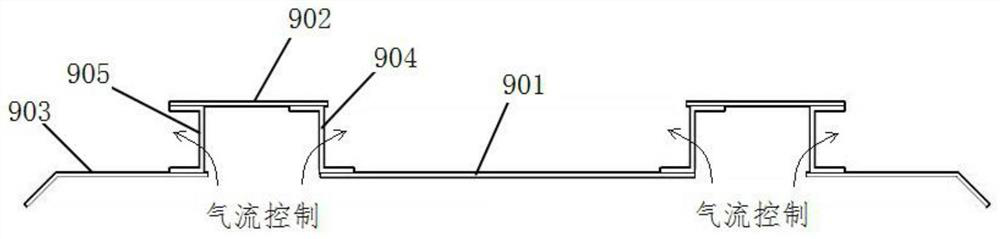

Train roof frame, train air conditioning installation structure and train

ActiveCN110027579BSave spaceSolving Seal Installation ProblemsRailway roofsRailway heating/coolingControl theoryCarriage

The invention relates to the technical field of train air conditioner installation, in particular to a train top holder, a train air conditioner installation structure and a train. The train top holder comprises a train top plate, enclosing plates and supporting parts, wherein a plurality of through holes are formed in the train top plate, and flangings around the through holes are arranged on thepositions, at the edges of the through holes, of the train top plate; the enclosing plates are installed on the upper surface, away from a passenger room, of the train top plate, and arranged relative to the flangings, and the enclosing plates and the flangings are enclosed to form U-shaped grooves; the U-shaped grooves are formed around the edges of the through holes; and the supporting parts are installed on the lower surface, close to the passenger room, of the train top plate. The through holes are formed in the train top plate of the train top holder, the flangings are arranged at the edges of the through holes, and the flangings and the enclosing plates are enclosed to form the U-shaped grooves. During installation of an air conditioner, sealing joint strips can be installed in theU-shaped grooves, thus the sealing installation problem is solved. During installation of the air conditioner, the air conditioner is directly installed on the train top plate, sinking installation isnot required, and the space in a carriage is saved.

Owner:CRRC QINGDAO SIFANG CO LTD

Train top holder, train air conditioner installation structure and train

ActiveCN110027579ASave spaceSolving Seal Installation ProblemsRailway roofsRailway heating/coolingEngineeringFlanging

The invention relates to the technical field of train air conditioner installation, in particular to a train top holder, a train air conditioner installation structure and a train. The train top holder comprises a train top plate, enclosing plates and supporting parts, wherein a plurality of through holes are formed in the train top plate, and flangings around the through holes are arranged on thepositions, at the edges of the through holes, of the train top plate; the enclosing plates are installed on the upper surface, away from a passenger room, of the train top plate, and arranged relative to the flangings, and the enclosing plates and the flangings are enclosed to form U-shaped grooves; the U-shaped grooves are formed around the edges of the through holes; and the supporting parts are installed on the lower surface, close to the passenger room, of the train top plate. The through holes are formed in the train top plate of the train top holder, the flangings are arranged at the edges of the through holes, and the flangings and the enclosing plates are enclosed to form the U-shaped grooves. During installation of an air conditioner, sealing joint strips can be installed in theU-shaped grooves, thus the sealing installation problem is solved. During installation of the air conditioner, the air conditioner is directly installed on the train top plate, sinking installation isnot required, and the space in a carriage is saved.

Owner:CRRC QINGDAO SIFANG CO LTD

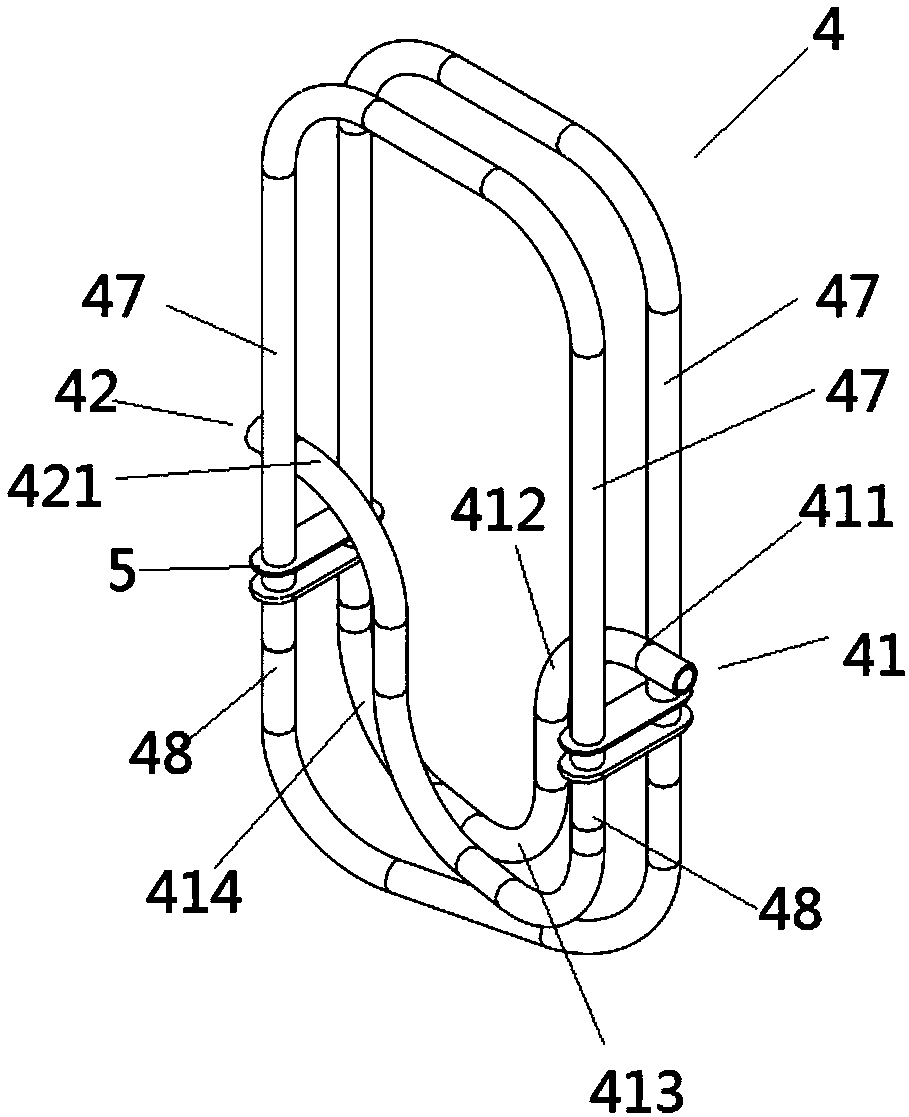

Coriolis mass flowmeter and sensor assembly thereof

PendingCN109425397AReduce vibration couplingImprove the vibration stateVolume meteringDirect mass flowmetersEngineeringVibration isolation

The invention discloses a Coriolis mass flowmeter and a sensor assembly thereof. The flowmeter includes an upstream pipeline connector used for being connected to an upstream fluid pipeline and a downstream pipeline connector used for being connected with a downstream fluid pipeline. The sensor assembly is installed in a shell of the flowmeter and comprises a fluid flow pipe, a vibration isolationstructure, a weight addition structure and a connection structure; the fluid flow pipe is provided with a fluid input pipeline, a fluid output pipeline and a double loop pipeline connected between the input pipeline and the output pipeline in series; the vibration isolation structure at least includes a first vibration isolation piece which is fixedly arranged on the fluid flow pipe and divides the fluid flow pipe into a vibration pipeline and a non-vibration pipeline; the weight addition structure is arranged on the non-vibration pipeline, and the weight addition structure and the non-vibration pipeline are not in contact with the shell. One end of the connection structure is fixedly connected to the non-vibration pipeline, and the other end of the connection structure is fixedly connected to the upstream pipeline connector and / or the downstream pipeline connector to enable the non-vibration pipeline to be flexibly connected with the upstream pipeline connector and / or the downstreampipeline connector correspondingly.

Owner:罗凡

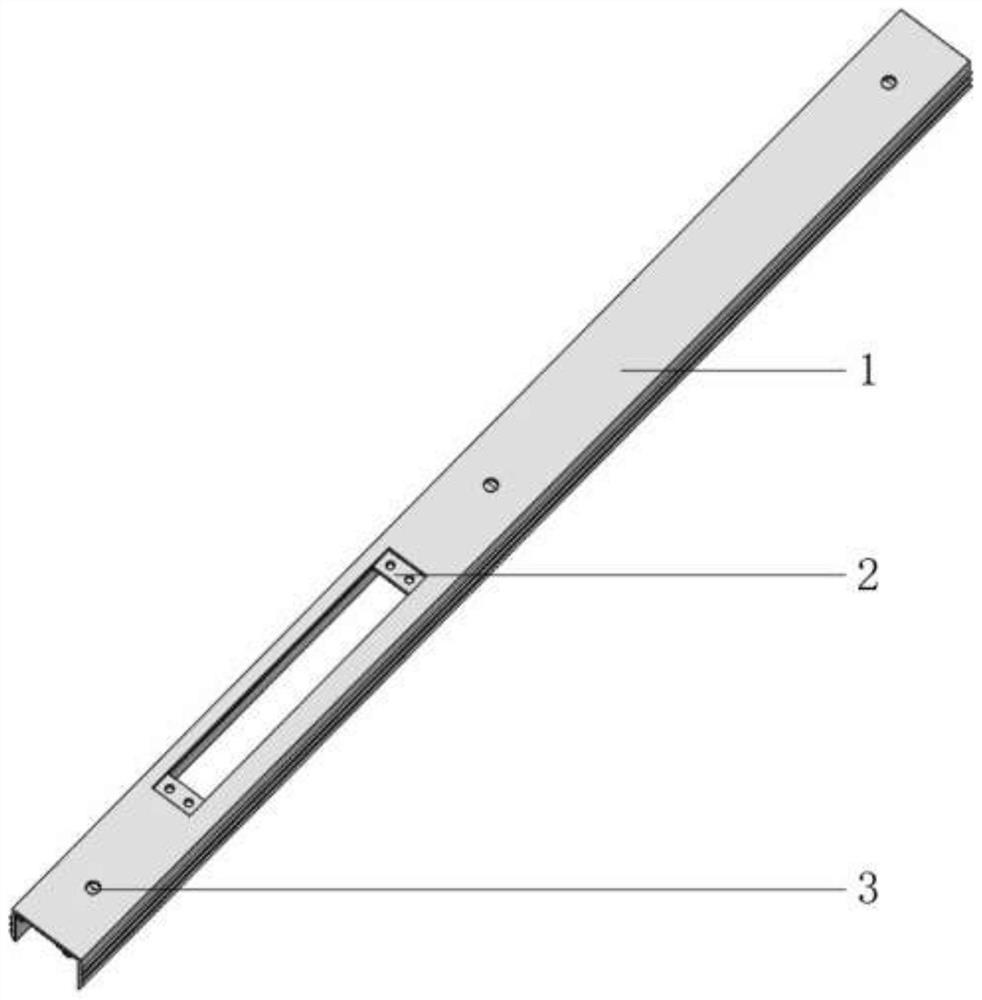

Connecting structure and method for integrated profile steel and cross beam

The invention discloses a connecting structure and method for integrated profile steel and a cross beam. The connecting structure comprises a connector arranged on the integrated profile steel, a tenon arranged at the end of the cross beam and brake iron, the edge of the end of the tenon exceeds the side wall of the tenon to form a limiting edge, a mounting cavity is formed in the connector, two wedge-shaped blocks are arranged on the two sides of the mounting cavity, the two wedge-shaped blocks are arranged in a spaced mode and form an installation seam gradually narrowing from top to bottom,the tenon is placed into the installation cavity from top to bottom, the limiting edge is embedded into the installation seam, and the brake iron is inserted into a gap between the limiting edge andthe installation seam to fasten the limiting edge. The connecting structure of the integrated structural steel and the cross beam replaces an original connecting mode combined bolt connection and welding, rapid and reliable on-site installation is achieved through splicing and clamping, the connecting gap is reduced, welding operation is omitted, the connecting strength is guaranteed, the on-siteassembly difficulty is lowered, and a new thought is provided for the installation mode of the cross beam. The invention further discloses a connecting method of the integrated profile steel and the cross beam.

Owner:WUXI GUANGCAI MACHINERY MFG

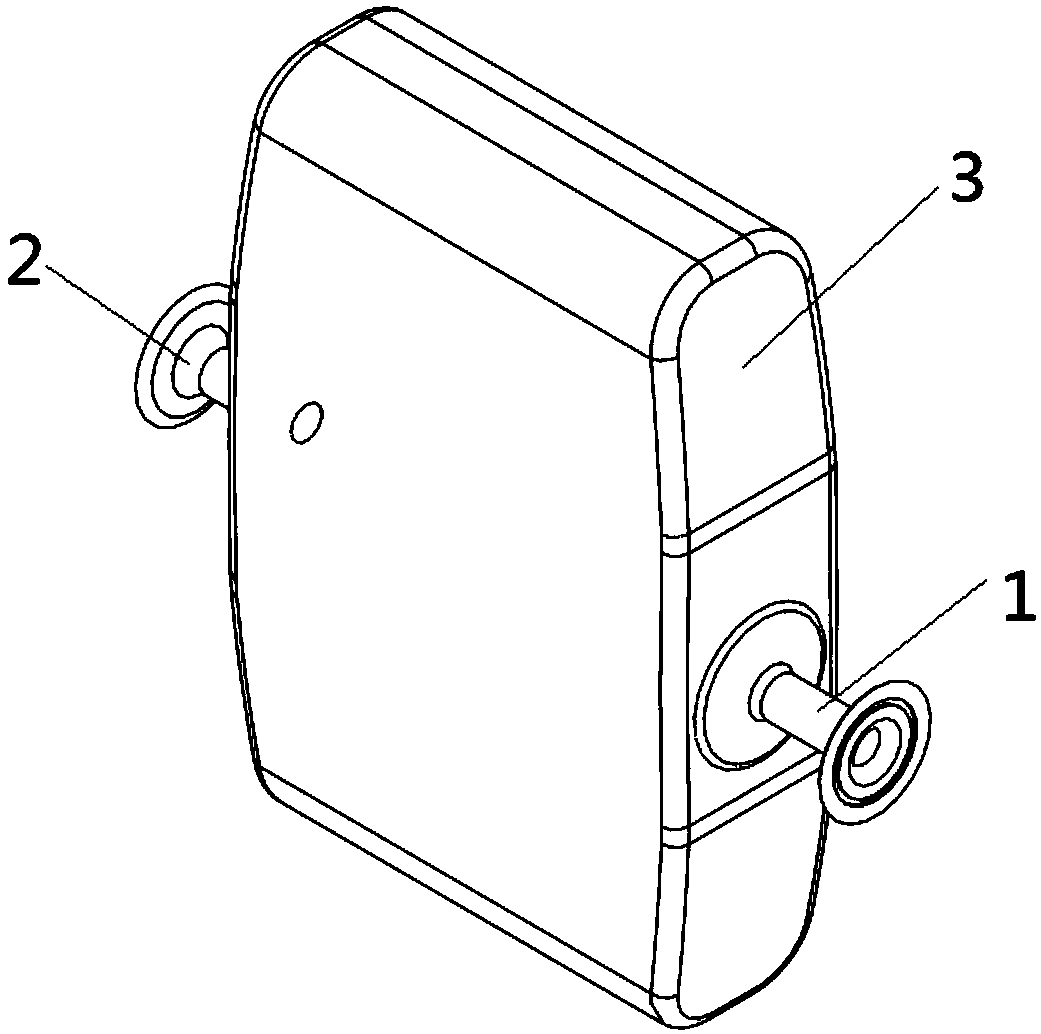

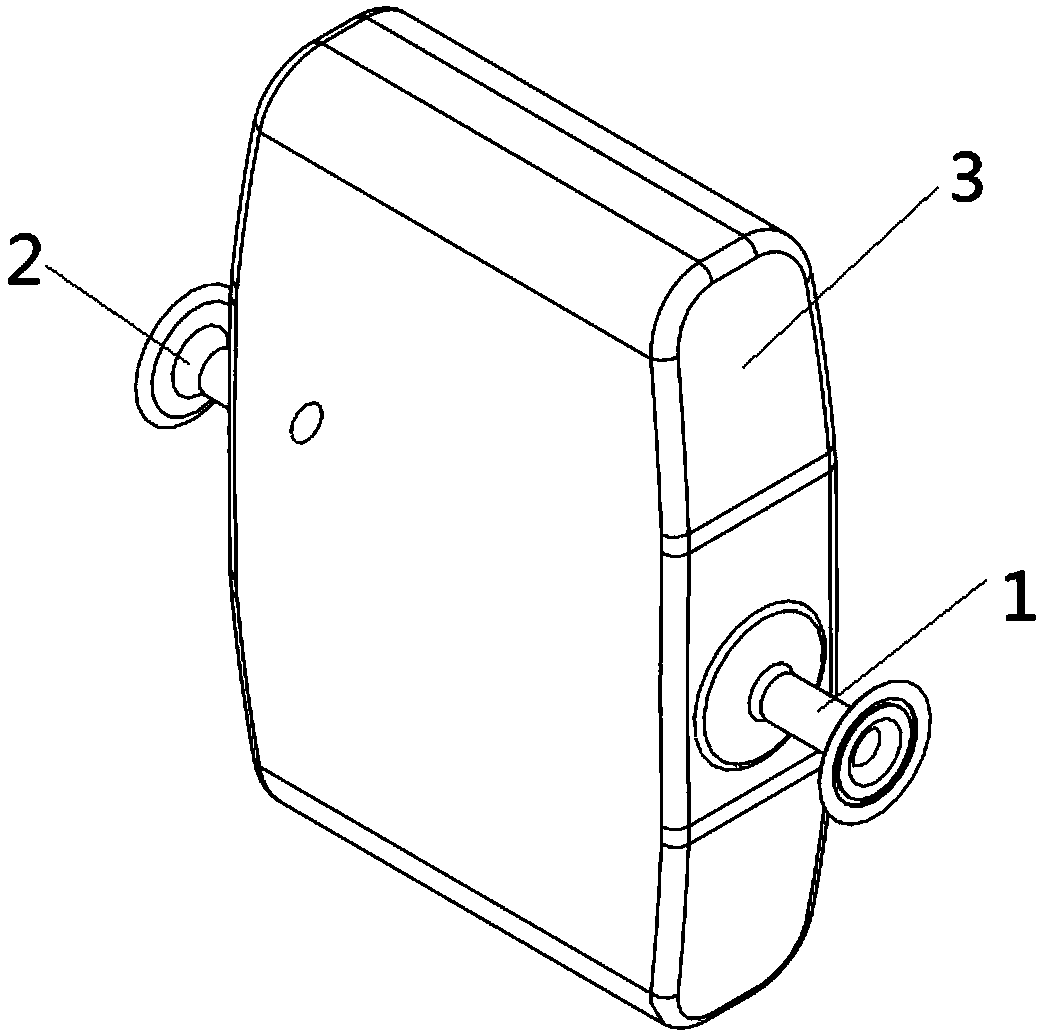

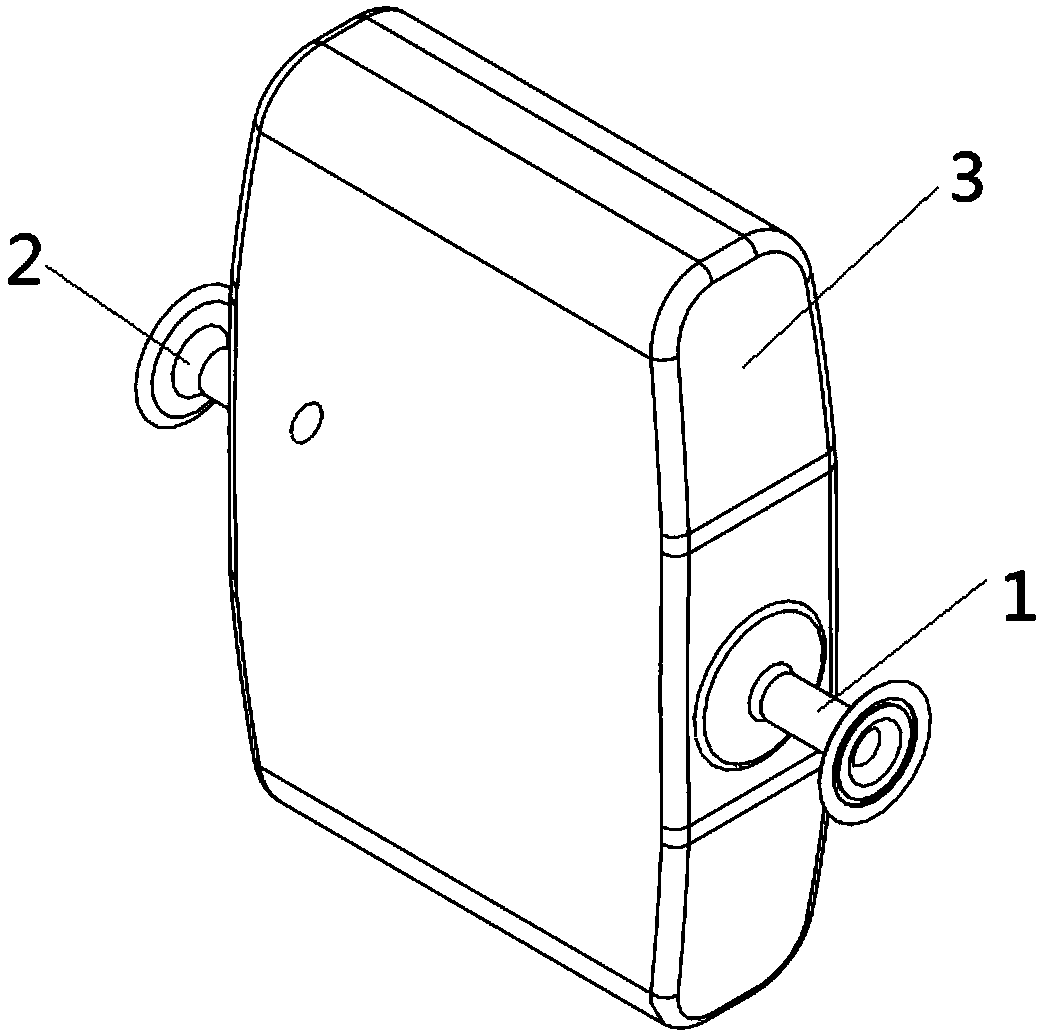

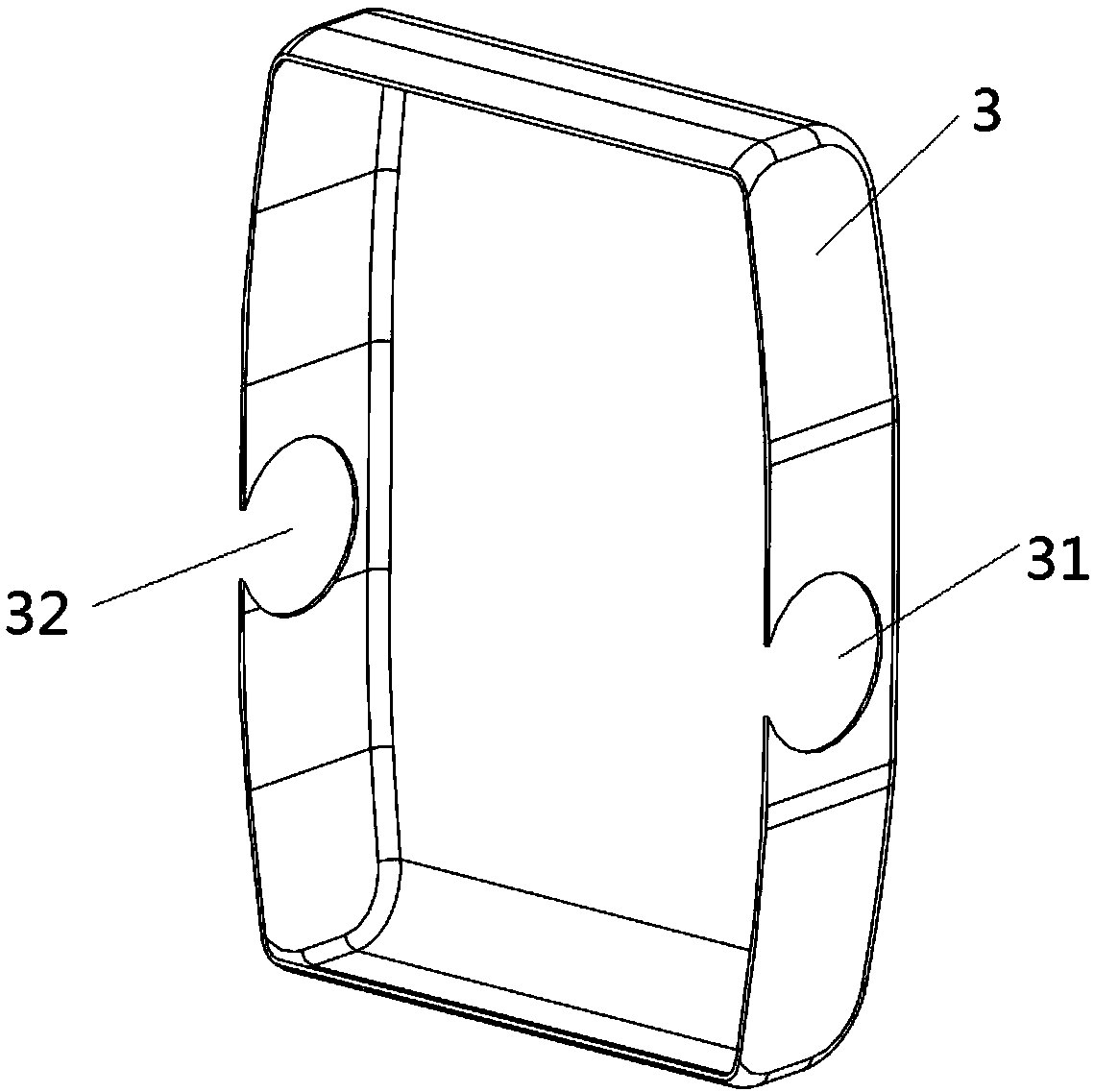

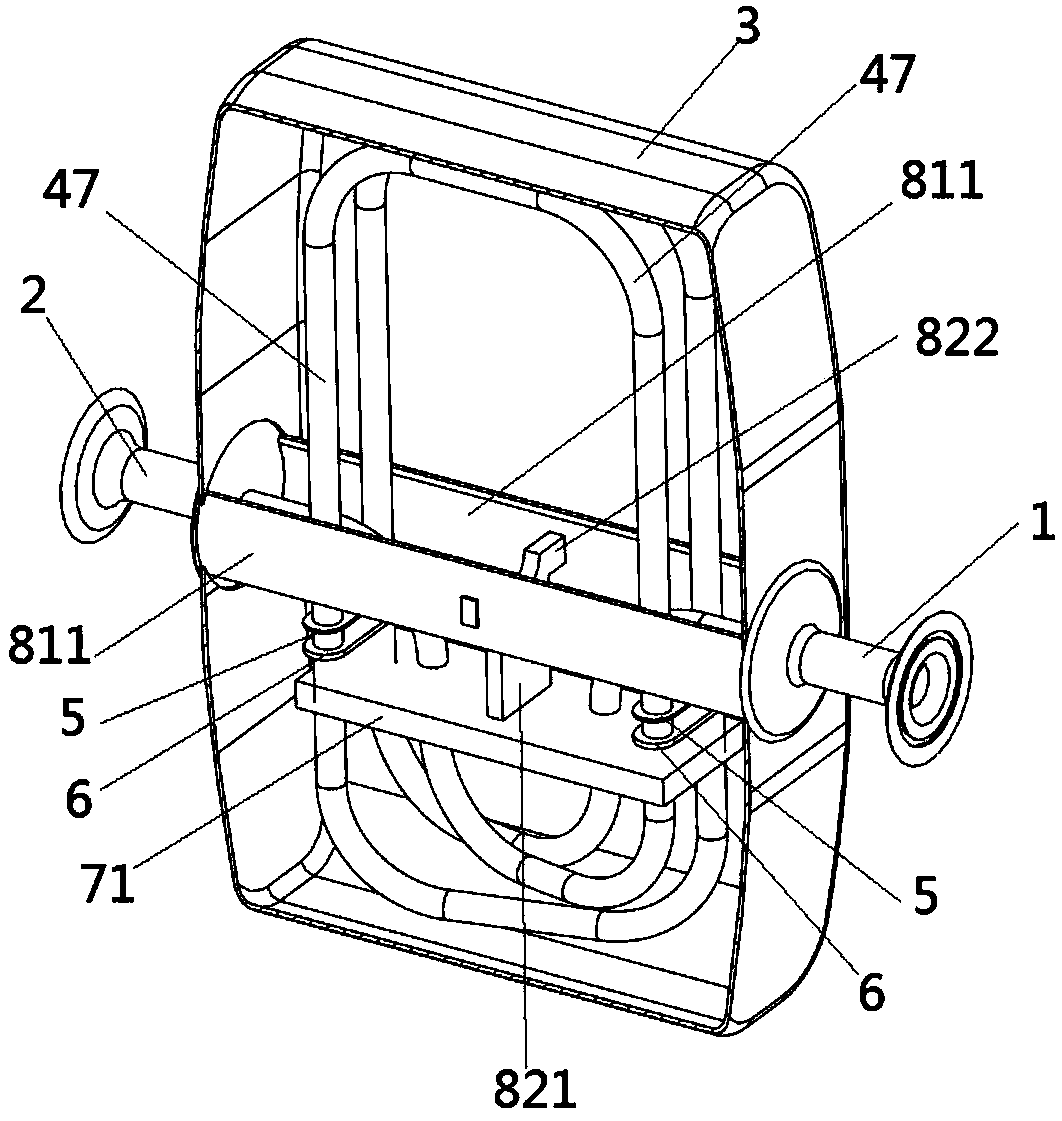

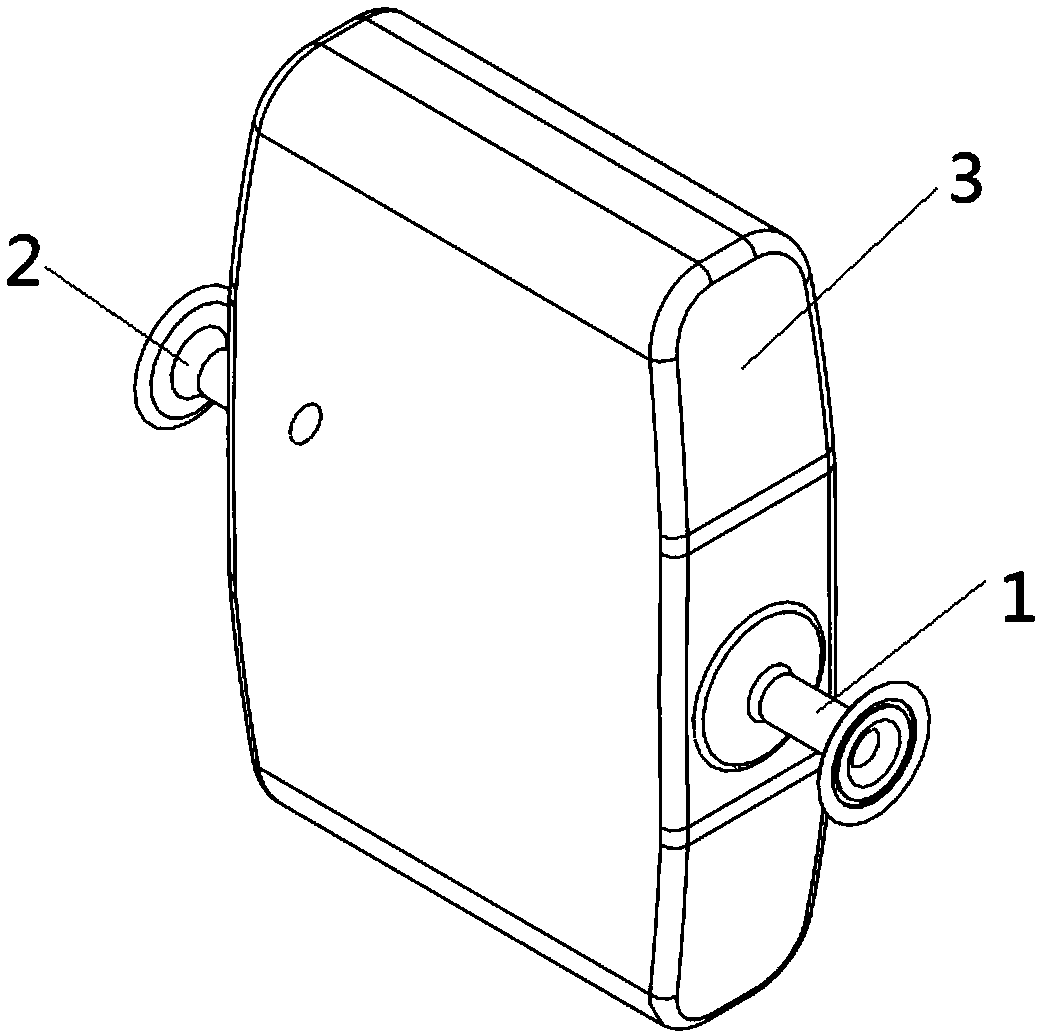

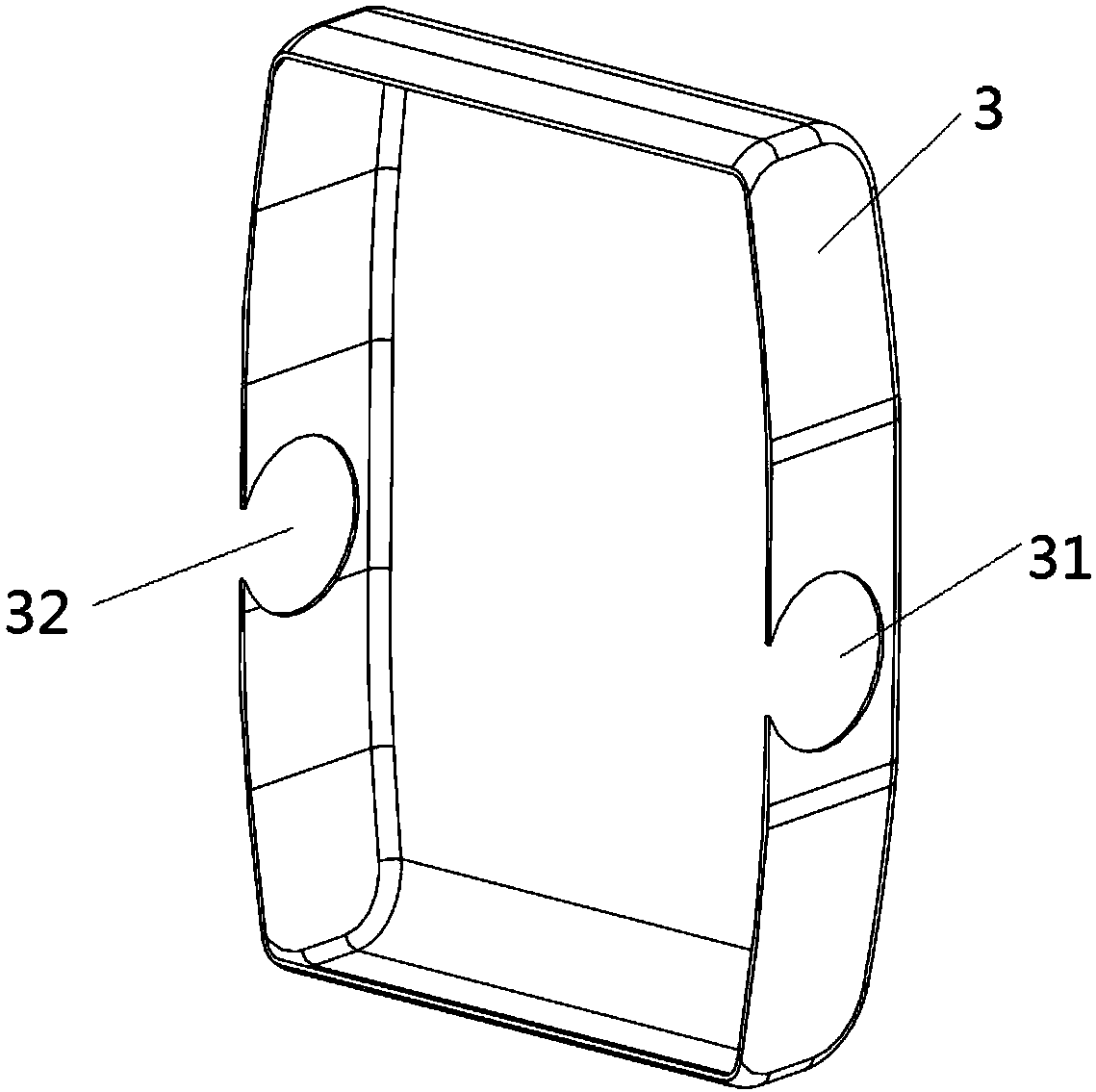

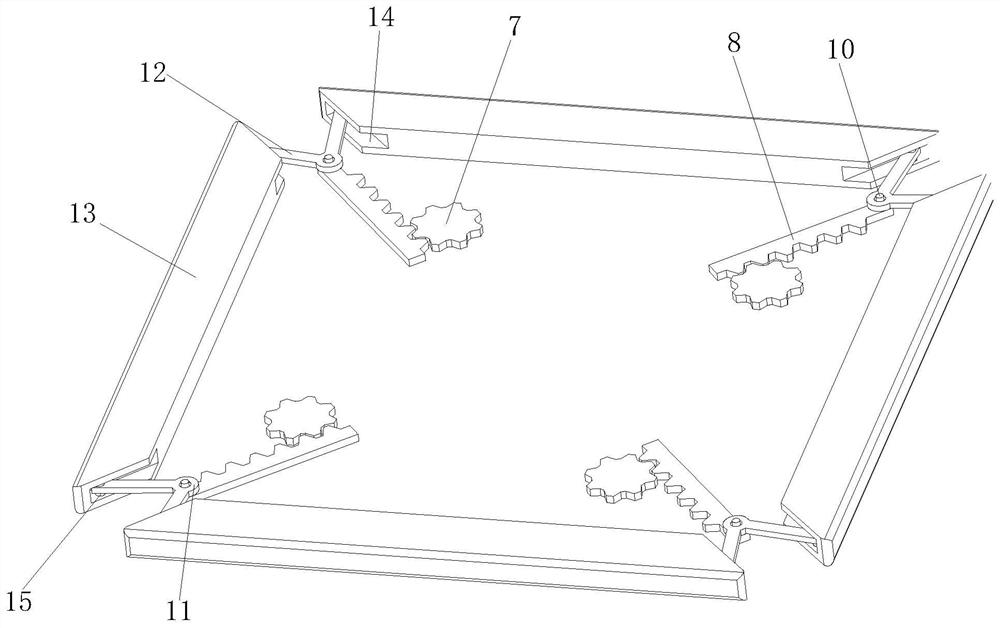

Door closer inner framework of hidden entrance door

The invention provides a hidden door closer inner skeleton of an entrance door, the hidden door closer inner skeleton comprises an inner skeleton steel frame, a reinforcing mechanism is arranged at one end in the inner skeleton steel frame, and a plurality of tensioning mechanisms are arranged on the lower portion of the inner skeleton steel frame, according to the hidden door closer inner skeleton, the embedding friction force of the inner skeleton steel frame in a door body is enhanced through anti-skid teeth on the two sides of the inner skeleton steel frame, and embedding is more stable; the reinforcing plate is installed through the reinforcing mechanism in an inserted mode, welding operation is omitted, the problems caused by welding are avoided, the structure is simple, the size of the reinforcing plate can be adjusted, the width of the inner skeleton steel frame is adjusted through the multiple tensioning mechanisms, and therefore the inner skeleton steel frame can adapt to grooving width errors caused by inaccuracy during grooving.

Owner:安徽曼特安防科技有限公司

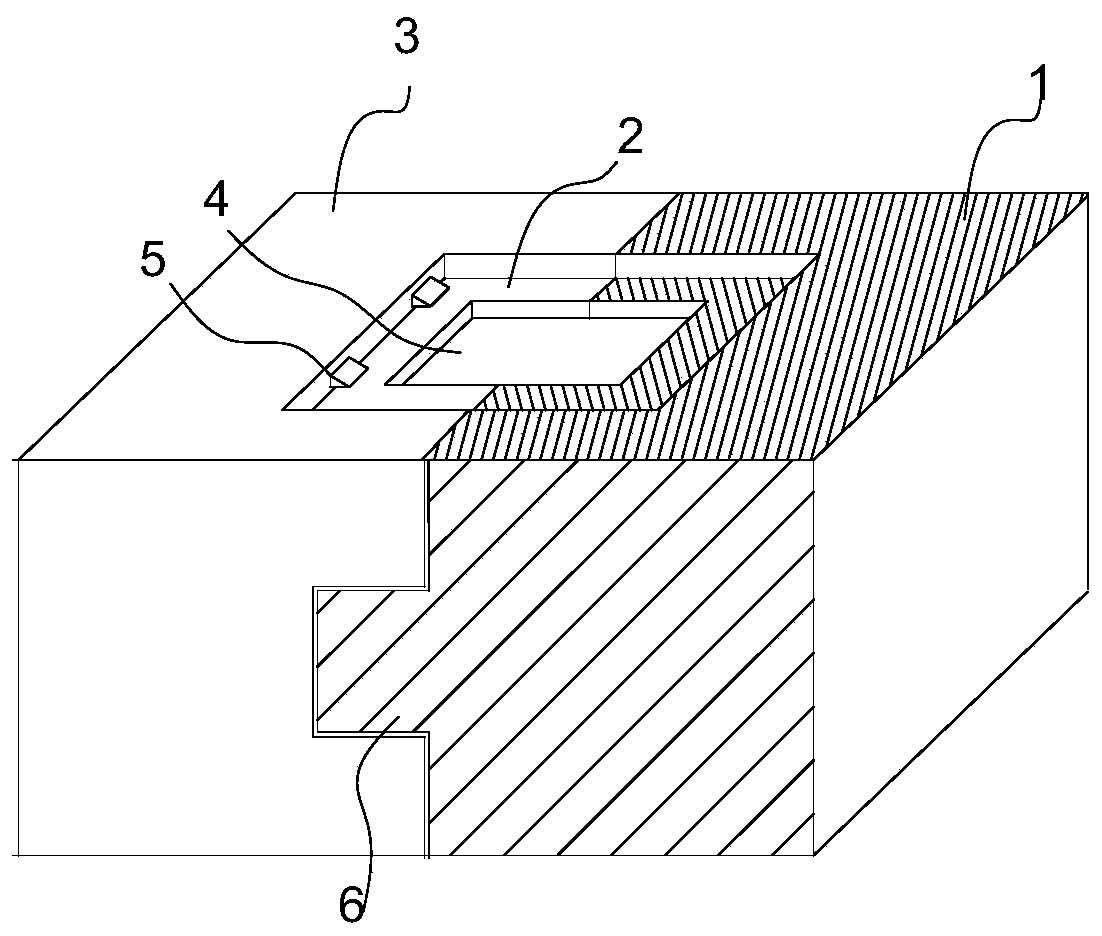

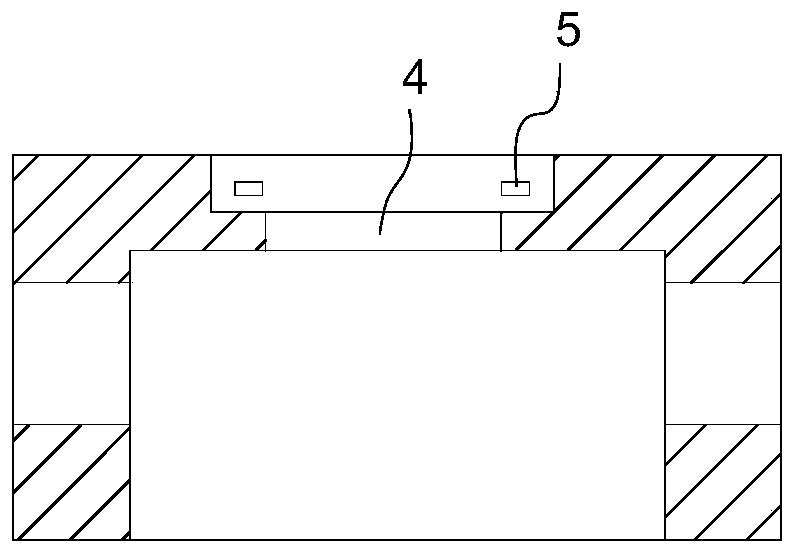

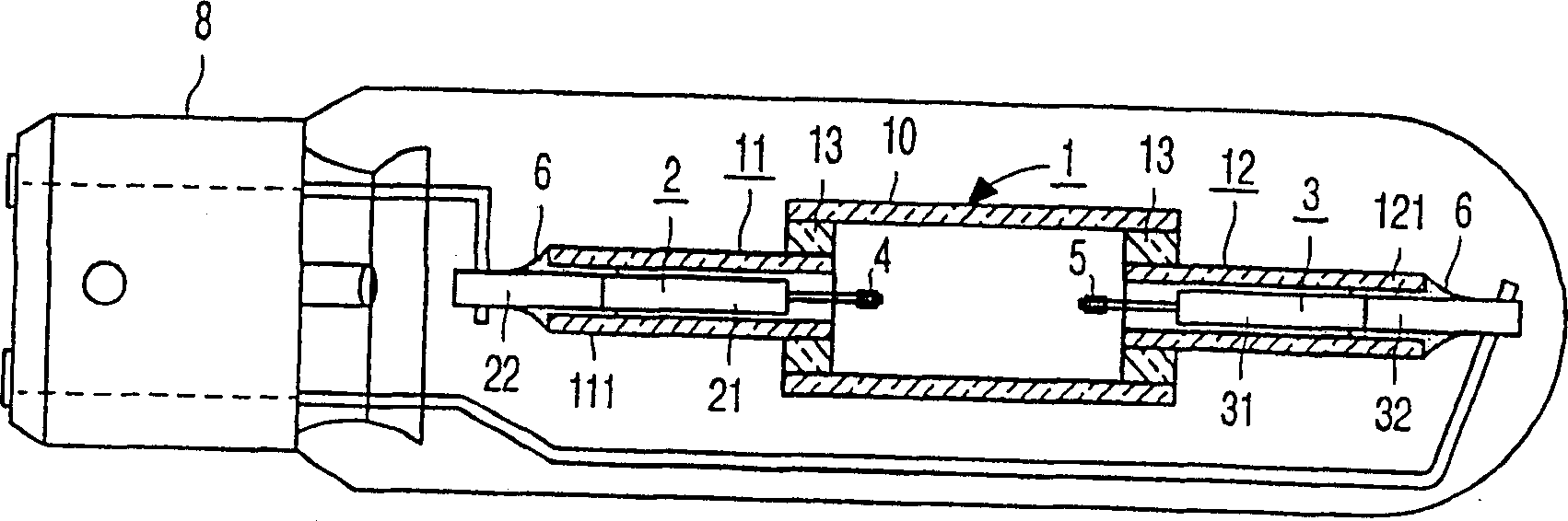

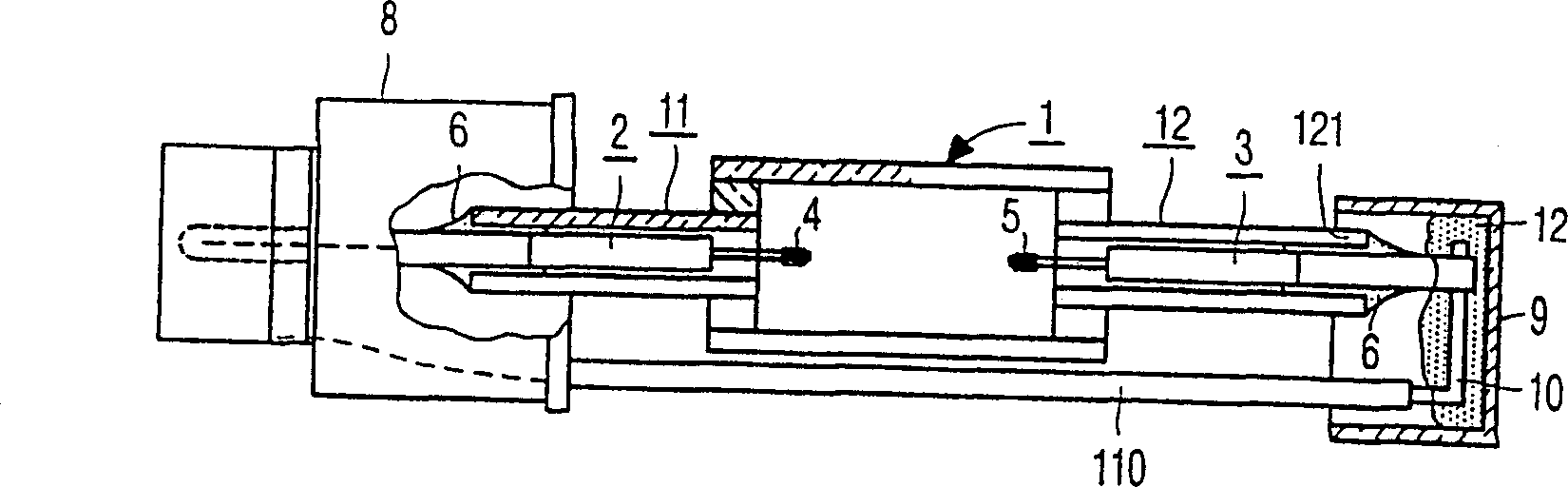

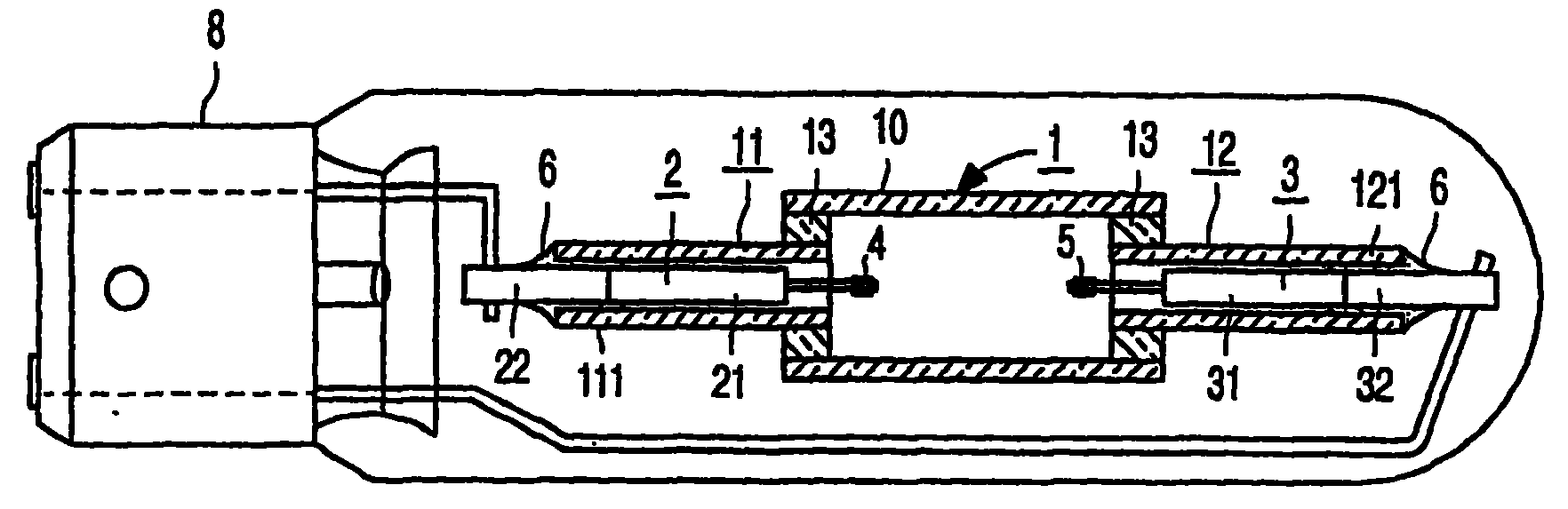

Electric lamp

InactiveCN1298015CSimplify the manufacturing processAvoid erosionGas discharge lamp detailsElectrical conductorThermal expansion

The electric lamp has a ceramic lamp vessel (1) having a filling of rare gas and metal halide. Current conductors (2, 3) which support electrodes (4, 5) inside the discharge vessel (1) enter the discharge vessel (1) in a gastight manner through a ceramic sealing compound (6). At least one of the current conductors (2, 3) has inside the lamp vessel (1) a first, halogen-resistant part (21, 31) which is selected from tungsten silicide, molybdenum aluminide, molybdenum boride, pentamolybdenum trisilicide and combinations of at least two of these intermetallic compounds. These compounds have a coefficient of thermal expansion which corresponds to that of the discharge vessel (1). It is thereby prevented that the discharge vessel starts leaking if the ceramic sealing compound (6) extends beyond the first part (21, 31). As a result of their coefficient of thermal expansion, the intermetallic compounds may constitute the second part (22, 32) of the current conductors (2, 3) as well, which part (22, 32) is surrounded by the ceramic sealing compound (6) in a gastight manner.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Coriolis mass flowmeter and sensor assembly thereof

PendingCN109425396AReduce vibration couplingImprove linearityVolume meteringDirect mass flowmetersEngineeringVibration isolation

The invention discloses a Coriolis mass flowmeter and a sensor assembly thereof. The sensor assembly comprises a fluid flow pipe, a vibration isolation structure and a weight addition structure; the fluid flow pipe is provided with a fluid input pipeline, a fluid output pipeline and a double loop pipeline connected between the input pipeline and the output pipeline in series; the vibration isolation structure is arranged on the double loop pipeline to divide the double loop pipeline into a vibration pipeline and a non-vibration pipeline; the weight addition structure is arranged on the non-vibration pipeline, and the weight addition structure and the non-vibration pipeline are not in contact with a shell. According to the Coriolis mass flowmeter and the sensor assembly thereof, the gravitycenter of the sensor assembly is adjusted by arranging the weight addition structure on the non-vibration pipeline, so that the vibration state is improved, and the vibration coupling between the non-vibration pipeline and the vibration pipeline is reduced. Moreover, the weight addition structure and the non-vibration pipeline are not in contact with the flowmeter shell, so that a non-vibration part of the sensor assembly is not rigidly connected with the flowmeter shell, the vibration isolation effect is improved, and the flowmeter obtains a stable zero point and achieves excellent meteringperformance conveniently.

Owner:罗凡

Built-in structure of motor grounding terminal

PendingCN113691082AGuaranteed operational safetyPrevent external electromagnetic interferenceAssociation with grounding devicesSupports/enclosures/casingsElectric machineBrush

The invention relates to the technical field of motors, in particular to a built-in structure of a motor grounding terminal, which comprises a casing and a brush holder connected with the casing. A first terminal and a second terminal are respectively arranged on two sides of the brush holder. A grounding terminal is arranged on the side, close to the first terminal, of the brush holder. One end of the grounding terminal abuts against the first terminal, and the other end of the grounding terminal abuts against the casing. An end cover is arranged at the end, close to the brush holder, of the casing. The built-in grounding terminal mode is adopted, traditional welding operation can be omitted, the grounding terminal is in stable and reliable contact with the casing and the terminals, loosening and falling are not prone to occurring, the operation is convenient, and the appearance is simple and attractive.

Owner:东莞维奥电机科技有限公司

A lead frame of a high-power drive circuit and its production method

ActiveCN112216668BAvoid it happening againProtect healthSemiconductor/solid-state device detailsSolid-state devicesEngineeringLead frame

The invention discloses a lead frame of a high-power driving circuit and a production method, comprising a lead frame body, a splicing component is fixed inside one side of the lead frame body, and a heat dissipation component is fixed outside one side of the lead frame body; The splicing assembly includes engaging blocks that are distributed and welded on one side of the lead frame main body, one side of the lead frame main body is provided with engaging grooves corresponding to the engaging blocks, and one side of the lead frame main body is provided with engaging grooves. A moving groove, a connecting plate is installed inside one side of the moving groove, the invention can quickly perform the splicing operation, so that a plurality of lead frame bodies can be fixedly connected, which can also reduce the welding operation and avoid the generation of a lot of harmful gases during the welding process. , can effectively protect the environment, also protect personal health, reduce safety hazards, and can continue to conduct heat and heat dissipation, so that the heat inside the main body of the lead frame is rapidly dissipated, and the heat dissipation efficiency is improved.

Owner:ANHUI LONGXINWEI TECH CO LTD

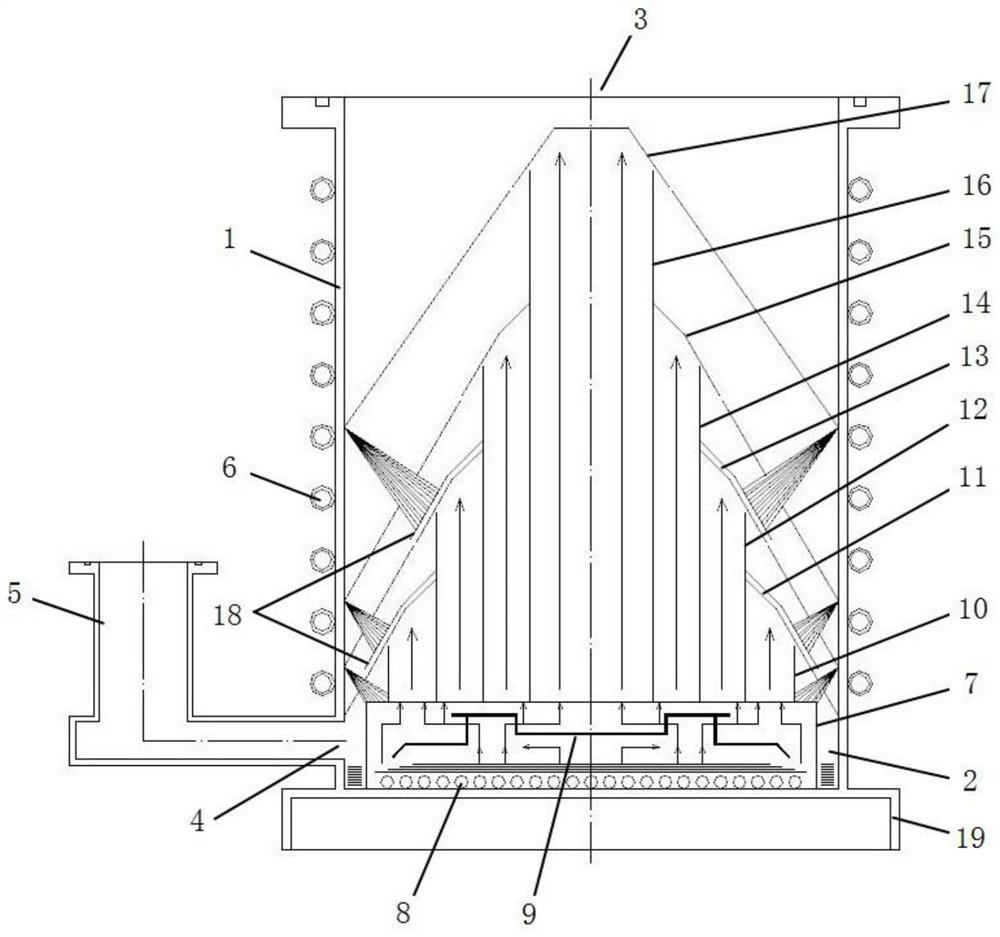

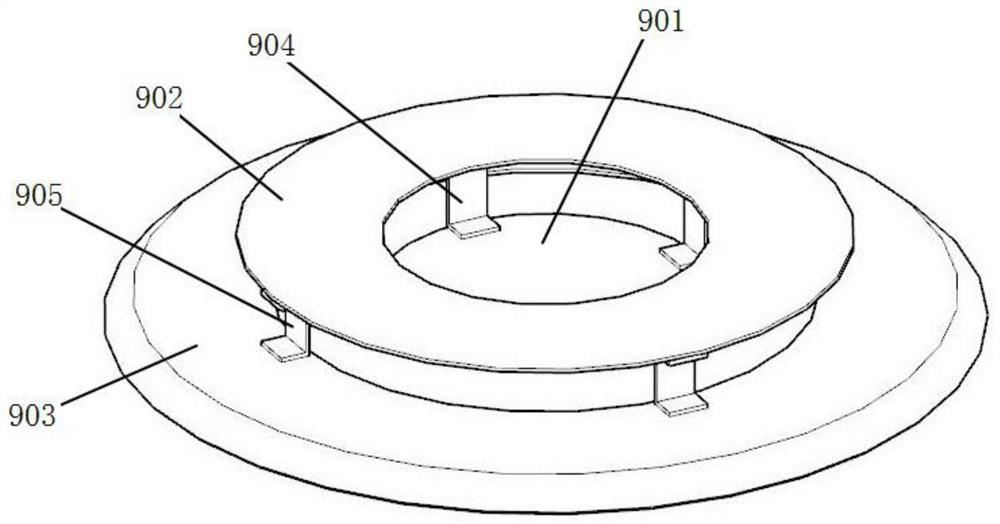

Four-stage fractional distillation type oil diffusion pump with flow distribution plate

PendingCN112412894ALow machining accuracy requiresGuaranteed air tightnessMachines/enginesDiffusion pumpsSpray nozzleEngineering

The invention discloses a four-stage fractional distillation type oil diffusion pump with a flow distribution plate. The four-stage fractional distillation type oil diffusion pump comprises a pump body with a built-in pump core, wherein an oil chamber is arranged at the bottom of the pump body; an air inlet is formed in the upper end of the pump body; a spraying nozzle is arranged at the bottom ofthe side end of the pump body; the spraying nozzle is externally connected with an exhausting pipe; a cooling water pipe is fixed at the periphery of the pump body; a supporting cover is fixed in theoil chamber; the supporting cover is composed of a supporting plate and a cylindrical pipe; the supporting cover is internally provided with a heating pipeline and the flow distribution plate locatedabove the heating pipeline; the flow distribution plate comprises a central blind plate, a first annular end plate and a second annular end plate; and the pump core is fixed at the upper side of thesupporting cover. The four-stage fractional distillation type oil diffusion pump is scientific and reasonable in structural design; the flow distribution plate is additionally arranged in the oil chamber and can be used for pre-guiding fractions, so that the ultimate vacuum degree which can be improved through distillation is increased; and meanwhile, the flow distribution plate is arranged so that the fractions which are volatilized before a boiling point is reached can be effectively intercepted and blocked, and furthermore, an oil returning phenomenon is greatly reduced and the utilizationeffect of the pump body is improved.

Owner:CHANGZHOU LEMENG PRESSURE VESSEL CO LTD

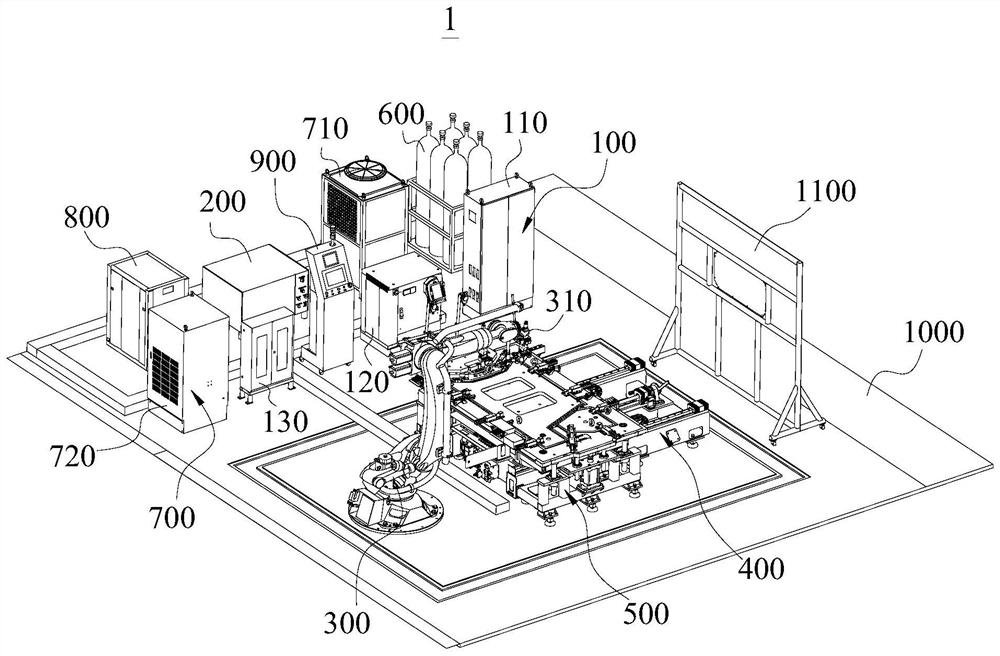

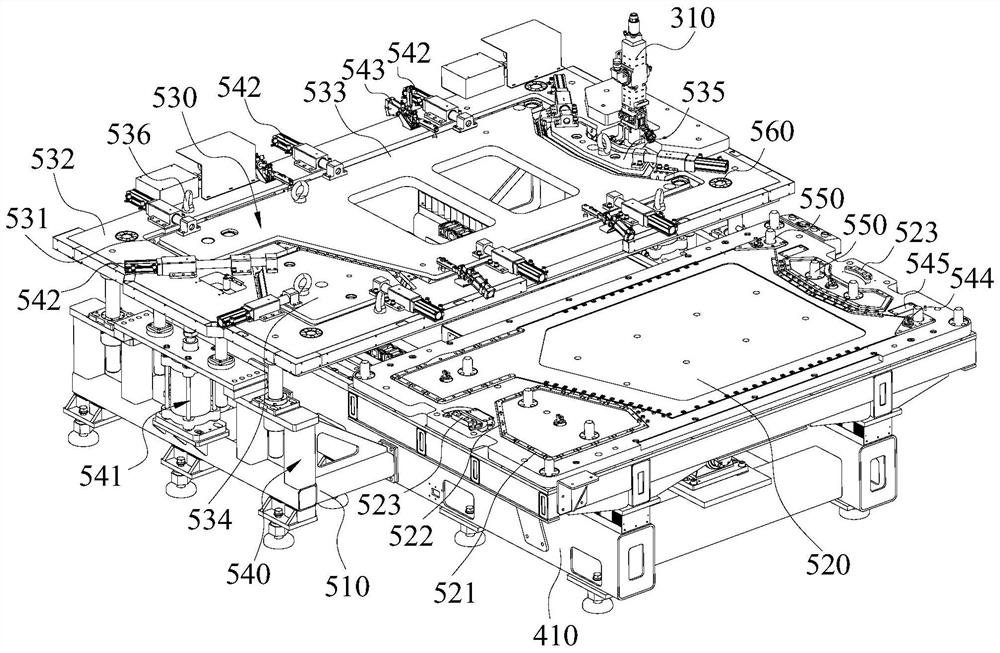

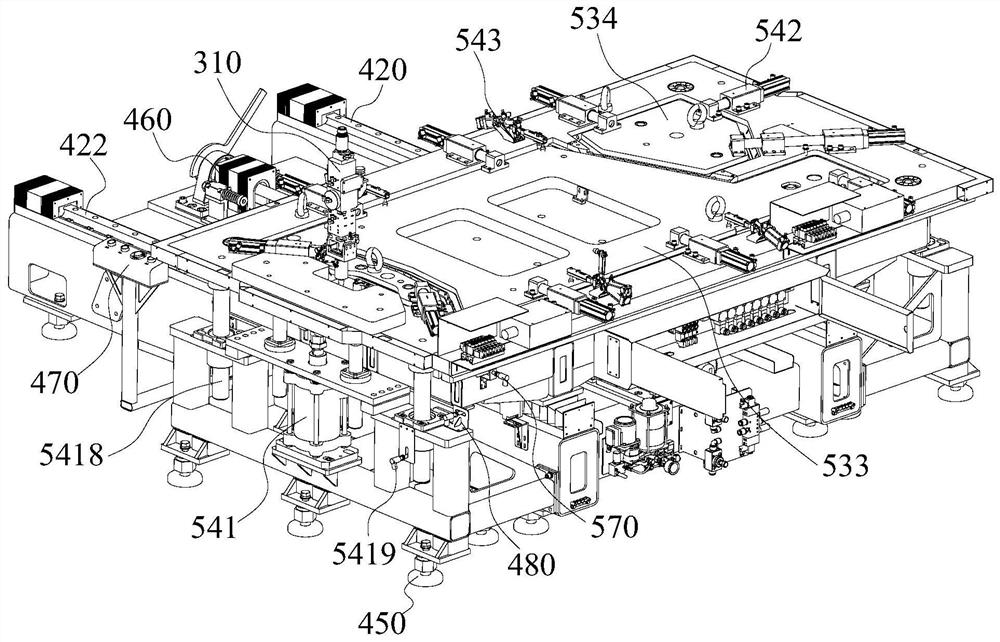

Laser welding system for heat exchange plate

InactiveCN110434462BRealize automatic stitch weldingImprove quality and efficiencyWelding/cutting auxillary devicesAuxillary welding devicesControl systemLaser light

Owner:HANS LASER TECH IND GRP CO LTD +1

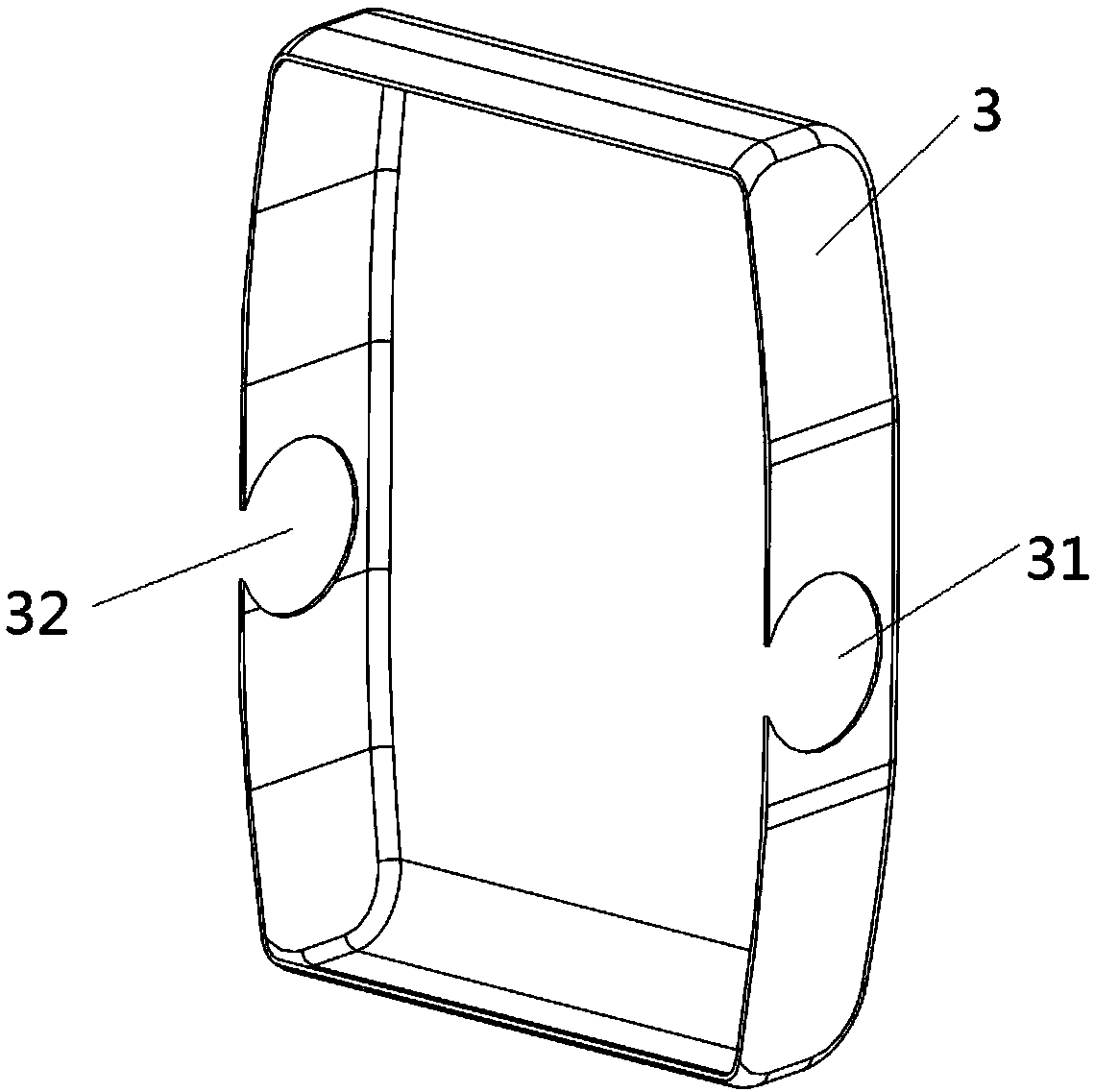

Fluid flow pipe, sensor assembly and Coriolis mass flowmeter

PendingCN109425401AGuaranteed a high degree of symmetrySolve the defect of large difference in flow velocity between inside and outsideDirect mass flowmetersEngineeringFluid input

The invention discloses a fluid flow pipe, a sensor assembly and a Coriolis mass flowmeter. The fluid flow pipe comprises a fluid input pipeline, a fluid output pipeline and a dual-loop pipeline whichis connected between the fluid input pipeline and the fluid output pipeline in series, the dual-loop pipeline comprises a first loop which is connected with the fluid input pipeline and a second loopwhich is connected with the fluid output pipeline, the plane where the first loop is located is parallel to the plane where the second loop is located, and the first loop is connected with the secondloop through a crossover pipeline; the first loop and the second loop are basically in the shape of a rectangle with rounded corners. By forming the first loop and the second loop in the shape of therectangle with rounded corners, the problem that difference value of flow speeds at the inner and outer sides when a fluid material makes a turn is large is solved; meanwhile, during processing, highsymmetry of the dual loops is easily achieved.

Owner:罗凡

Stacked packaging piece with ground ring and processing method of stacked packaging piece

ActiveCN112151510ASave spaceImprove securitySemiconductor/solid-state device detailsSolid-state devicesElectric machineGear wheel

The invention discloses a stacked packaging piece with a grounding ring and a processing method of the stacked packaging piece, and the stacked packaging piece comprises a packaging piece main body, amounting groove, a sliding groove, a guide groove, a first storage groove, a motor, a gear, a rack, a sliding block, a fixed rod, a hinge ferrule, a connecting plate, the grounding ring, a second storage groove and a rotating shaft, and the inner wall of one side of the packaging piece main body is provided with the mounting groove; the motor is distributed and embedded in the inner wall of the bottom end of the mounting groove, the gear is distributed and mounted on the inner wall of one side of the mounting groove, one end of an output shaft of the motor is fixedly connected to the interiorof the gear, and the rack is connected to the outer wall of one side of the gear in a distributed and engaged mode. The stacked packaging piece adopts a grounding ring mode and reduces grounding wireconnection, thus a chip is convenient to install and fix, the space of the packaging piece is reduced, the grounding ring is convenient to install, the welding operation is reduced, a large amount ofharmful gas is prevented from being generated during welding, the environment is prevented from being polluted, and the safety of the packaging piece is improved.

Owner:ANHUI LONGXINWEI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com